A wet coal mine dust collector

A technology for dust collectors and coal mines, applied in the fields of coal mine dust collectors and wet coal mine dust collectors, can solve the problems of complicated operation, long dust removal circuit, and many erection equipment, etc., and achieve the effects of convenient processing, improving work efficiency and beautifying the work environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

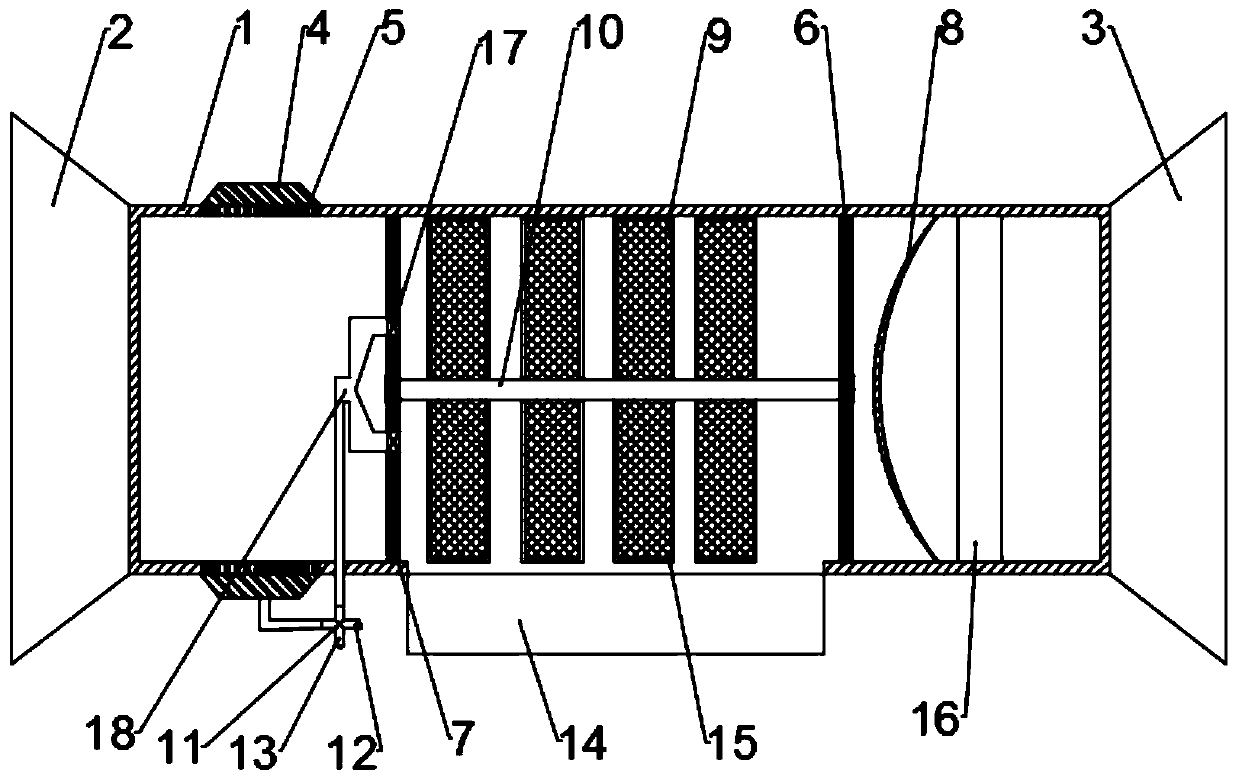

[0018] Referring to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention include the shape, structure, mutual position and connection relationship of each part, the function and working principle of each part, and the manufacturing process of the various components involved. And the method of operation and use, etc., are described in further detail to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

[0019] Such as figure 1 As shown, the present invention provides a wet coal mine dust collector, comprising a casing 1, a dust collection hood 2, and an exhaust hood 3, and the dust collection hood 2 and the exhaust hood 3 are respectively installed at the left and right ends of the casing 1 , so that the dust collector forms the working effect of the Venturi tube as a whole.

[0020] An outer jacke...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap