Motor-controlled automatic walking and unreeling and tipping prevention wire roller for electricity

A motor control and self-propelled technology, applied in the field of online rollers, can solve the problems of increasing pay-off time, reducing work efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

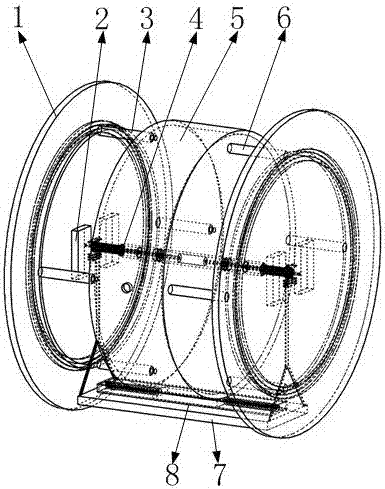

[0035] please see Figure 1 to Figure 16 . Such as figure 1 , 2 As shown, it includes an adjustment mechanism 4, a traveling mechanism 43, a trigger mechanism 8, such as figure 1 , 2 As shown, wherein the regulating mechanism 4 and the triggering mechanism 8 are all installed on the traveling mechanism 43 .

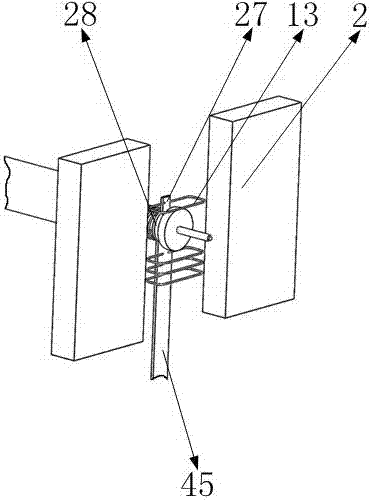

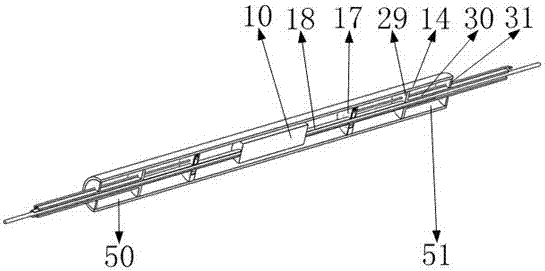

[0036] Such as figure 1 , 2 As shown, the above-mentioned traveling mechanism 43 includes a wire wheel 1, a generator magnet 2, a scroll spring 46, a telescopic rod 3, a support column 6, a T-ring 9, a motor 10, a T-ring 9 slots, a hollow sleeve 18, a battery 7, Drive ladder shaft 23, battery 7 fixed plates, magnet ring 24, fixed bar 25, coil 13, coil 13 fixed plates, fixed circular plate 28, as figure 1 , 2 Shown, wherein the two ends of motor 10 all have motor 10 axles; As figure 1 , 2 As shown, the two hollow sleeves 18 are all nested on the outer surface of the motor 10 shaft and the two hollow sleeves 18 are symmetrically installed on the two ends of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com