Transfer vehicle for plastic machine enclosures

A plastic casing and transfer car technology, applied in the transfer car field, can solve the problems of easy loss, laborious manual handling, poor working environment, etc., and achieve the effects of convenient use and recording, beautifying the working environment and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

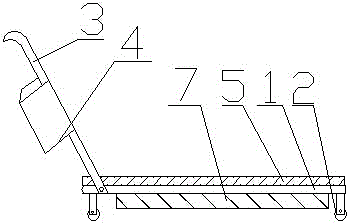

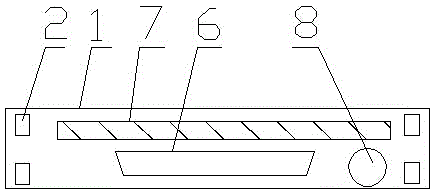

[0011] The invention provides a transfer vehicle with a plastic casing, which includes a base 1, universal wheels 2, a push armrest 3, an accessory box 4, a buffer layer 5, a dust collection box 6, a vacuum cleaner 7, and a power supply device 8, and a vacuum cleaner is installed under the base 1 7. A power supply device 8 and a dust collection box 6 are respectively installed on the rear of the vacuum cleaner 7. One end of the vacuum cleaner 7 is connected to the power supply device 8, and the other end is connected to the dust collection box 6. Universal wheels 2 are installed on the four corners of the bottom of the base 1. One side of the base 1 is connected with the push armrest 3, the accessory box 4 is fixed on the push armrest 3, and the buffer layer 5 is installed above the base 1.

Embodiment 2

[0013] During use, push the present invention to the specified position by pushing the armrest 3, take out the labor protection article from the accessories box 4, put the processed workpiece on the base 1, and because the buffer layer 5 is installed on the base 1, the workpiece and the base 1 can be effectively reduced. The impact force generated by the contact not only improves the service life of the base 1, but also protects the workpiece, avoids damage to the workpiece caused by bumping, records data after loading, and puts the record book in the accessory box 4, and pushes the invention by pushing the armrest 3, During the running process, the power supply device 8 can be turned on, and the vacuum cleaner 7 works. During the running process, the dust and processing waste are absorbed and collected in the dust collecting box 6, which can be dumped regularly. The invention is simple in structure and easy to operate, not only can facilitate workers to carry the workpiece, bu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap