Forming mould and method of soft package trademark liner used for cigarette packaging

A technology of forming dies and forming dies, which is applied in the direction of cardboard articles, etc., can solve the problems of inability to meet the needs of cigarette packaging, complex packaging forming operations, and single structure, and achieve broad market application prospects, low development costs, and high forming efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

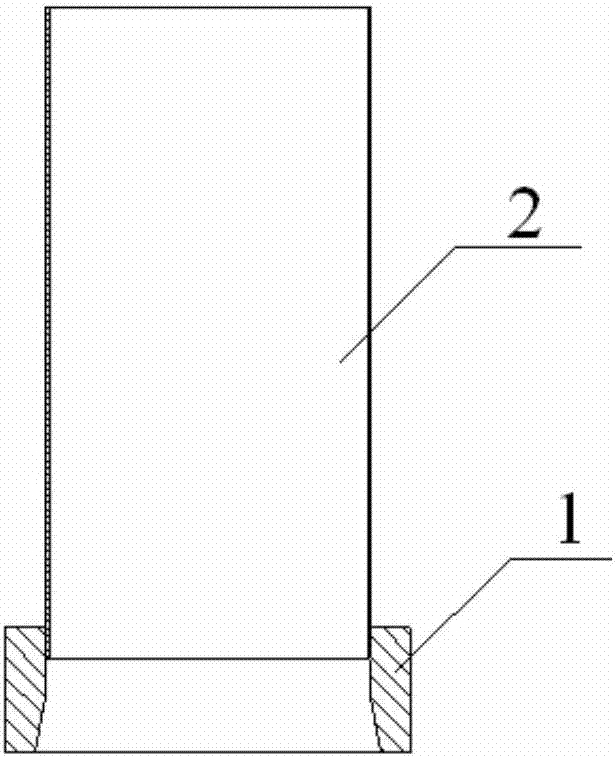

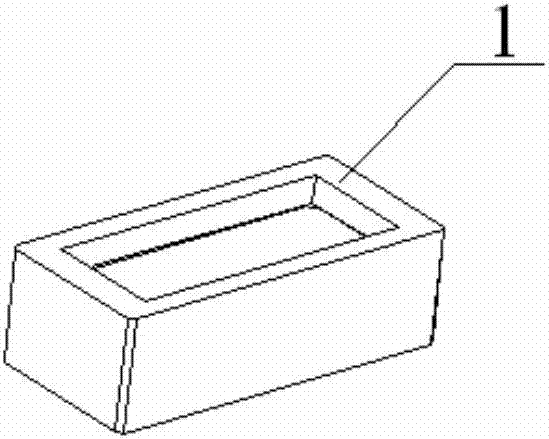

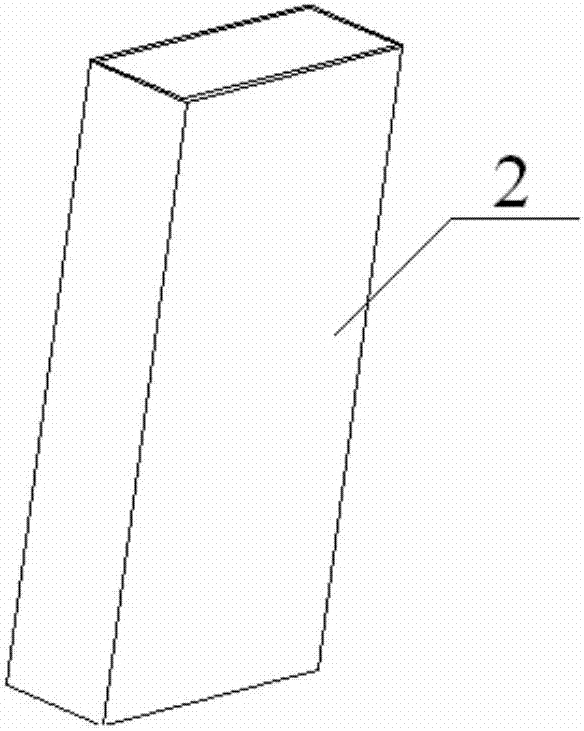

[0031] The invention proposes a mold for forming the inner liner of the soft bag trademark for cigarette packaging, which includes a mold box for forming the side surface of the inner lining of the trademark and a mold box for forming the end surface of the inner lining of the trademark. The mold box for forming the side of the trademark lining includes a guide seat 1 and a hollow mold box 2, as attached figure 1 to attach image 3 As shown, the middle part of the guide seat 1 is provided with a guide through hole, the guide seat preferably has a cuboid structure, and the guide through hole is a rectangular through hole opened along the middle part of the guide seat. A bell mouth stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com