Rapid transferring device for piled bricks

A technology of handling device and brick stack, applied in the field of brick stack rapid handling device, can solve problems such as slow brick stack handling, and achieve the effects of saving labor, reducing production cost and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

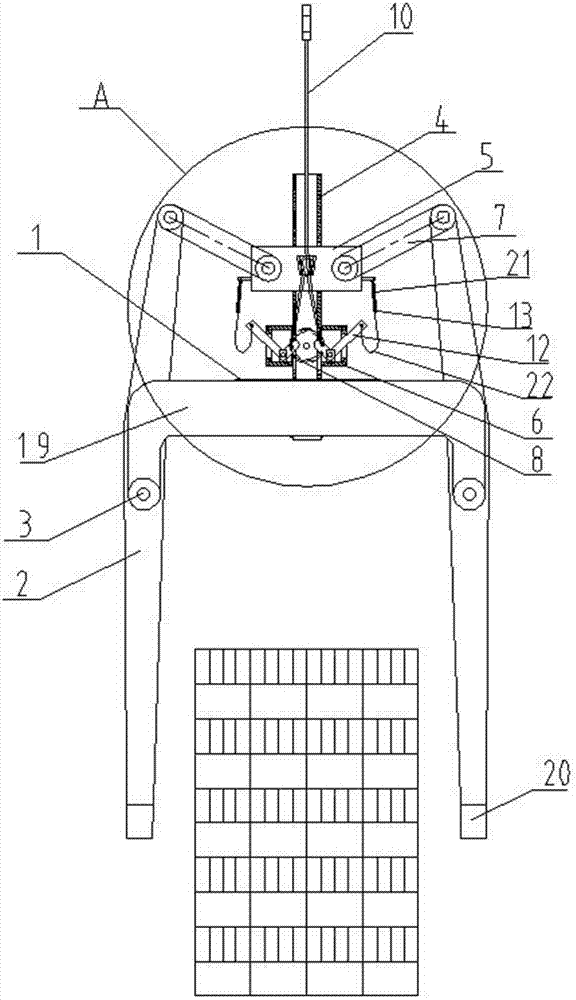

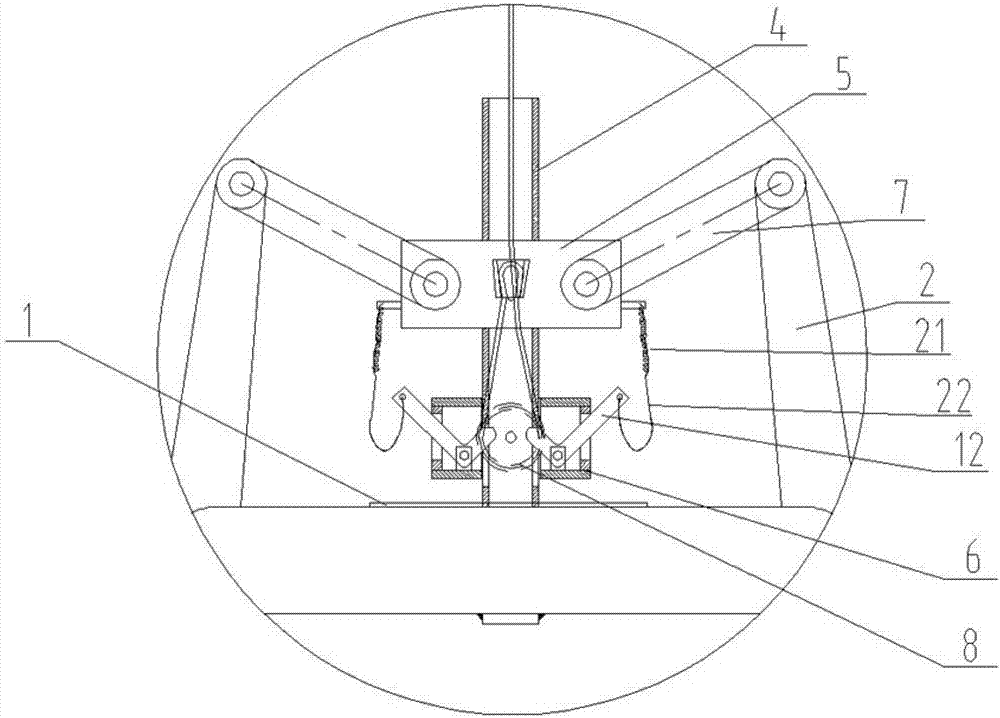

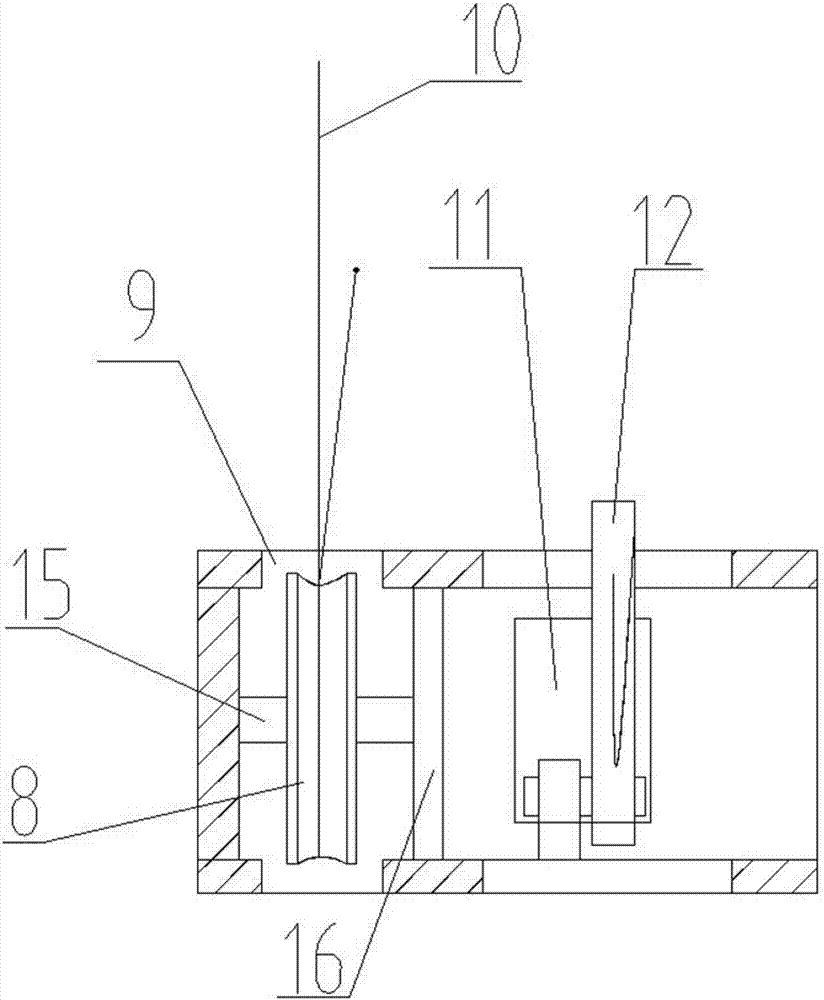

[0019] The present invention will be further described below in conjunction with accompanying drawing.

[0020] Such as Figure 1-Figure 5 As shown, a kind of fast handling device for brick stacks includes an installation platform 1, two grasping arms 2 are symmetrically installed on both ends of the left side of the installation platform 1, and two grasping arms 2 are symmetrically installed on the two ends of the right side of the installation platform 1. One grabbing arm 2, the middle part of four grabbing arms 2 are respectively hinged on the installation platform 1 through the pin shaft 3, and the axial direction of the pin shaft 3 is arranged perpendicular to the left side of the installation platform, so that the grabbing arms can be wound around the pin shaft Rotate to realize the clamping function. A vertically arranged slide bar 4 is fixed in the center of the installation platform 1. A connecting block 5 and a box-type slide block 6 are sequentially installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com