Wind power big ball milling process

A technology of grinding balls and large balls, which is applied to spherical grinders, grinding machines, manufacturing tools, etc. It can solve problems such as unstable pressure, aging oil seals, and large amount of equipment maintenance, so as to reduce production costs, improve product quality, and beautify the working environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

[0028] The wind power large ball milling ball process of the present invention is realized through the following steps:

[0029] S1: First, add the wind power ball 4 into the special hard grinding device,

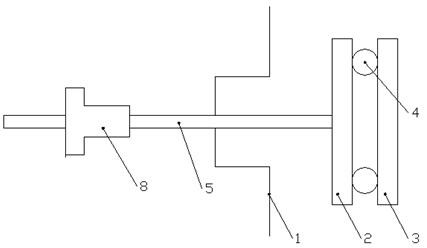

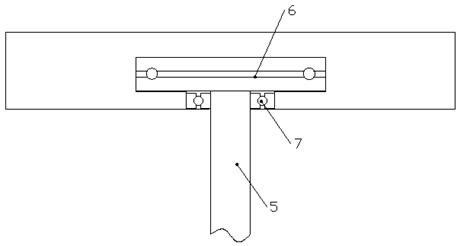

[0030] Such as Figure 1-Figure 2 As can be seen from the schematic diagram shown, the hard grinding device includes

[0031] A grinding ball frame 1, a pair of dynamic grinding ball plates 2 and static grinding ball plates 3 are installed on the grinding ball frame 1, and a wind power capacity is left between the dynamic grinding ball plates 2 and the static grinding ball plates 3 The gap that the big ball 4 fills has an entrance and a ball outlet at one end of the static grinding ball plate 3, and the static grinding ball plate 3 is driven by a ball grinding motor to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap