Basket welding tool

A technology for welding tooling and baskets, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low production efficiency, high basket deformation rate, and difficulty in taking out the basket, so as to improve production efficiency , Solve the difficulty of taking out and solve the effect of high deformation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

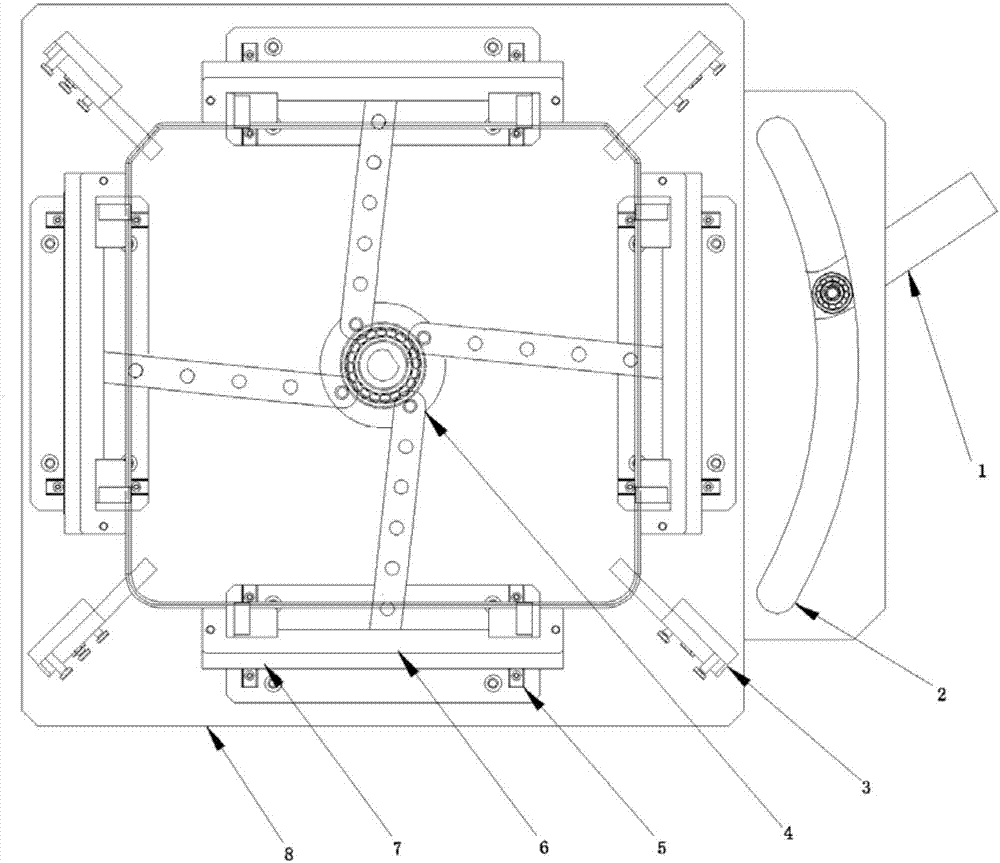

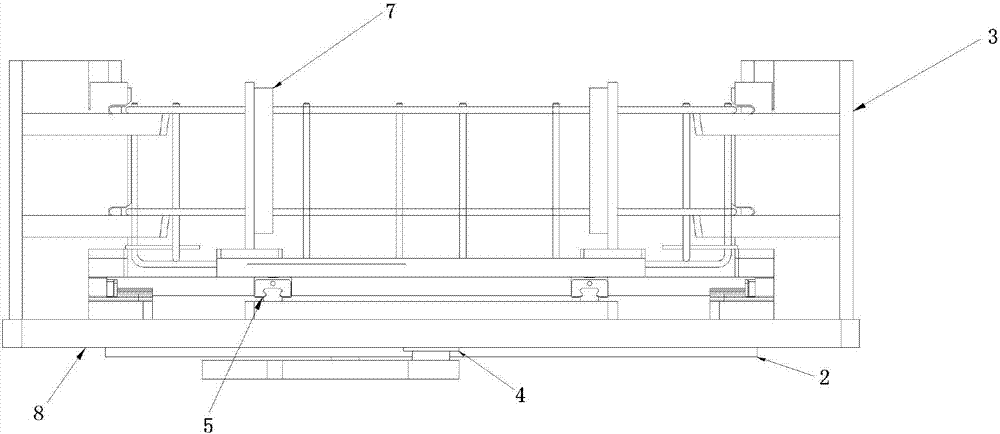

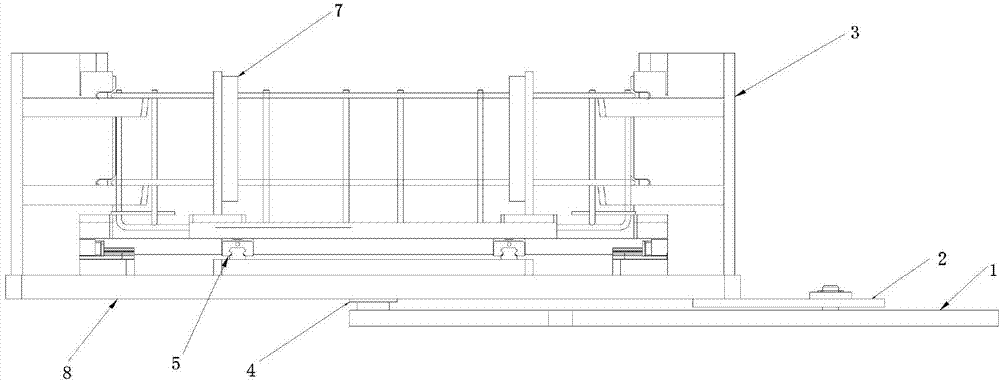

[0013] like Figure 1-3 As shown, the present invention discloses a basket welding tool, including a handle 1, an arc guide rail 2, four product brackets 3, a rotating shaft disk 4, four linear slide rails 5, four connecting rods 6, four Fixing seat 7 and base 8: the base 8 is a cuboid, four brackets for products 3 are respectively fixed on the four corners of the base 8, the arc guide rail 2 is fixed on one side of the base 8, the handle 1 is on the same side as the arc guide rail 2 and There is a positioning device on the handle that is limited to movement in the arc guide rail 2. Turning the handle 1 drives the rotating shaft disc 4 to rotate, so that the connecting rod 6 that one end is connected to the quarter point of the rotating shaft disc 4 and the other end is connected to the fixed seat 7 rotates. The fixed seat 7 advances ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com