A method for preparing benzyl alcohol by directional decomposition of benzyl peroxide

A technology of benzyl peroxide and benzyl alcohol, which is applied in the preparation of hydroxyl compounds, the preparation of organic compounds, the separation/purification of hydroxyl compounds, etc., and can solve the problems of chlorine in products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

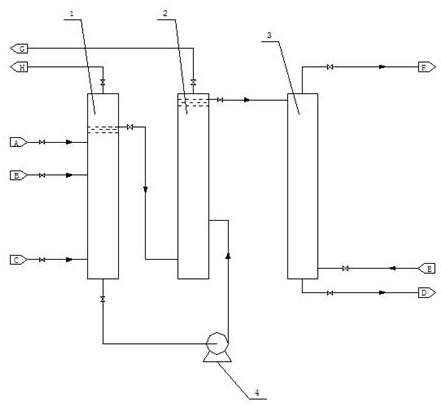

Image

Examples

Embodiment 1

[0026] Embodiment 1 A method for preparing benzyl alcohol by directional decomposition of benzyl peroxide comprises the following steps:

[0027] (1) First order decomposition reaction

[0028] The benzyl peroxide solution that the concentration that catalyzer triphenylphosphine, toluene liquid phase air oxidation reaction generate is 23% (wt) is sent in the primary decomposition reactor 1 continuously, in the decomposition reaction process, add The pH regulator sodium hydroxide adjusts the pH value of the reaction solution to 7.5, while controlling the temperature to 90°C, the pressure to 1.3MPa(G), and the residence time of the reaction solution to 30min. Under the action of the catalyst, the benzyl peroxidation in the reaction solution The directional decomposition of the substance is benzyl alcohol, and the conversion rate of benzyl peroxide in the primary decomposition reactor is 88% (wt). A small amount of non-condensable gas, and some acidic substances are neutralized ...

Embodiment 2

[0035] Embodiment 2 A method for preparing benzyl alcohol by directional decomposition of benzyl peroxide comprises the following steps:

[0036] (1) First order decomposition reaction

[0037] The benzyl peroxide solution of 25% (wt) that the concentration that catalyst tert-butyl chromate, toluene oxidation reaction generate is sent in the primary decomposition reactor 1 continuously, in the decomposition reaction process, add pH value Regulator potassium carbonate adjusts the pH value of the reaction solution to 8, while controlling the temperature to 100°C, the pressure to 1.5MPa(G), and the residence time of the reaction solution for 35 minutes. Under the action of the catalyst, the benzyl peroxide in the reaction solution decomposes directionally It is benzyl alcohol, and the conversion rate of benzyl peroxide in the primary decomposition reactor is 90% (wt). At the same time, in the primary decomposition reactor, the benzyl peroxide solution with higher pressure contain...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap