Water closet vertical-pouring molding structure capable of simplifying production process

A technology of forming structure and production process, applied in ceramic forming machines, manufacturing tools, molds, etc., can solve the problems of time-consuming and laborious operation of live blocks in the pot, complicated process operations, and easy breakage of live blocks, and improve the problem of poor glazing. Hidden dangers, improving enterprise efficiency, and the effect of no hygienic dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

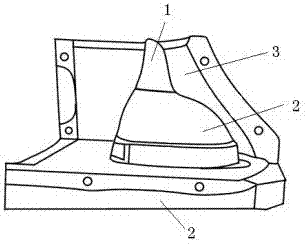

[0019] As shown in the figure, the movable block of the pot internal water area model includes the water seal water storage area active block 1, the circle plate model 2, and the big gang model 3.

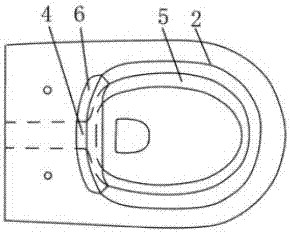

[0020] The figure shows that the water inlet of the toilet circle of the ring plate model 2 cancels the single-sided slurry suction channel and replaces it with a double-sided slurry suction channel 4, and the structure of the double-sided slurry suction channel 4 transitions to both sides and is in phase with the diversion platform 5 Connect, cancel the water retaining edge on the guide platform 5 tops.

[0021] Due to the removal of the water retaining edge, the ring plate model 2 has become an integral structure. If the product is larger, the ring plate model 2 can be changed into one large and one small two loose blocks, which is easy to operate. Due to the cancellation of the water retaining edge, the hidden danger of poor glazing at the lower part of the water retaining edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com