Real-time wood dust monitoring device and method based on minimum ignition energy prediction

A technology of real-time monitoring and ignition energy, applied in the field of wood science, can solve the problems of non-existence and difficulty in real-time measurement, and achieve the effects of high accuracy, saving explosion-proof costs, and reducing the probability of false alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

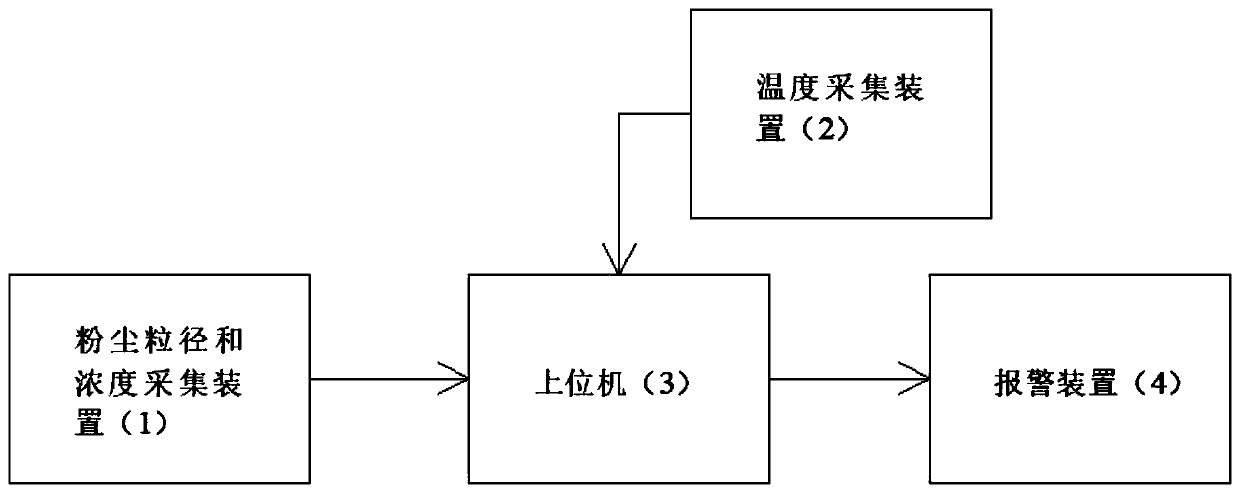

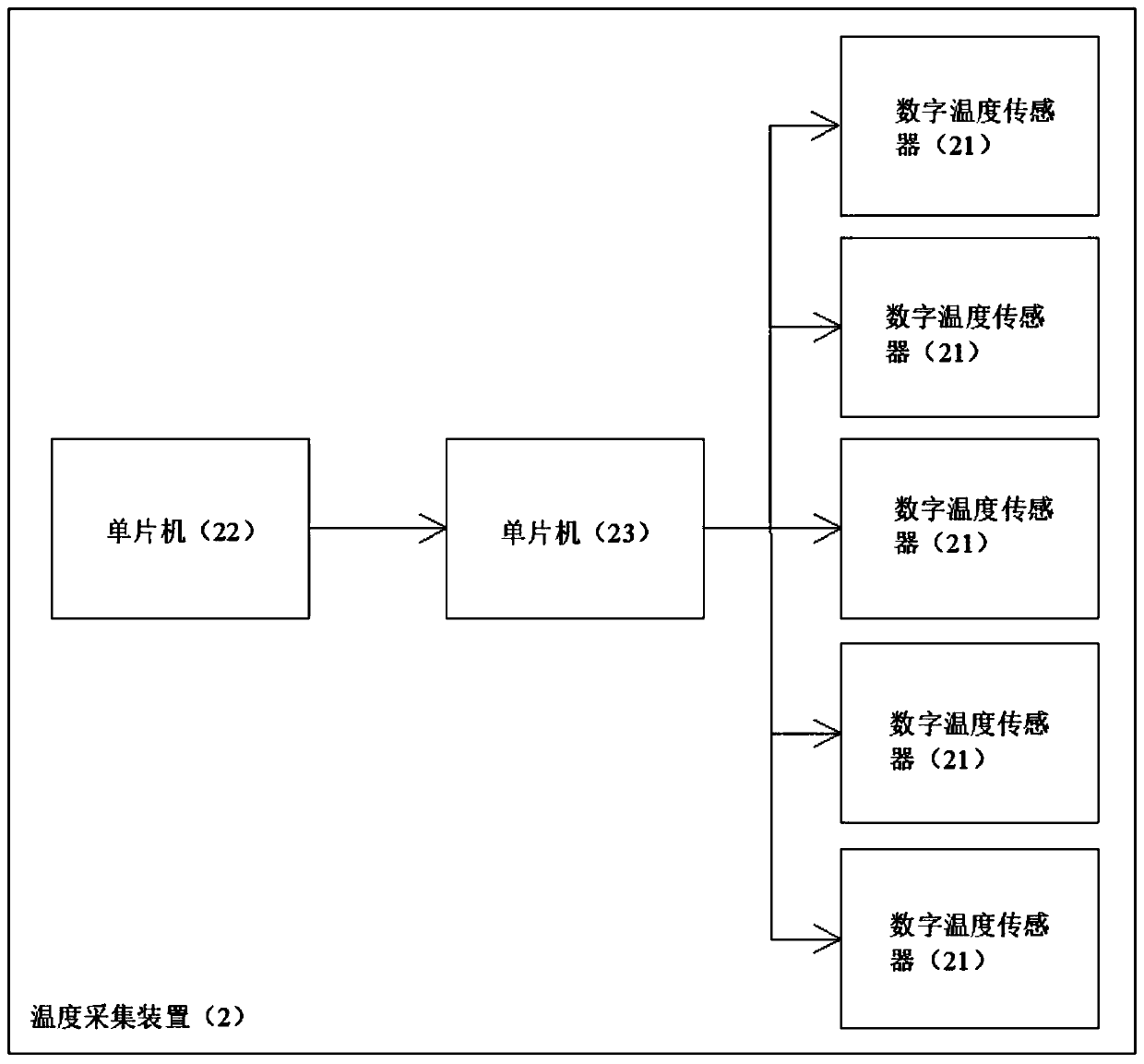

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

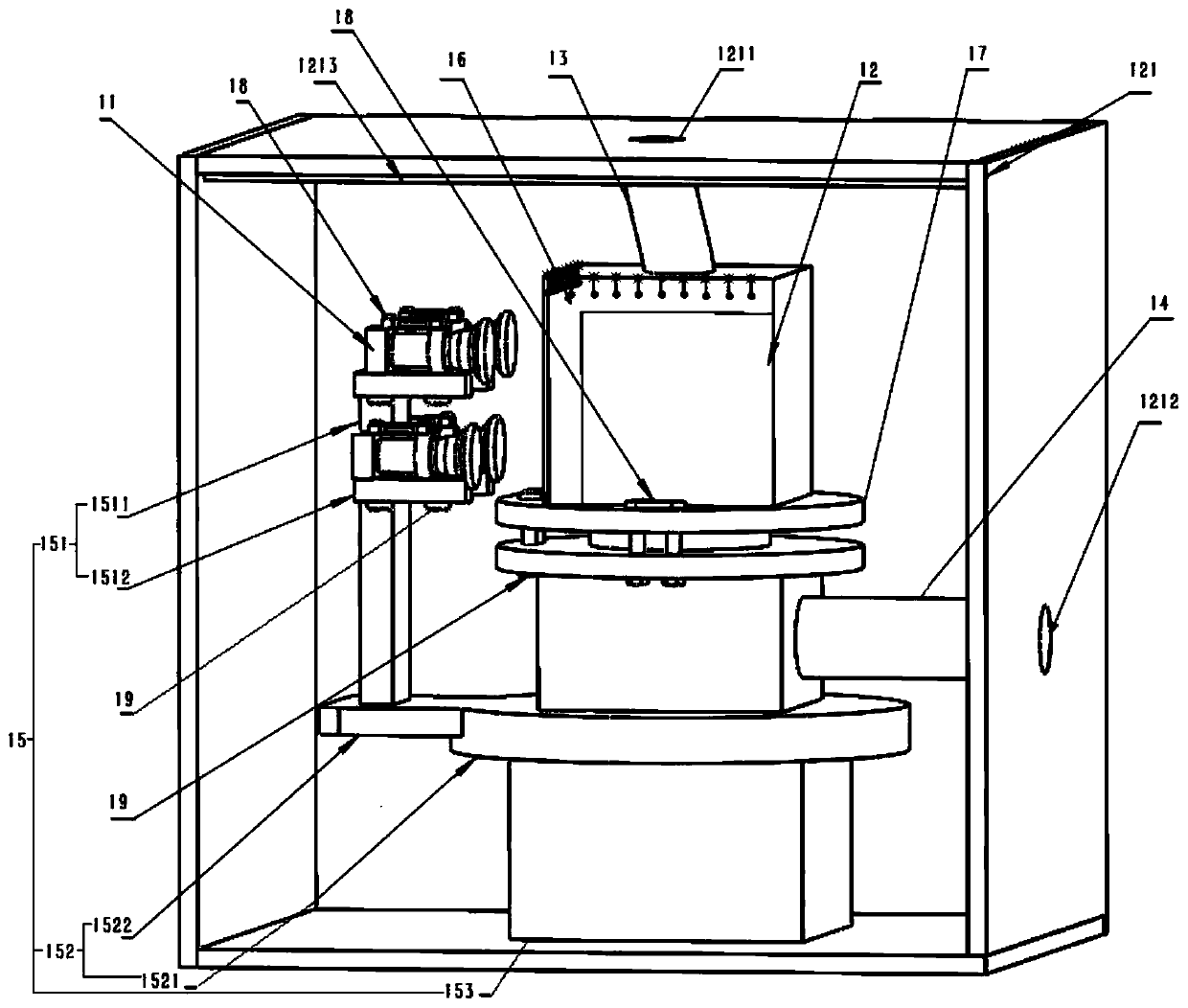

[0057] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention. The fixed connection, fixed arrangement, and fixed structure mentioned in this embodiment are known technologies known to those skilled in the art, such as gluing, welding, screw connection, bolt and nut connection, and riveting.

[0058] In this embodiment, a high-definition industrial-grade CCD camera is used together with a microscope objective lens, and a 20 million-pixel CCD camera can identify dust particles of 10um-500um. The microscopic objective lens is fixedly installed in front of the CCD camera lens. This technology is a known technology and can be directly purchased in the marke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com