Maintenance member

A component and protective plate technology, applied in printing and other directions, can solve the problem of liquid wetting operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

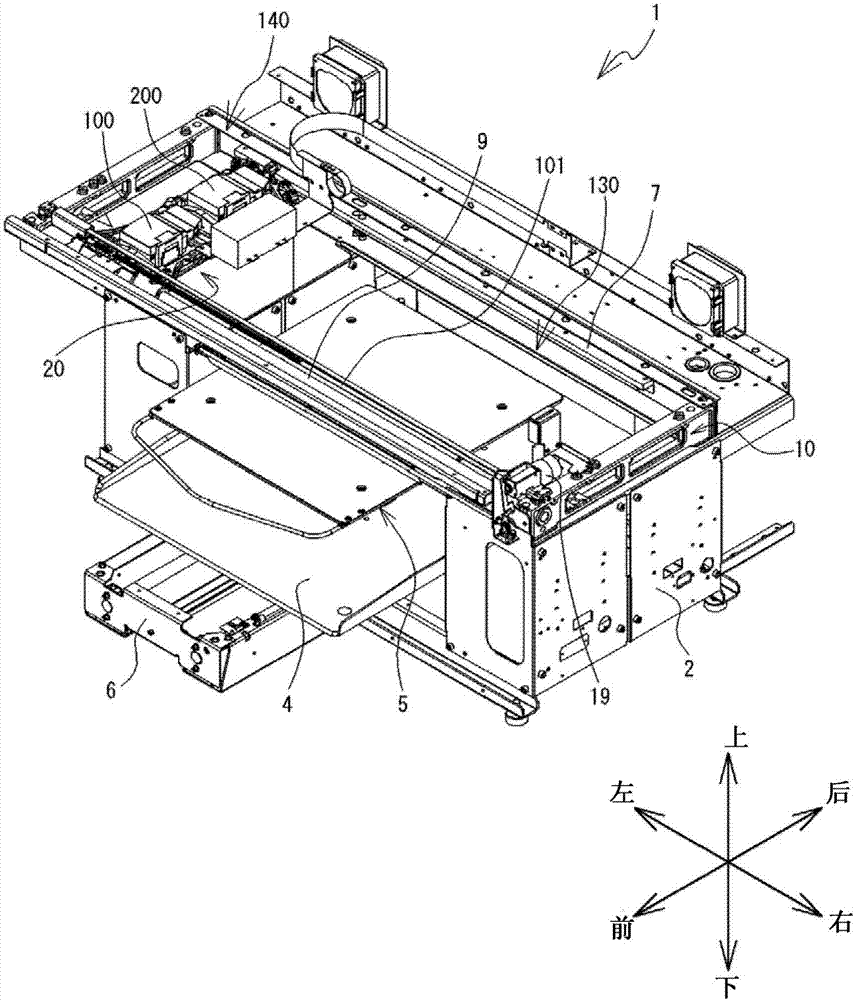

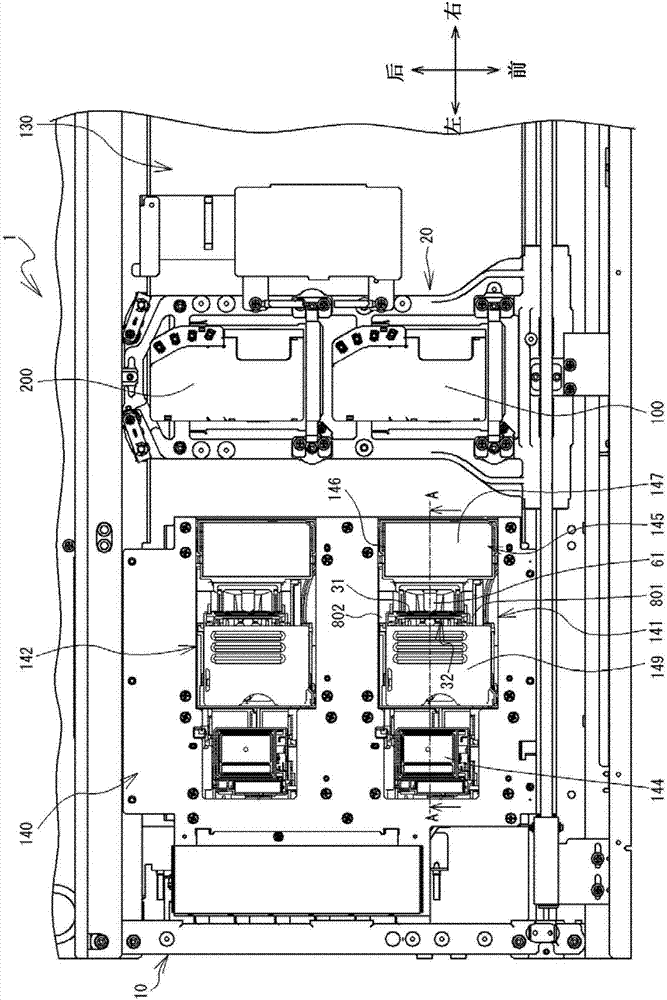

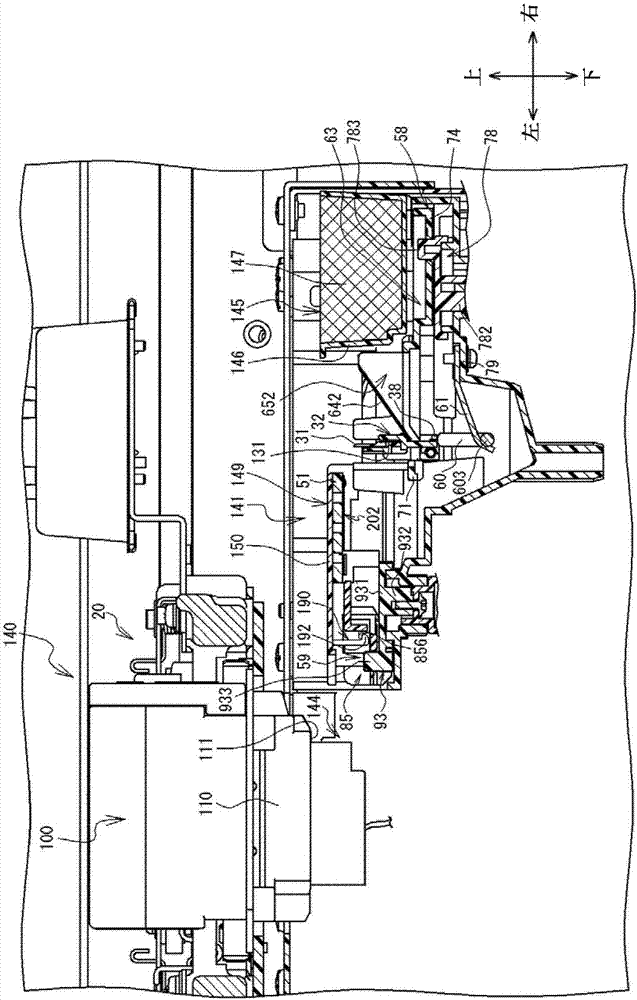

[0042] refer to Figure 1 to Figure 8 , the configuration of the printer 1 will be described. In the following description, left and right, front and rear, and up and down indicated by arrows in the figure are used.

[0043] like figure 1As shown, the printer 1 is an inkjet printer that ejects ink as an example of a liquid onto a fabric (not shown) such as a T-shirt as a printing medium to perform printing. The printing medium may also be paper or the like. The printer 1 is capable of ejecting, for example, five different inks (white, black, yellow, cyan, and magenta) downward to print a color image on a printing medium. In the following description, the white ink among the five inks is called white ink. The four color inks of black, cyan, yellow, and magenta are collectively referred to as color inks.

[0044] The printer 1 includes a housing 2, a platen driving mechanism 6, a pair of guide rails (not shown), a platen 5, a tray 4, a frame 10, a shaft 9, a rail 7, a carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com