Non-woven fabric stain detection system and non-woven fabric stain detection method

A detection system and non-woven fabric technology, which is applied in the direction of optical testing for flaws/defects, can solve the problems of easy false positives and difficult to detect stains correctly, and achieve the effect of uniform shooting and improved image clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated.

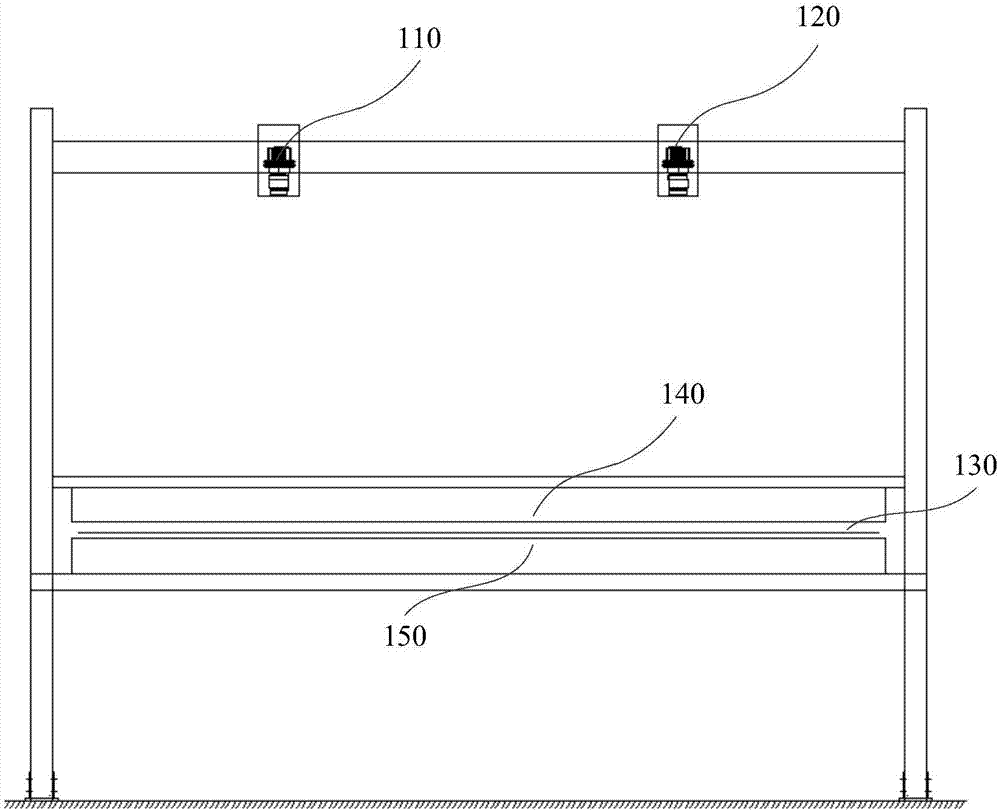

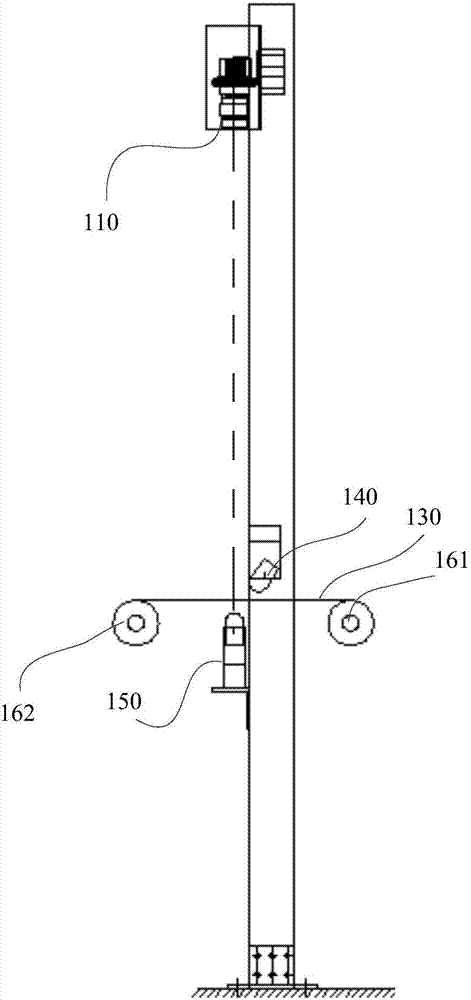

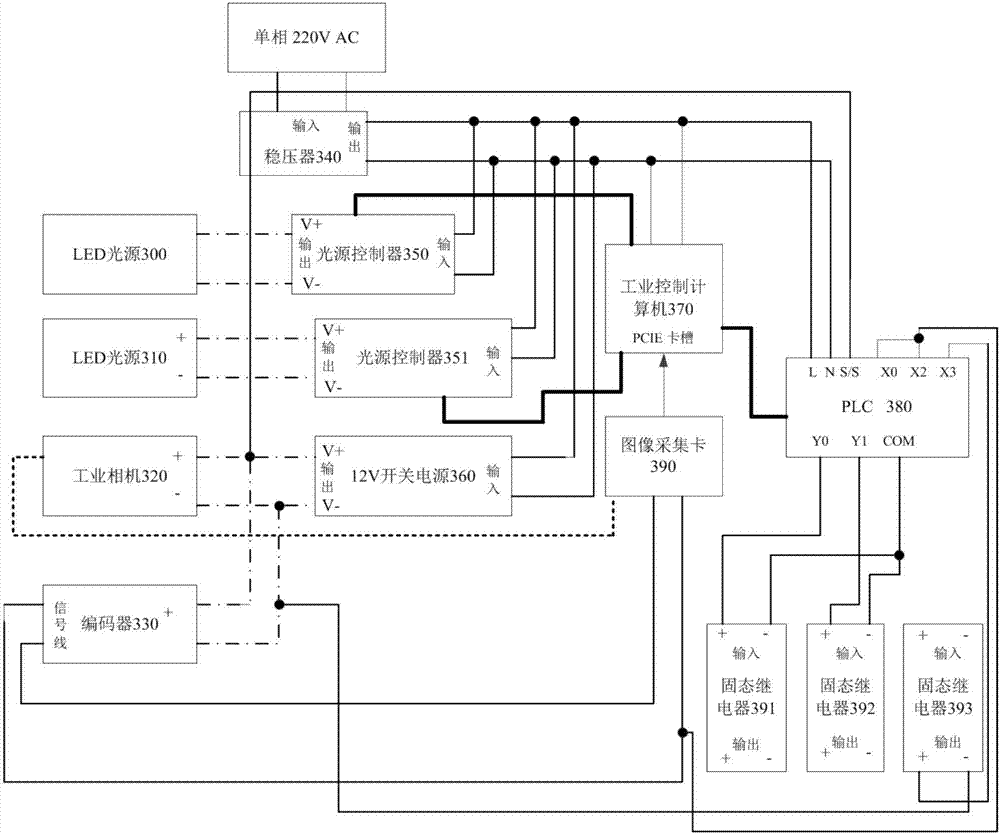

[0052] Please refer to figure 1 , figure 2 with image 3 , which shows a non-woven stain detection system provided by an embodiment of the present invention, the non-woven stain detection system includes two LED (Light Emitting Diode, light emitting diode), industrial camera, industrial control computer, image acquisition card, PLC (Programmable Logic Controller, programmable logic controller) and encoder.

[0053] One LED light source is located above the cloth surface of the non-woven fabric, and the other LED light source is located below the cloth surface o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap