Novel cabin door actuator

A technology for actuators and hatches, applied to aircraft doors, manual mechanisms, door/window accessories, etc., can solve the problems of high cable requirements, low reliability, and effective energy consumption, and achieve good economy, reliability and safety High performance and energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

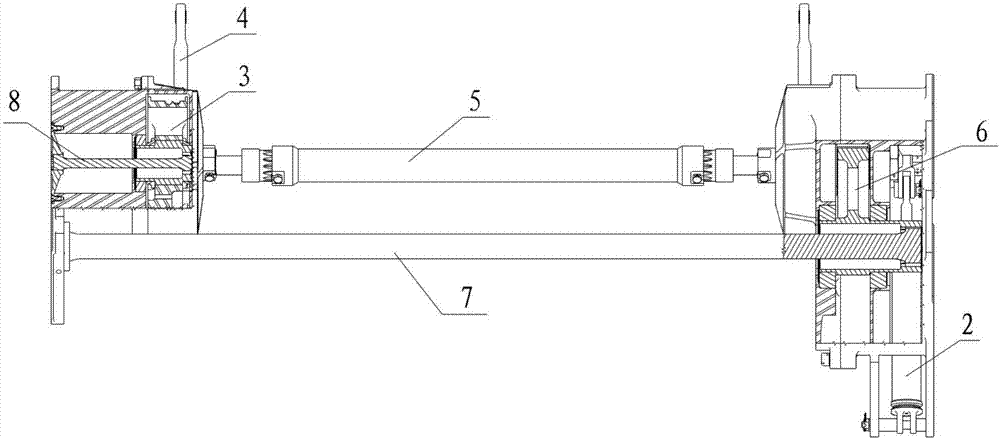

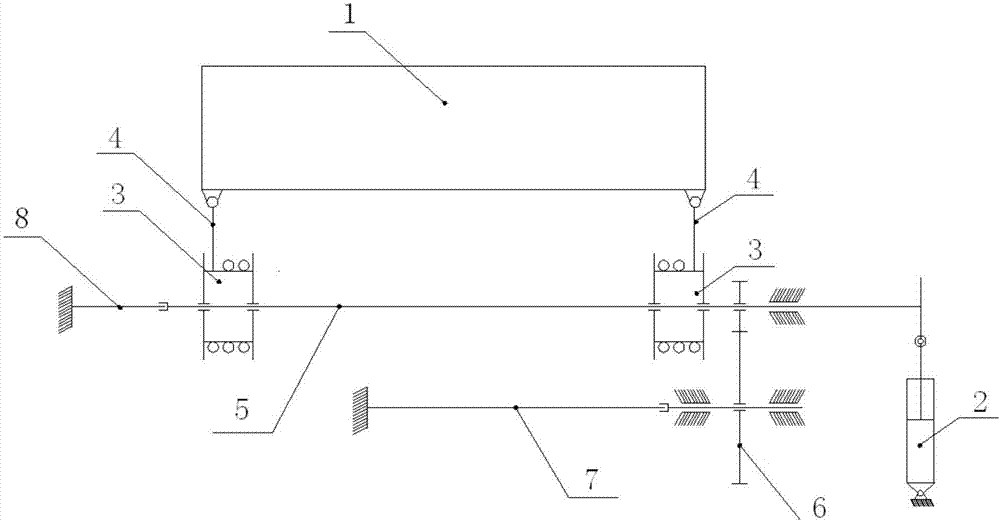

[0017] Referring to the accompanying drawings, a novel hatch actuator is provided, which includes a buffer 2, a cable drum assembly 3, a wire rope 4, a transmission shaft 5, a gear pair 6, a main torsion bar 7 and a balance torsion bar 8;

[0018] The buffer 2 is a one-way actuator;

[0019] A cable drum assembly 3 is fixed on the transmission shaft, and a steel wire rope 4 is wound on the cable drum assembly 3, and one end of the steel wire rope 4 is the connecting end of the cabin door 1, and the other end of the steel wire rope 4 is a fixed end;

[0020] One end of the transmission shaft is provided with a bump, and one end of the balance torsion bar 8 is a sleeve structure, and the inner wall of the sleeve structure is provided with a bump, and the sleeve structure is sleeved on one end of the transmission shaft. The shaft protrusion will be locked with the protrusion of the casing structure, so that the transmission shaft drives the balance torsion bar 8 to twist;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com