Spiral loosening knife device of coal bunker

A knife device and loosening technology, applied in packaging, transportation and packaging, containers and other directions, can solve problems such as difficulty in starting, high work intensity, engineering shutdown accidents, etc., to solve the single form of loosening, expand the scope of loosening, and ensure stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

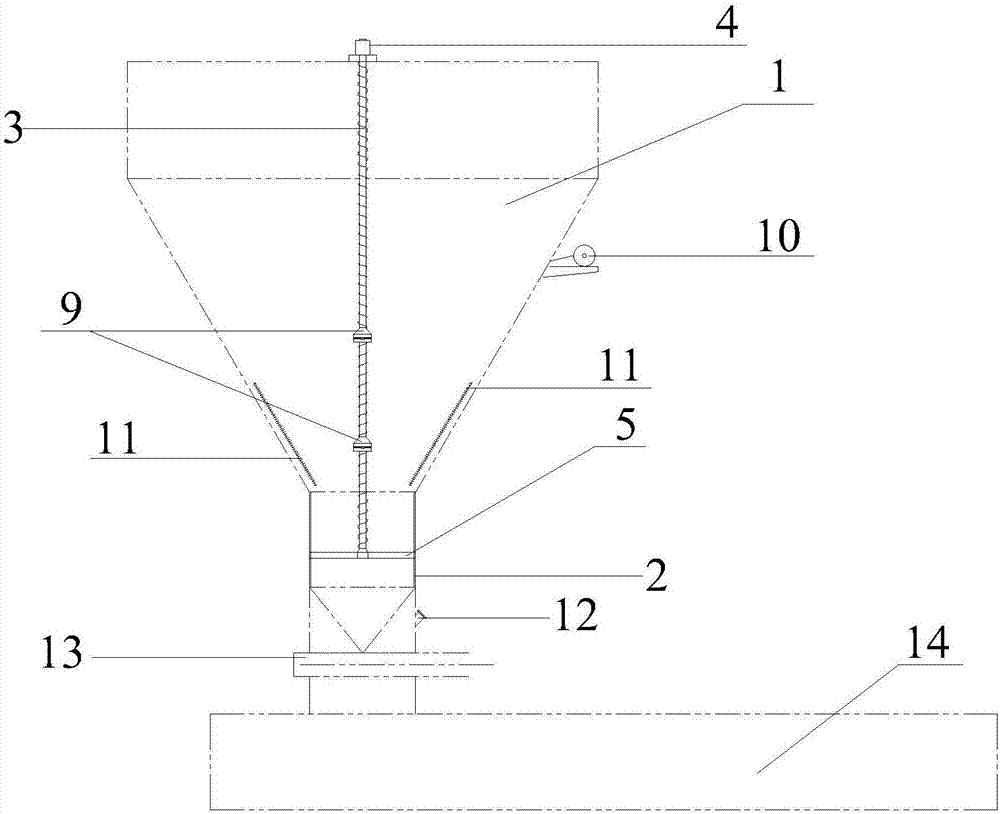

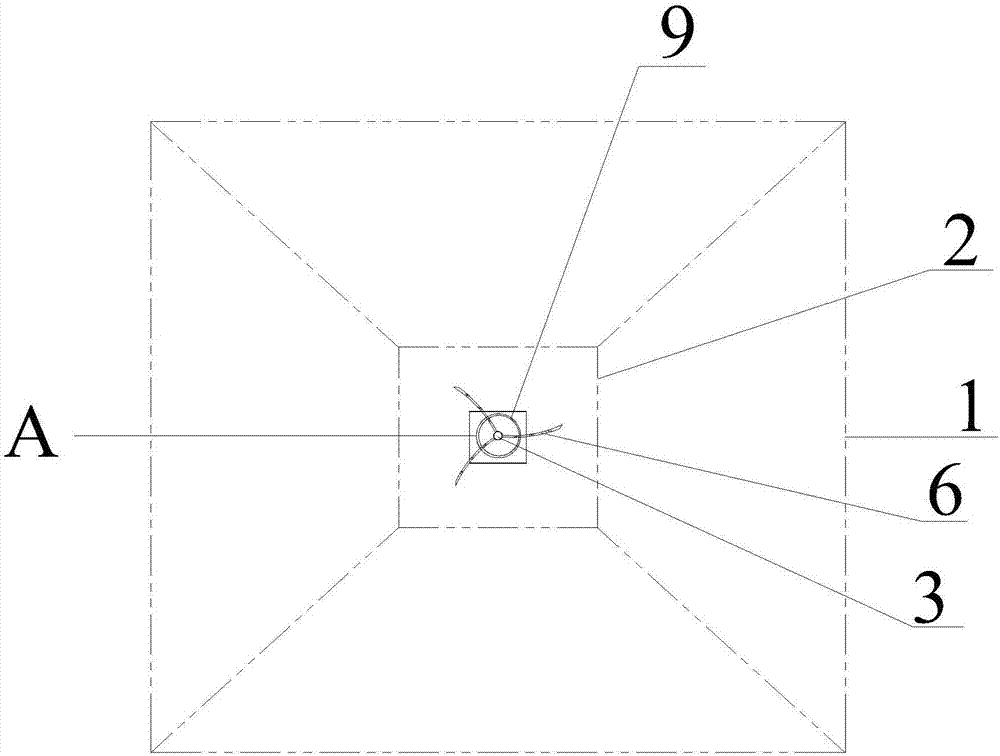

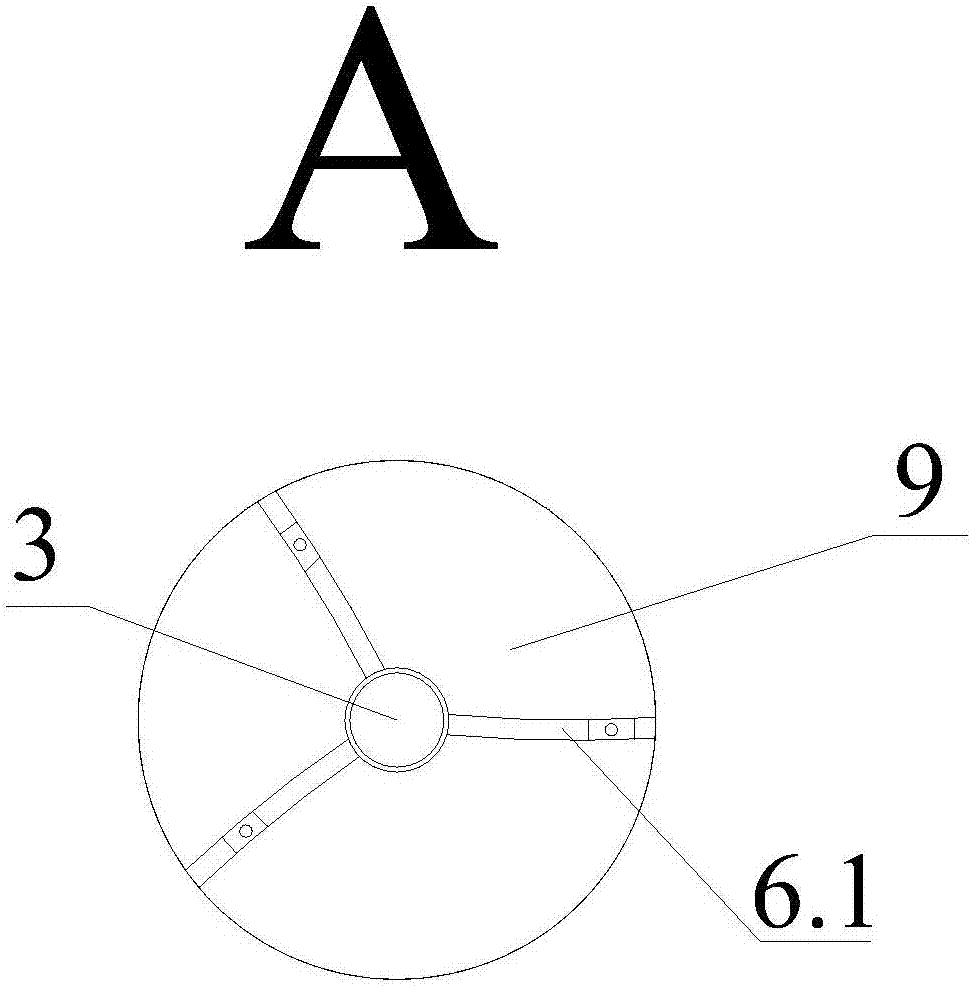

[0030] Such as figure 1 The coal bunker spiral loosening knife device shown in —8 includes a coal bunker 1, a falling pipe 2 connected to the bottom of the coal bunker 1, and a loosening rod 3. The top of the coal bunker 1 is fixed with a driving motor 4, and the falling pipe 2 is fixed inside There is a loose rod guide base 5, the loose rod 3 is arranged between the drive motor 4 and the loose rod guide base 5, the loose rod guide base 5 includes a base sleeve 5.1, and the circumferential interval of the base sleeve 5.1 is fixedly connected with a base connecting rod 5.2 , the end of the base connecting rod 5.2 is fixed on the inner wall of the drop tube 2; the bottom of the loose rod 3 is fixed with a guide shield 15, and the bottom of the guide shield 15 has a positioning groove that matches the base sleeve 5.1, and the base sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com