Quantitative liquid outlet bottle cover

A technology for bottle caps and liquid bottles, applied in the field of bottle caps, can solve problems such as environmental pollution, difficulty in industrial production, and increased costs, and achieve the effects of reducing costs, avoiding waste of resources and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

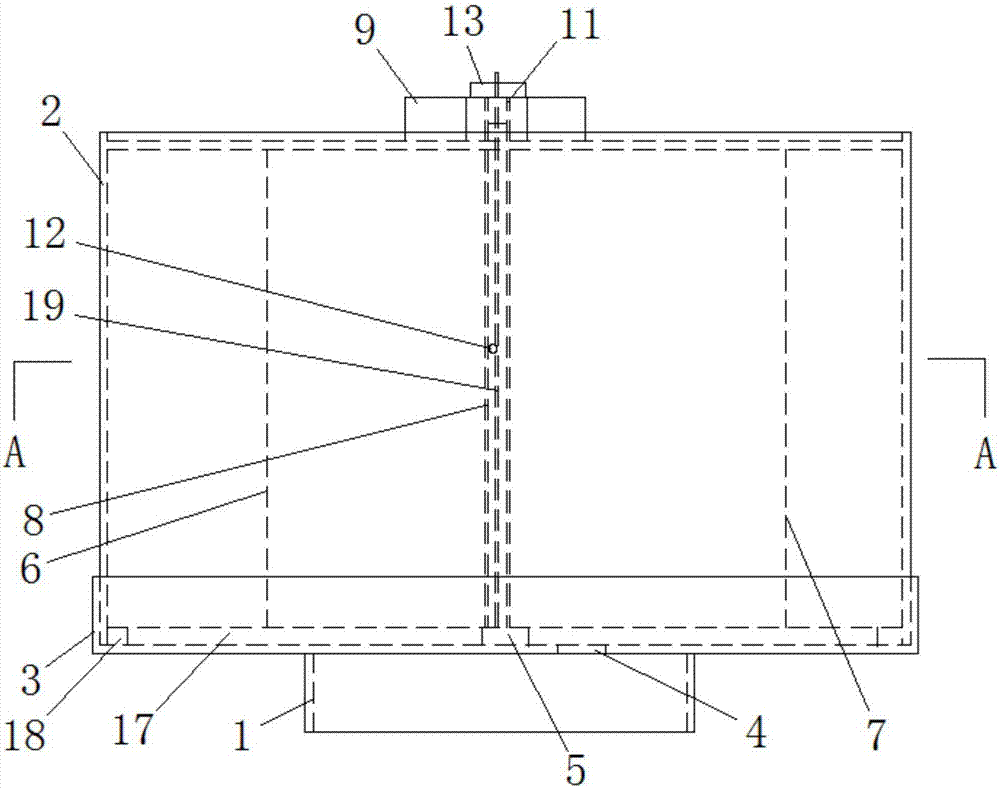

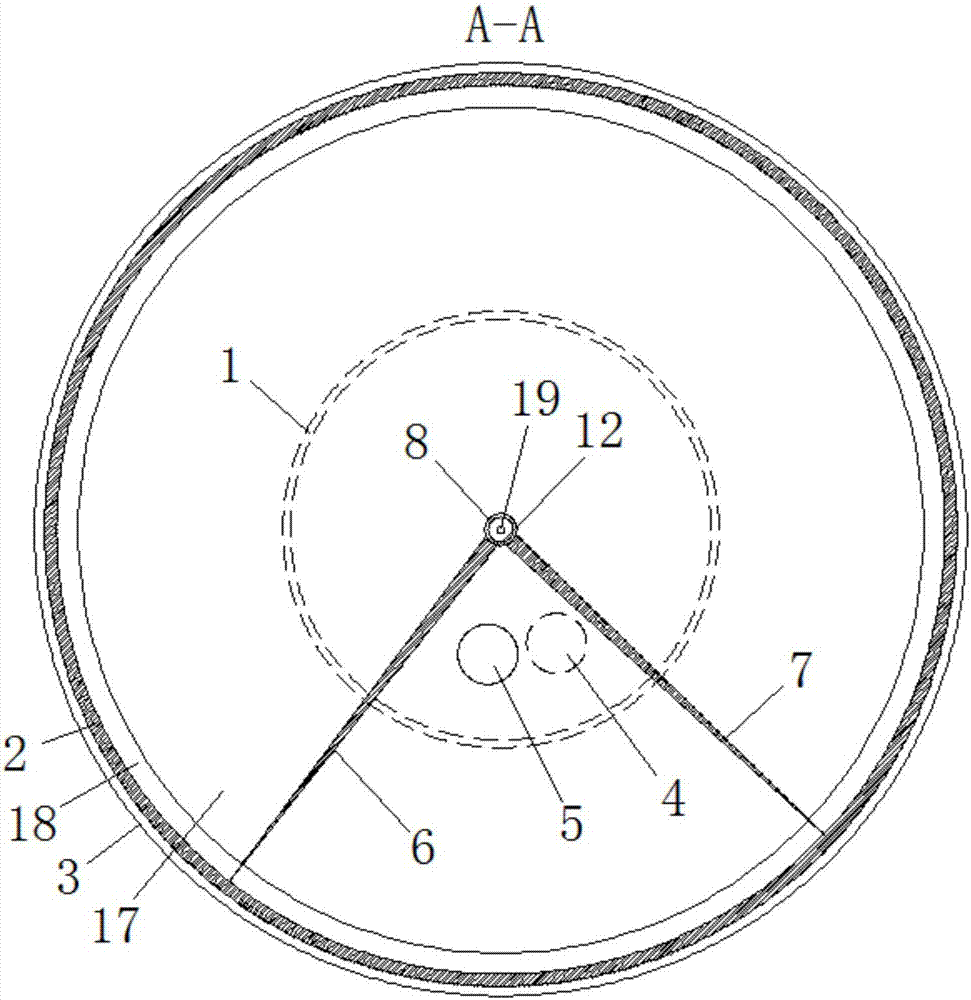

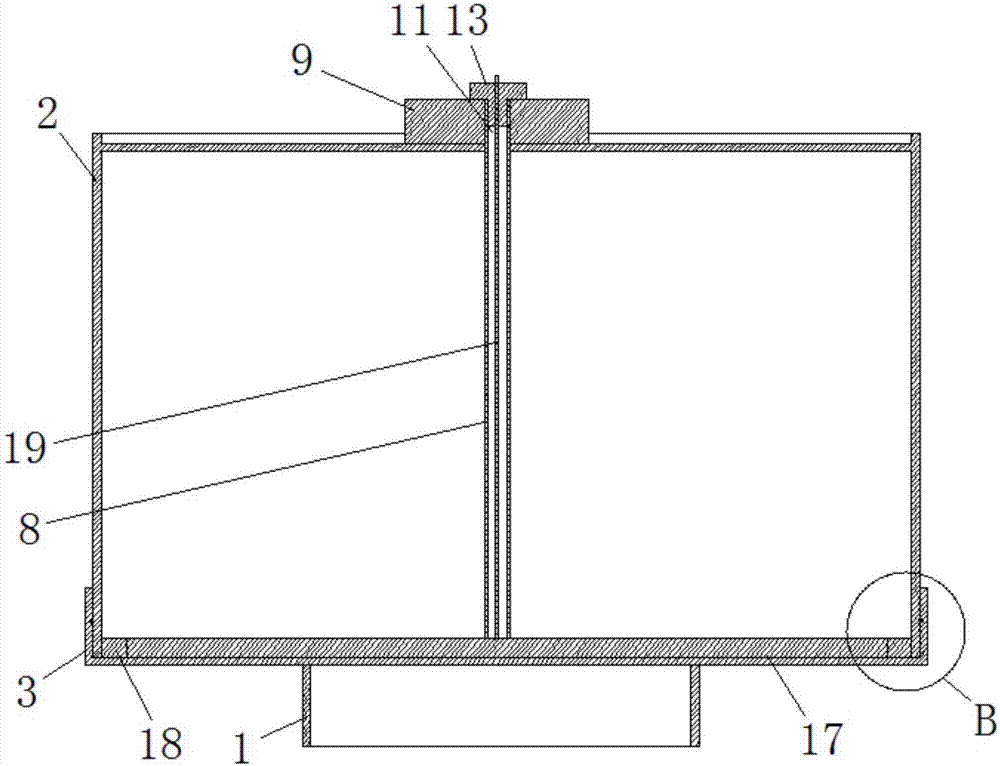

[0019] refer to Figure 1 to Figure 8 , the present embodiment provides a bottle cap for quantitative liquid discharge, including a bottle cap 1 and a cylinder 2, the bottom of the cylinder 2 is an open structure, and the top is a closed structure, and the upper end of the bottle cap 1 is fixedly provided with a connecting cap 3 , the upper end of the bottle cap 1 is rotatably connected to the lower end of the cylinder 2 through the connecting cap 3, the side wall inside the connecting cap 3 is provided with a limiting groove 15 along the circumferential direction, and the corresponding limiting groove is arranged on the outer wall of the cylinder 2 15 is provided with a limit protrusion 16 that matches the limit groove 15, and the rotatable connection between the two can be realized by snapping the limit protrusion 16 into the limit groove 15. The bottle cap 1 and the connection The cap 3 is provided with a liquid outlet 4 that passes through the upper end of the bottle cap 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com