Method and system for calculating the remaining service life of mechanical equipment under multiple working conditions

A technology of mechanical equipment and calculation method, which is applied in the calculation method and system field of the remaining service life of mechanical equipment, which can solve the problems such as the inability to accurately predict the remaining service life of mechanical equipment, and achieve the effect of accurate remaining service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

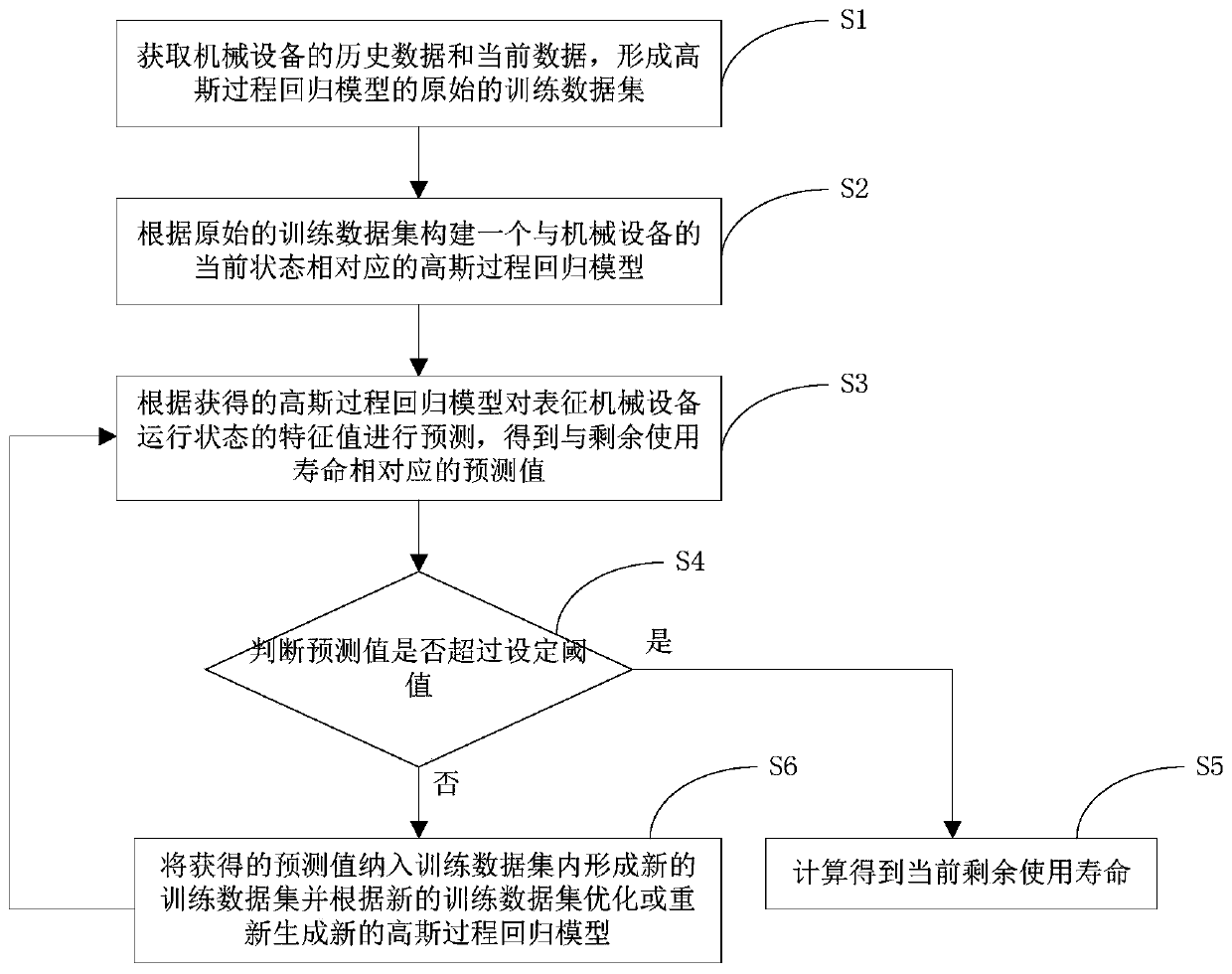

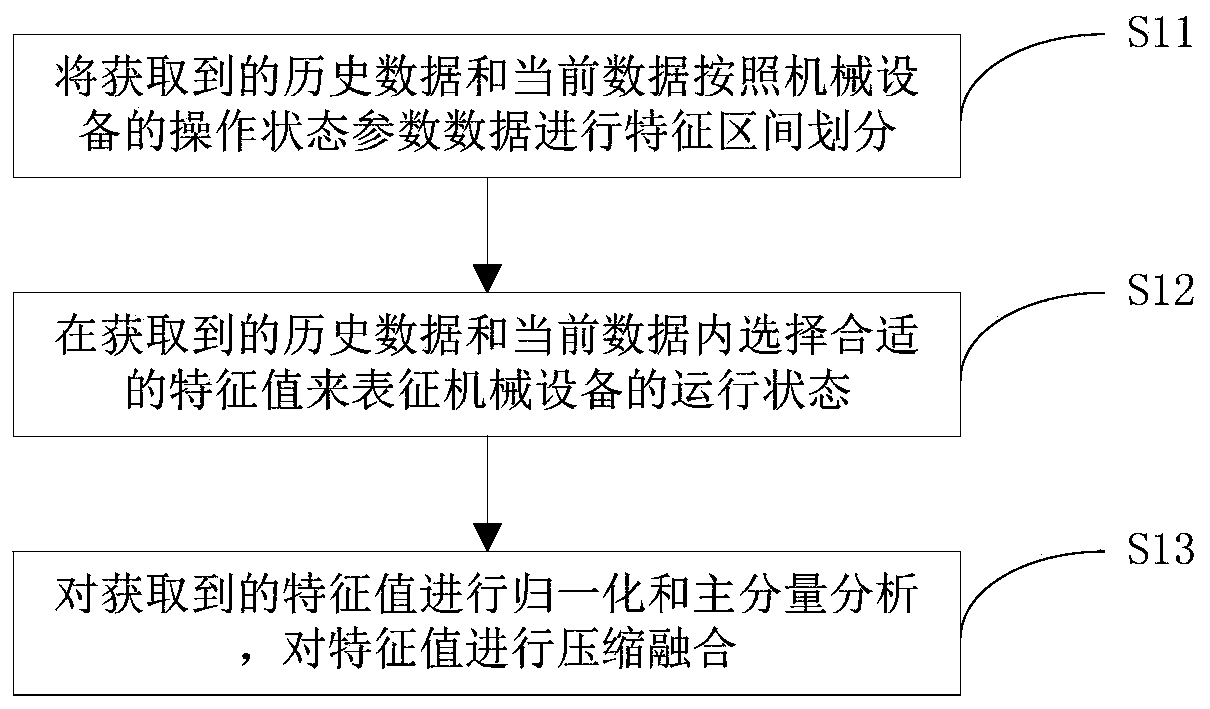

Method used

Image

Examples

Embodiment 2

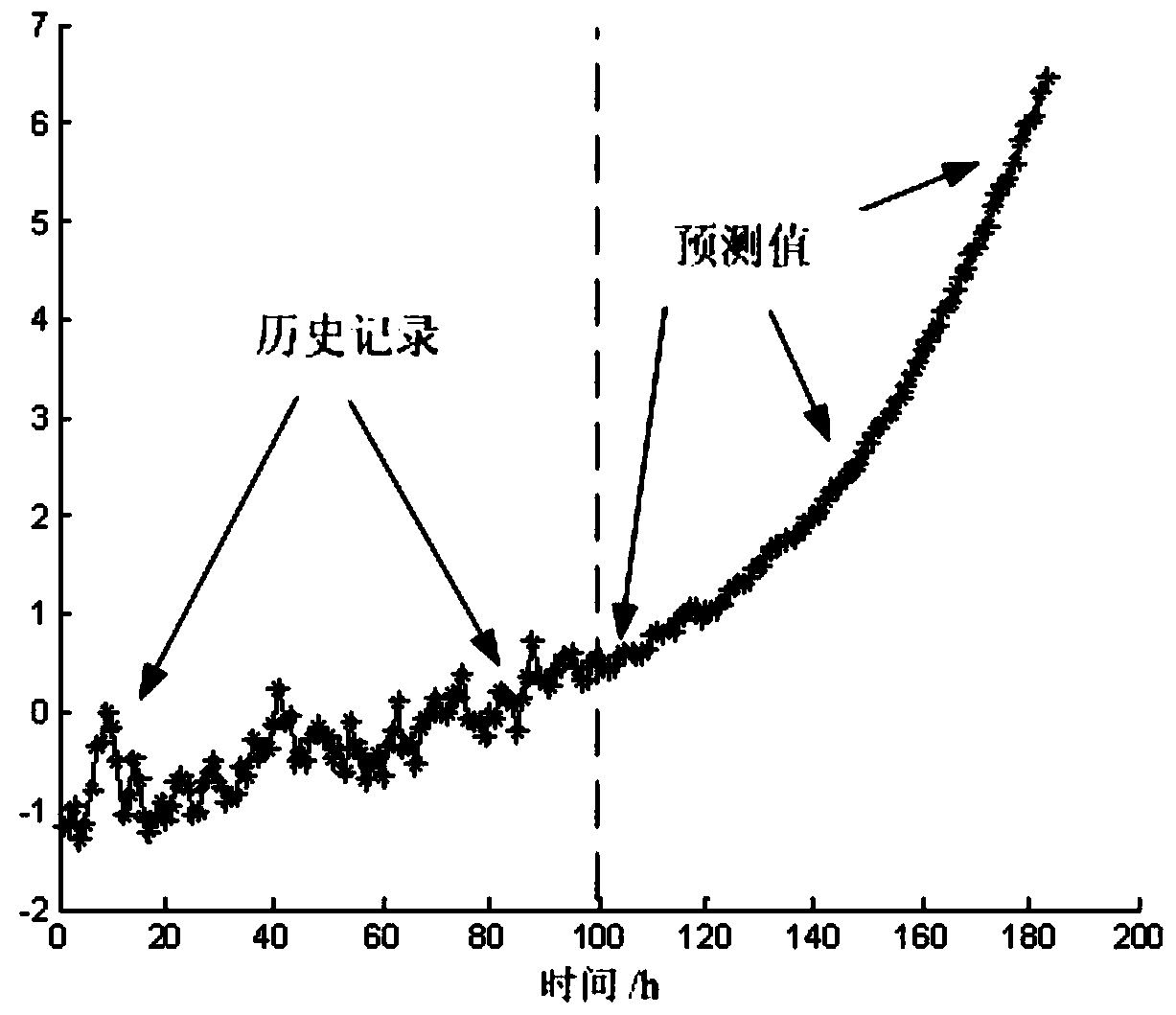

[0071] In this embodiment, by simulating the decay process of an engine, the method for calculating the remaining service life of mechanical equipment under multiple working conditions provided by the present invention is compared with the very common ARMA (Auto-Regressive and Moving Average Model) model and the Elam neural network model ( The comparative analysis of the ENN model for short).

[0072] In this embodiment, the entire decay process of a certain engine is simulated by computer. Such as Figure 7 As shown, the abscissa in the figure is time, the interval between two adjacent data is 10 hours, and the entire life cycle of the engine is 1391 hours, because at the 1391st hour, the characteristic value is lower than the set threshold of 20. The entire decay process of this engine contains 3 internal decay modes, Figure 7 The middle area a1 is the first decline mode, the area a2 is the second decline mode, and the area a3 is the third decline mode, which can be expre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com