Heating tube and processing process thereof

A heating tube and process technology, applied in the field of heating tube and its processing technology, can solve the problems of tube explosion, aluminum tube fracture, low plasticity of aluminum layer, etc., and achieve the effects of reducing production cost, avoiding bending fracture, and large bending freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

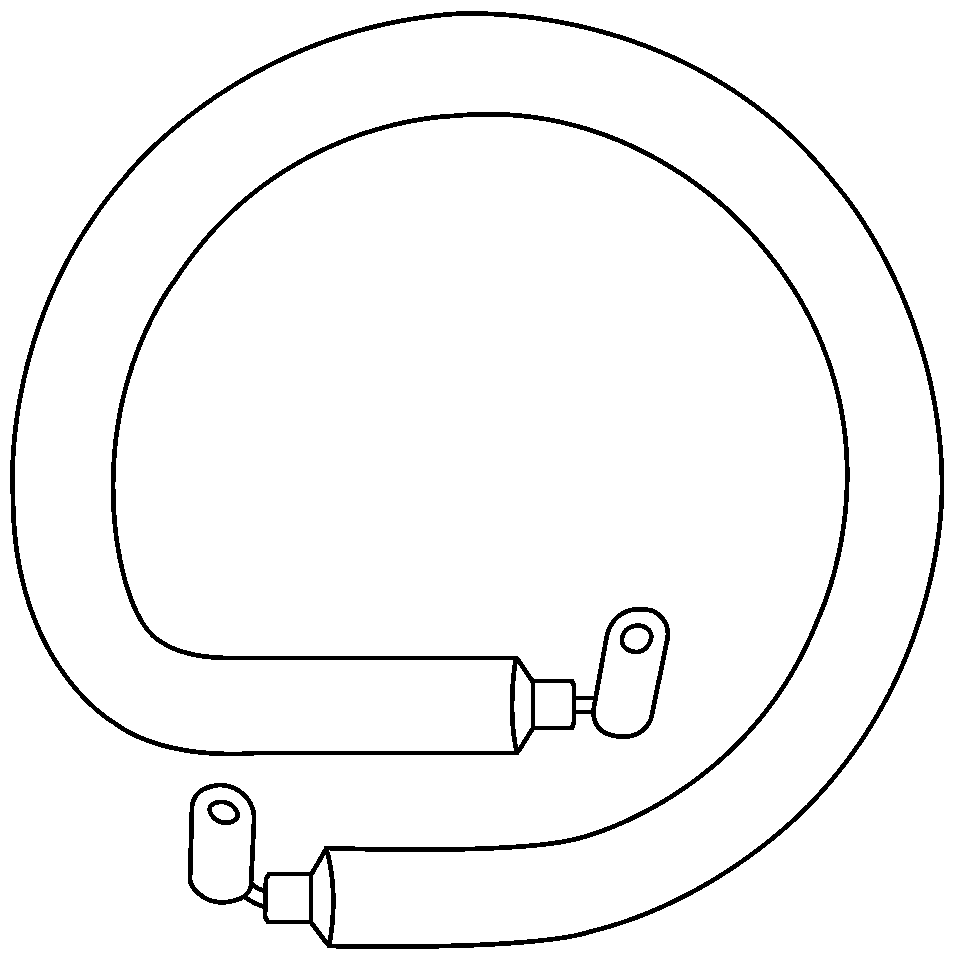

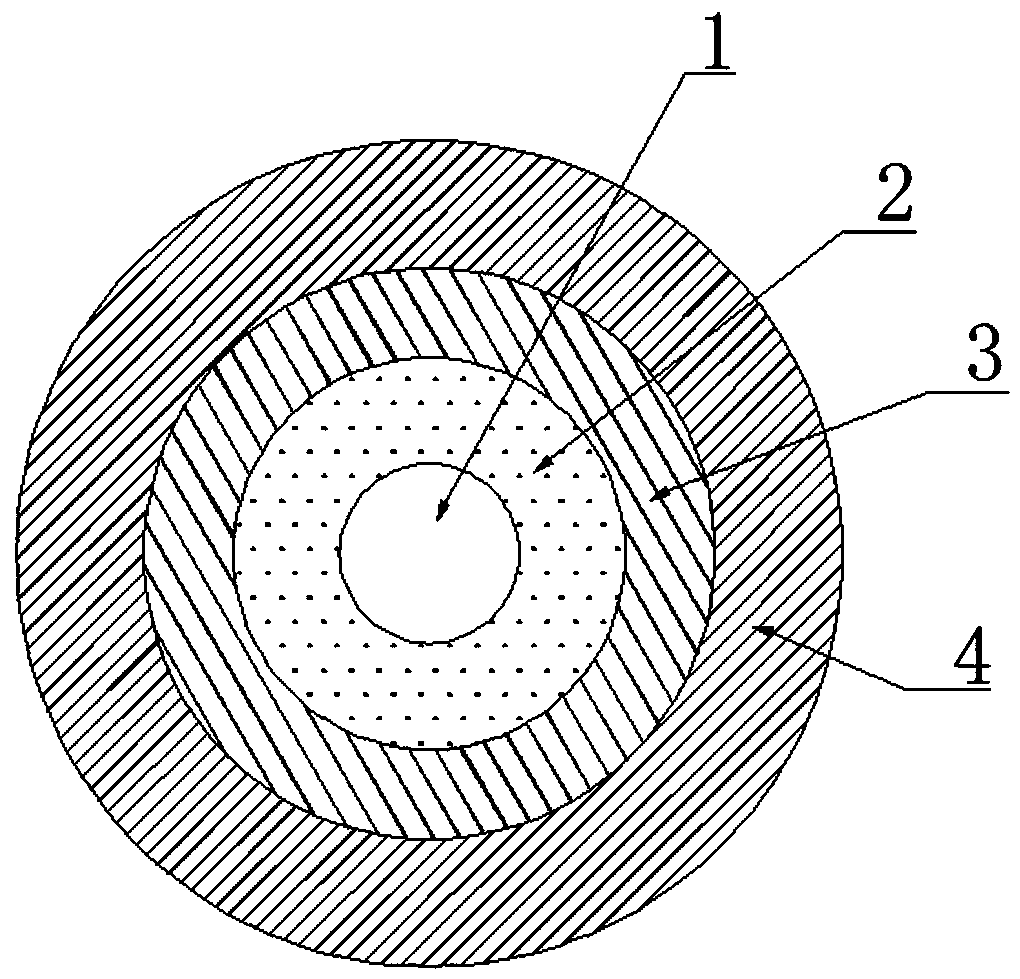

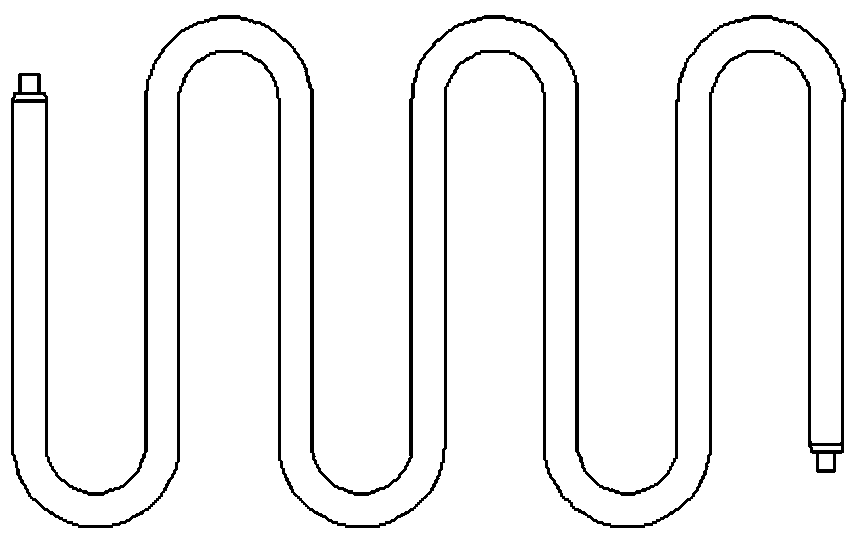

[0017] Such as figure 1 and figure 2 As shown, a heating tube includes a heating wire (1), and the heating wire (1) is covered with a first metal tube (3) with a high melting point and high plasticity. The first metal tube may be a stainless steel tube; The tube (3) is filled with magnesium oxide powder (2) for insulation and heat conduction; the first metal tube (3) is also covered with a second metal tube (4) with a low melting point, and the second metal tube Can be aluminum tube.

[0018] The second metal tube of the heating tube has a low melting point and can be easily and conveniently welded on the chassis of the electric kettle, while the second metal tube is provided with a first metal tube with a high melting point and high plasticity inside the second metal tube. After the heat pipe is partially melted due to high working temperature, the first metal pipe will not melt due to its high melting point, and still protects the inside of the heat pipe to prevent the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com