Low-temperature pipe clamp

A pipe clamp, low temperature technology, applied in the direction of pipeline supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve problems such as increasing the labor cost of replacement operations, affecting the effect of pipe clamps to fix the pipeline, and increasing the cost of replacing new pipe clamps. , to achieve the effect of fast and efficient installation, shortened installation time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

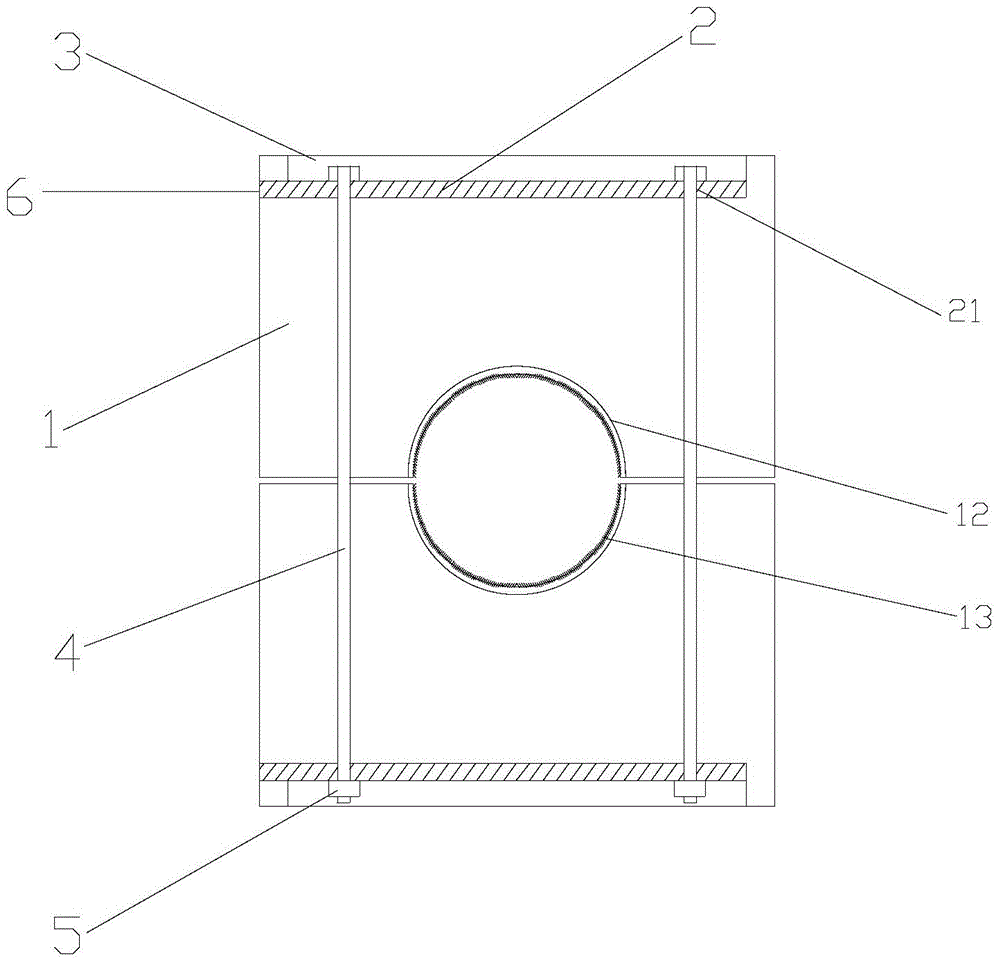

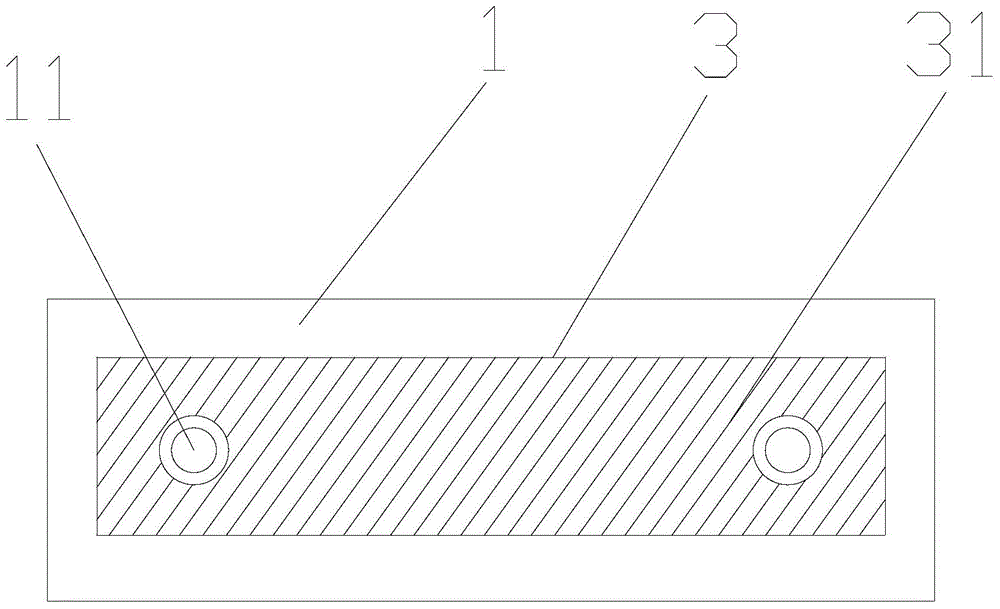

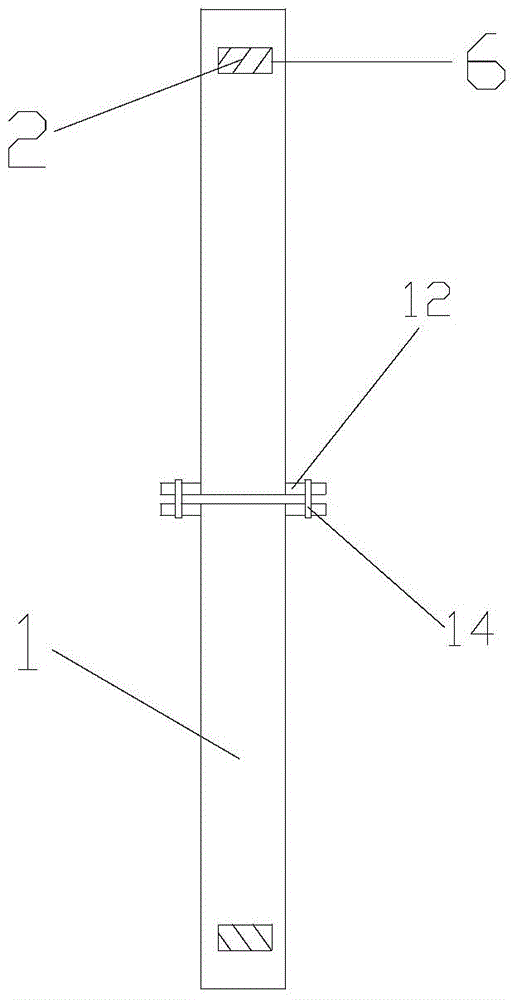

[0024] Below in conjunction with accompanying drawing of description, the present invention will be further described.

[0025] Such as figure 1 , figure 2 and image 3 as shown,

[0026] A low-temperature pipe clamp, comprising a pipe clamp body with a central through hole, the size of the central through hole matches the size of the delivery pipeline, the pipe clamp body includes two half-clamp bodies 1 with the same structure, and the half-clamp bodies One end surface of 1 is the structure of a half central through hole; the other end surface of the half clip body 1 is provided with a groove 3 for assembling the splint 2, and the splint 2 is provided with a fixing hole 21, and the two half clips The clip body 1 is fastened and connected by two bolts 4; The splint fixing hole 21 stretches out from the end of the bolt 4, and the end of the bolt 4 is locked by a nut 5; the inner wall on one side of the groove 3 is provided with a jack 6 for horizontally inserting the spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com