Tool anchor used for dismantling unbonded prestressed concrete structure and using method thereof

A concrete structure, non-bonded technology, applied in the direction of structural elements, building components, building structures, etc., can solve the problems of casualties and property losses without bonded tendons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

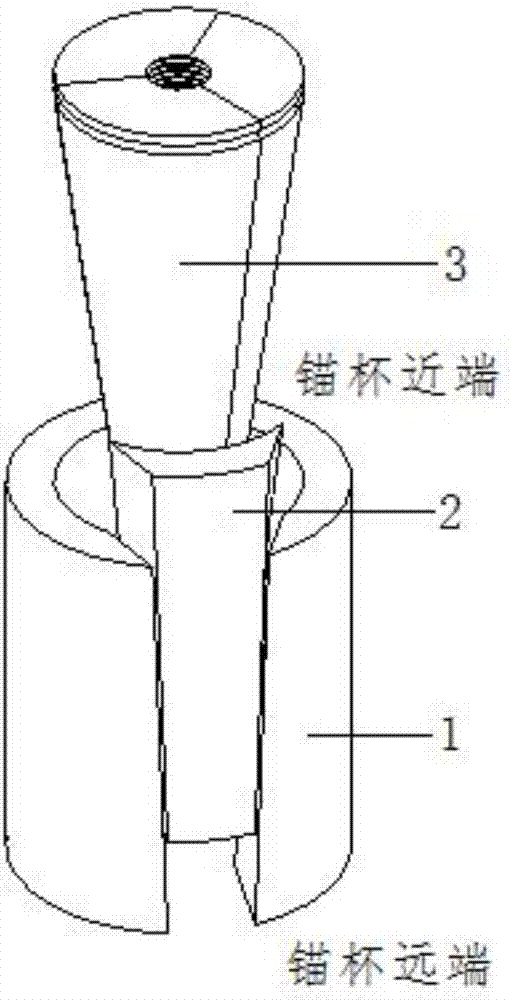

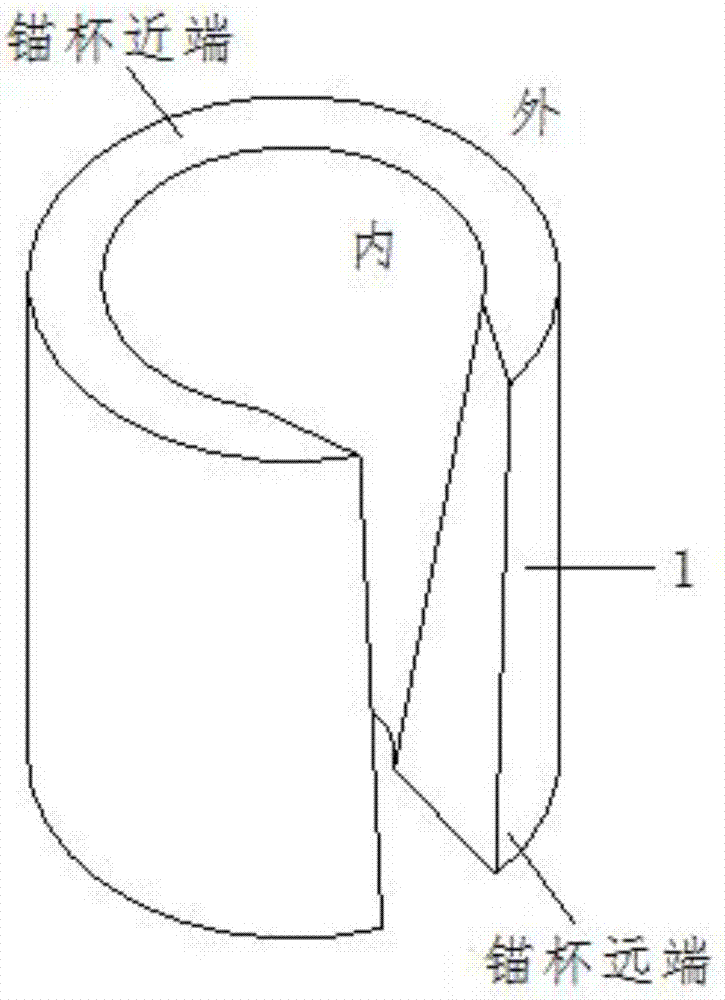

[0017] Specific implementation mode one: combine Figure 1-7 Describe this embodiment in detail. In this embodiment, a tool anchor for removing unbonded prestressed concrete structures is composed of three parts: an anchor cup 1 with a special-shaped notch, a special-shaped plug 2 , and a supporting clip 3 .

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment differs from Embodiment 1 in that the anchor cup 1 with a special-shaped notch is provided with the same central taper hole as the conventional scale anchorage, and the cup wall is wide inside and narrow outside, near wide and far narrow The minimum width of the notch is not less than the nominal diameter of the non-adhesive rib. Others are the same as the first embodiment.

[0019] The inner width and outer narrowness, near width and far narrowness mean that the width inside the upper end of the special-shaped notch is greater than the width outside the upper end of the special-shaped notch; the width inside the lower end of the special-shaped notch is greater than the width outside the lower end of the special-shaped notch; The width of the inner side of the lower end; the width of the outer side of the upper end of the special-shaped notch is greater than the width of the lower end of the special-shaped notch.

specific Embodiment approach 3

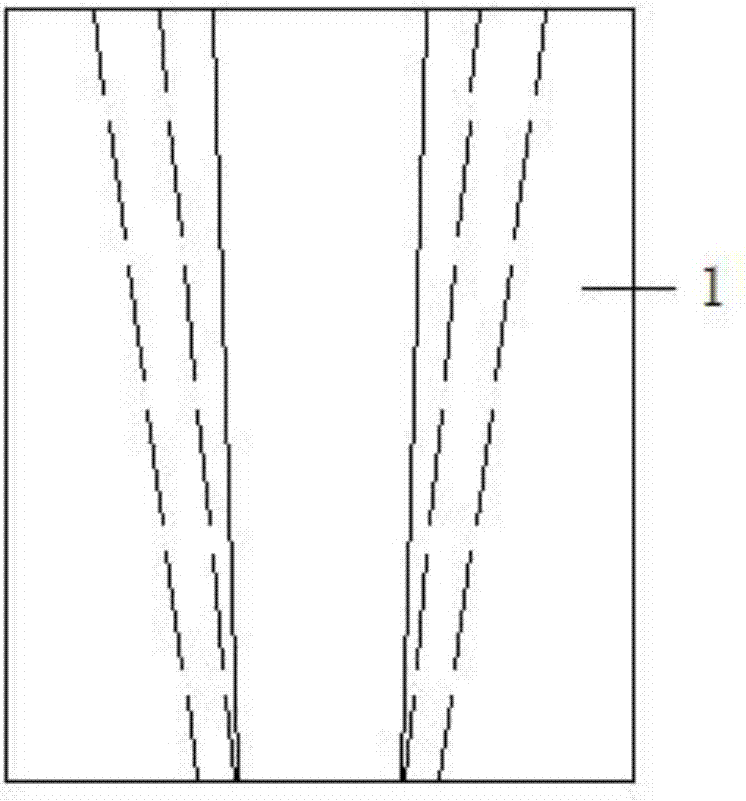

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the shape and size of the special-shaped plug 2 coincides with the shape and size of the anchor cup 1 with a special-shaped notch, which is wide inside and narrow outside, and narrow near and far. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com