Nib brushing straightening device for ink brush manufacturing

A technique of using a pen and a writing brush, applied in printing, other ink pens, repair of ink pens, etc., can solve the problem of time-consuming and laborious, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

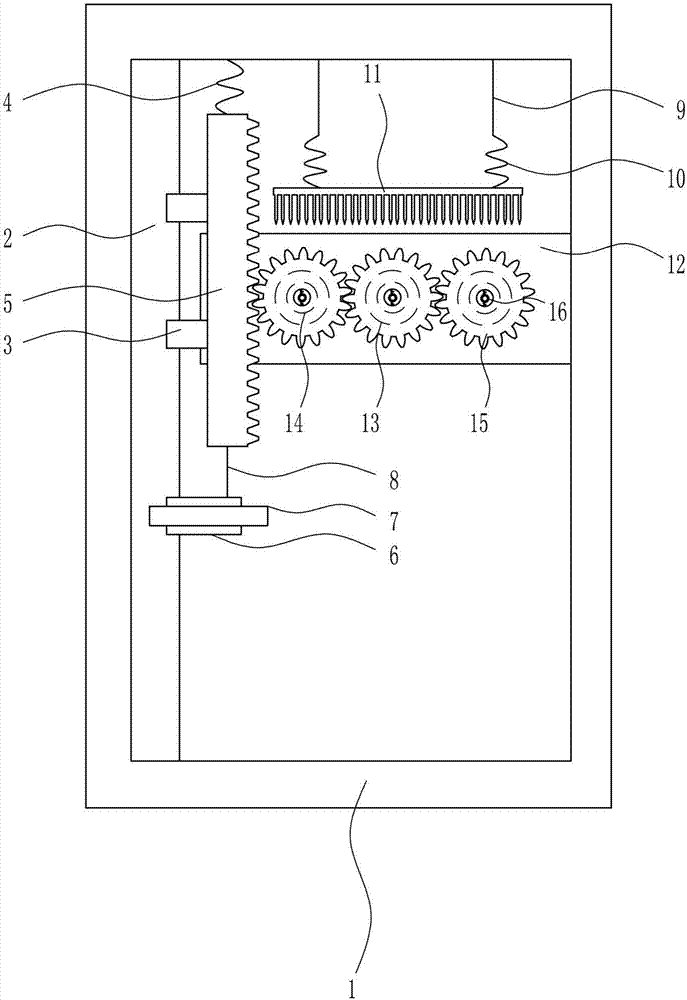

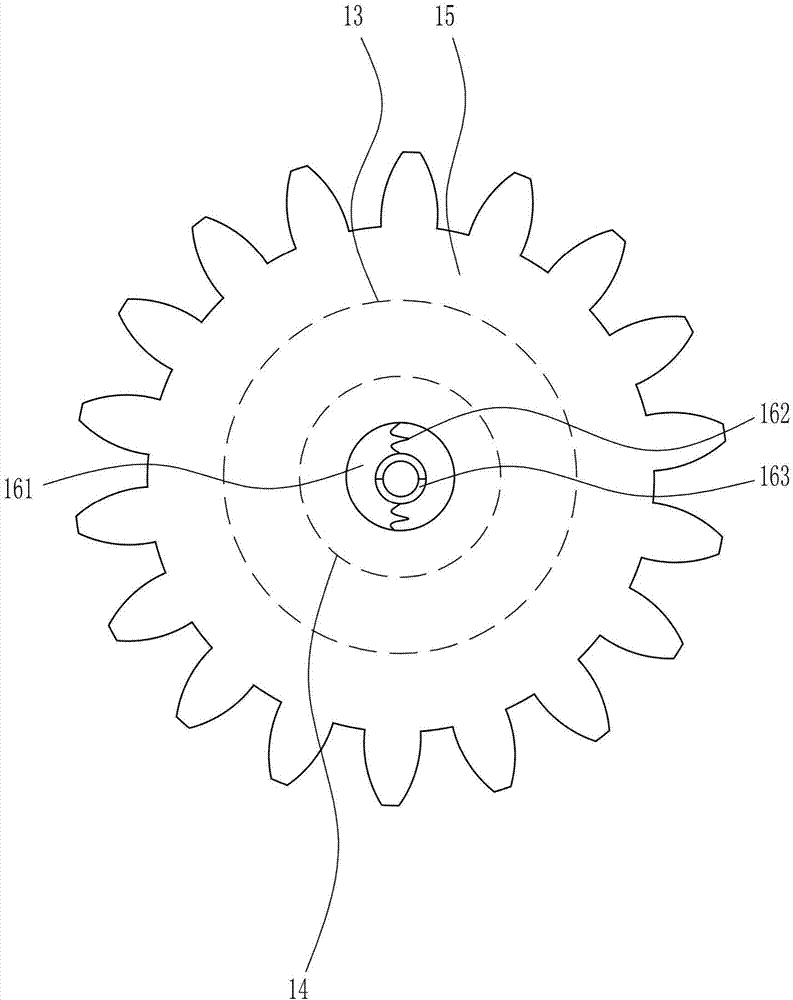

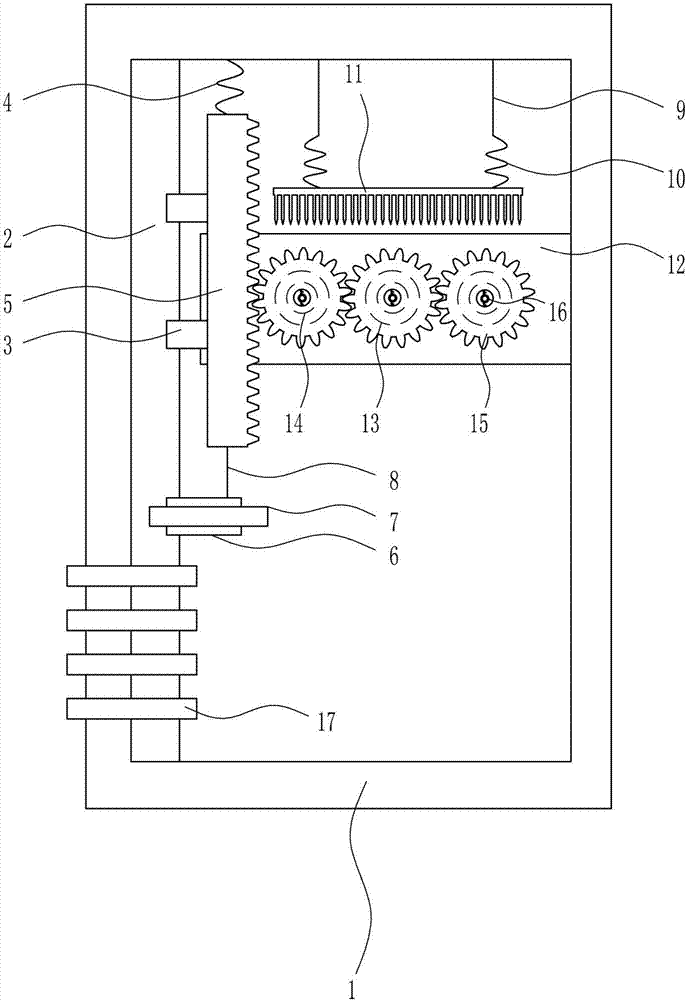

[0028] A brush straightening device for making a brush, such as Figure 1-5 As shown, it includes a mounting frame 1, a slide rail 2, a first slider 3, a first spring 4, a rack 5, a second slider 6, a pedal 7, a first pull wire 8, a second pull wire 9, and a second spring 10. Comb 11, mounting plate 12, bearing seat 13, rotating shaft 14, gear 15 and fixing device 16, the inner left wall of mounting frame 1 is provided with slide rail 2, and the right side of slide rail 2 is slidingly connected with first slider 3, The right side of the first slider 3 is provided with a rack 5, the top of the rack 5 is connected with the first spring 4 between the top left side of the mounting frame 1, the right side of the slide rail 2 is slidably connected with the second slider 6, and The second slider 6 is below the first slider 3, the front side of the second slider 6 is provided with a pedal 7, the first pull wire 8 is connected between the top of the second slider 6 and the bottom end o...

Embodiment 2

[0030] A brush straightening device for making a brush, such as Figure 1-5 As shown, it includes a mounting frame 1, a slide rail 2, a first slider 3, a first spring 4, a rack 5, a second slider 6, a pedal 7, a first pull wire 8, a second pull wire 9, and a second spring 10. Comb 11, mounting plate 12, bearing seat 13, rotating shaft 14, gear 15 and fixing device 16, the inner left wall of mounting frame 1 is provided with slide rail 2, and the right side of slide rail 2 is slidingly connected with first slider 3, The right side of the first slider 3 is provided with a rack 5, the top of the rack 5 is connected with the first spring 4 between the top left side of the mounting frame 1, the right side of the slide rail 2 is slidably connected with the second slider 6, and The second slider 6 is below the first slider 3, the front side of the second slider 6 is provided with a pedal 7, the first pull wire 8 is connected between the top of the second slider 6 and the bottom end o...

Embodiment 3

[0033] A brush straightening device for making a brush, such as Figure 1-5 As shown, it includes a mounting frame 1, a slide rail 2, a first slider 3, a first spring 4, a rack 5, a second slider 6, a pedal 7, a first pull wire 8, a second pull wire 9, and a second spring 10. Comb 11, mounting plate 12, bearing seat 13, rotating shaft 14, gear 15 and fixing device 16, the inner left wall of mounting frame 1 is provided with slide rail 2, and the right side of slide rail 2 is slidingly connected with first slider 3, The right side of the first slider 3 is provided with a rack 5, the top of the rack 5 is connected with the first spring 4 between the top left side of the mounting frame 1, the right side of the slide rail 2 is slidably connected with the second slider 6, and The second slider 6 is below the first slider 3, the front side of the second slider 6 is provided with a pedal 7, the first pull wire 8 is connected between the top of the second slider 6 and the bottom end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com