Low-magnesium multilayer aluminum alloy brazing expansion material and application thereof

An aluminum alloy, low magnesium technology, used in welding/cutting media/materials, welding media, welding equipment, etc., can solve the problems of gaps in the brazing seam on the outer surface, unsuitable flux components, and blackened product appearance. Achieve the effect of overcoming difficult cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

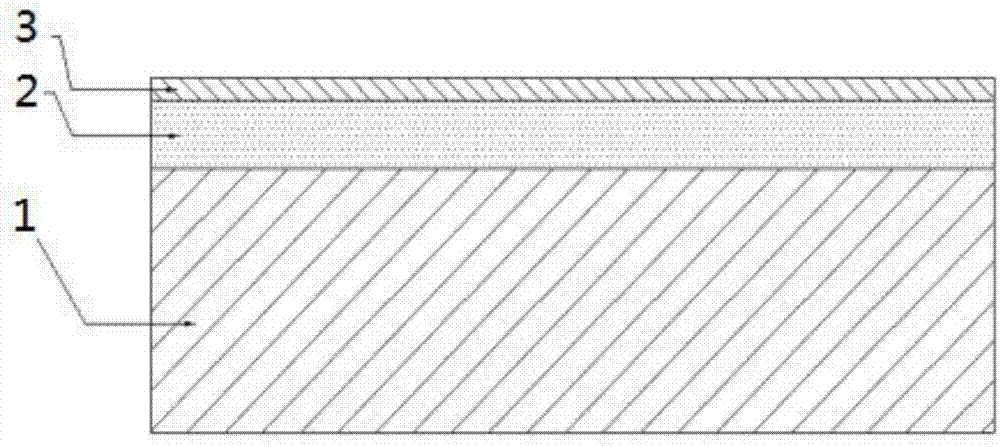

[0052] Such as figure 1 As shown, the low-magnesium multi-layer aluminum alloy brazing expansion material includes sequentially composited core layer 1, brazing layer 2 and cover layer 3;

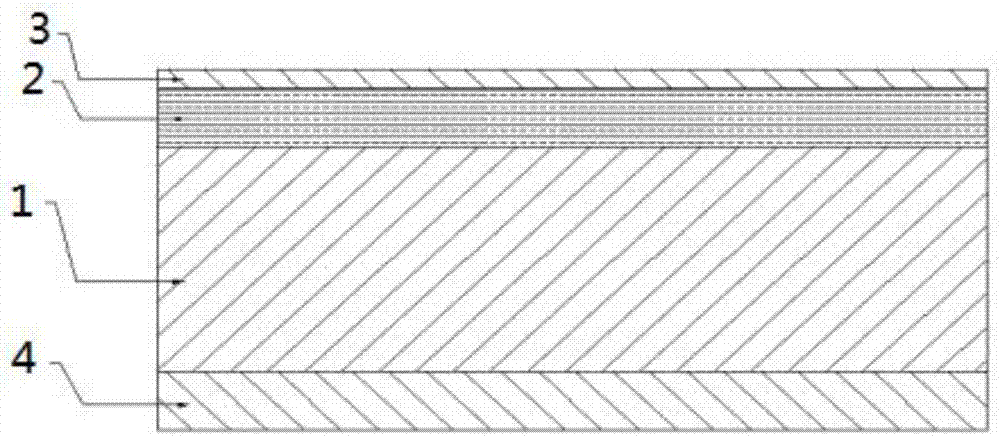

[0053] Such as figure 2 As shown, preferably, the low-magnesium multi-layer aluminum alloy brazing expansion material includes sequentially composited water-contacting layer 4, core layer 1, brazing layer 2 and covering layer 3;

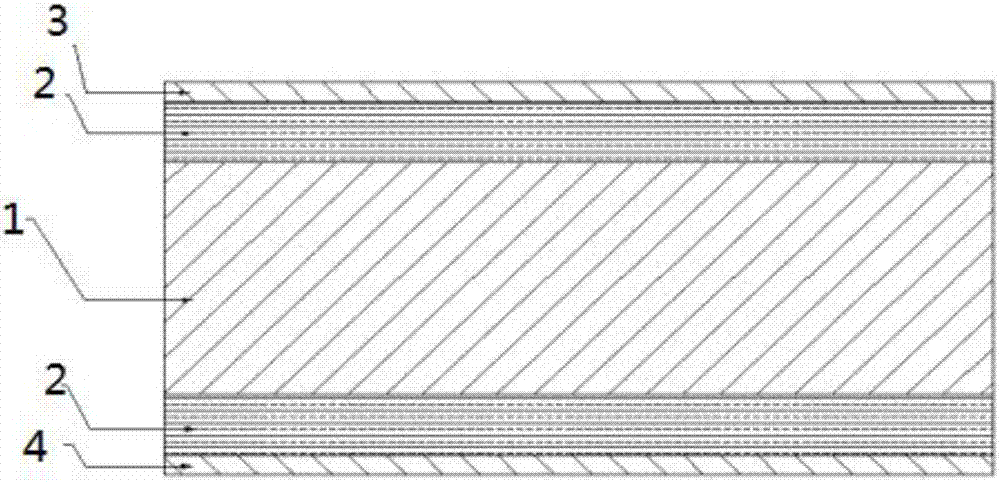

[0054] Such as image 3 As shown, preferably, the low-magnesium multilayer aluminum alloy brazing expansion material includes a core layer 1, a brazing layer 2 and a covering layer 3, and the brazing layer 2 and the covering layer 3 are sequentially compounded on the Both sides of the core layer 1;

[0055] Such as Figure 4 As shown, preferably, the low-magnesium multi-layer aluminum alloy brazing expansion material includes a core layer 1, a brazing layer 2, a covering layer 3 and a water-contacting layer 4, and the brazing layer 2 and the covering layer 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap