Multi-degree-of-freedom hybrid drive artificial muscle

A hybrid drive and artificial muscle technology, applied in the fields of bionics, smart materials, and pneumatic muscles, can solve problems such as heating troubles, insufficient muscle strength of fishing lines, etc., and achieve high power-to-weight ratio, increased bending freedom, and good flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

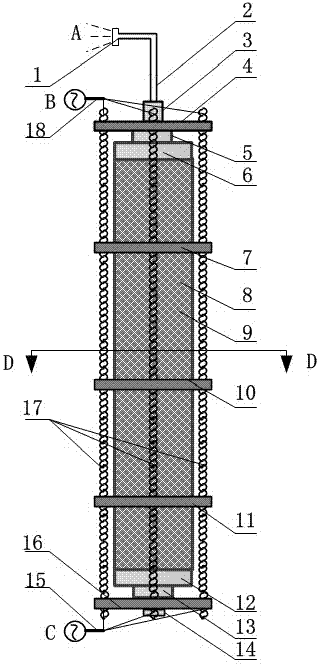

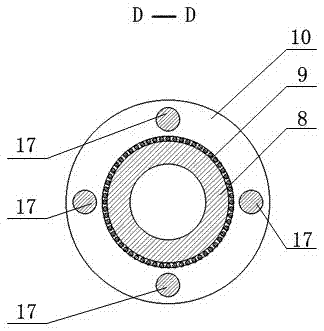

[0018] figure 1 It is a schematic diagram of a multi-degree-of-freedom hybrid-driven artificial muscle structure. The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] A. A layer of PET braided mesh is installed outside the elastic rubber tube, and the two ends are sealed and fastened by inner plug members and outer clamps. In addition, there is a threaded through hole in the middle of the inner plug member for front-end sealing, and the pneumatic joint is connected by thread connection, and the pneumatic joint is connected to the external air pipe to inflate and deflate the rubber pipe. There is a threaded hole with a certain depth on the inner plug member for sealing the rear end, and the rear end fixing frame is fixed by screwing in the screw.

[0020] B. The initial braiding angle of the braided net outside the elastic rubber tube is greater than 54°, which satisfies the requirement tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com