Vertical-type scrap iron scraper conveyor

A scraper and iron filing technology, applied in conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of high manufacturing cost, inconvenient cleaning, and many wearing parts, etc. Easy to clean and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

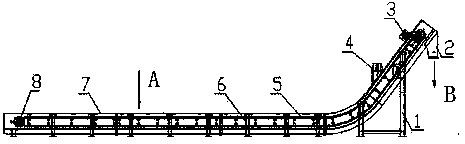

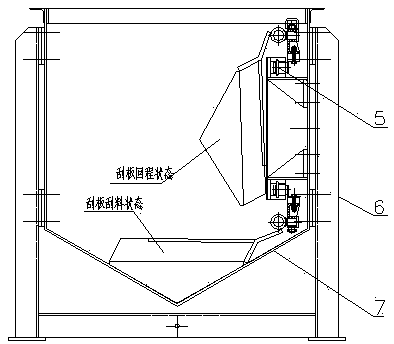

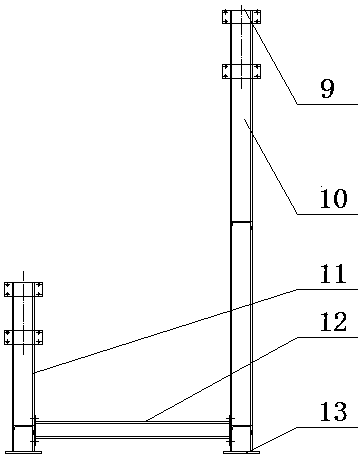

[0028] like Figure 1 to Figure 11 As shown, the vertical iron chip scraper machine includes a high bracket 1, a hopper 2, a main transmission device 3, a lubricating device 4, a scraper device 5, a short bracket 6, a discharge main body 7 and a driven device 8, and a high bracket 1 and the short bracket 6 are respectively connected to the discharge main body 7, the discharge hopper 2 is connected to the discharge main body 7, the main transmission device 3 and the driven device 8 are respectively fixed on both ends of the discharge main body 7, and the lubricating device 4 is fixed on the discharge main body 7. The upper slope of the material body 7 is used to lubricate the chain and prolong the service life of the chain. The scraper device 5 is installed on the material discharge body 7. The high bracket 1 is composed of the first connecting plate 9, the long column 10, and the short column 11. , connecting rod 12, the first anchor plate 13 are welded, and the material of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap