Patents

Literature

58results about How to "Won't fly out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

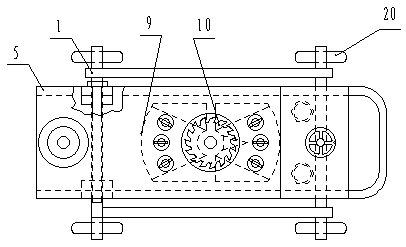

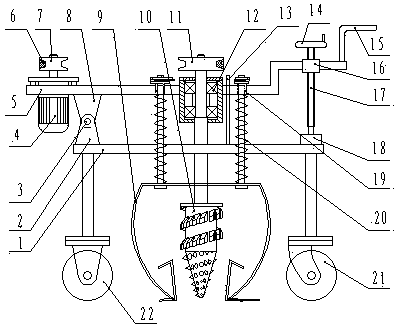

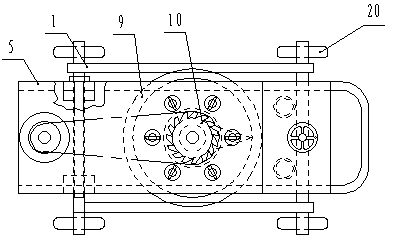

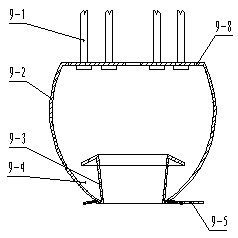

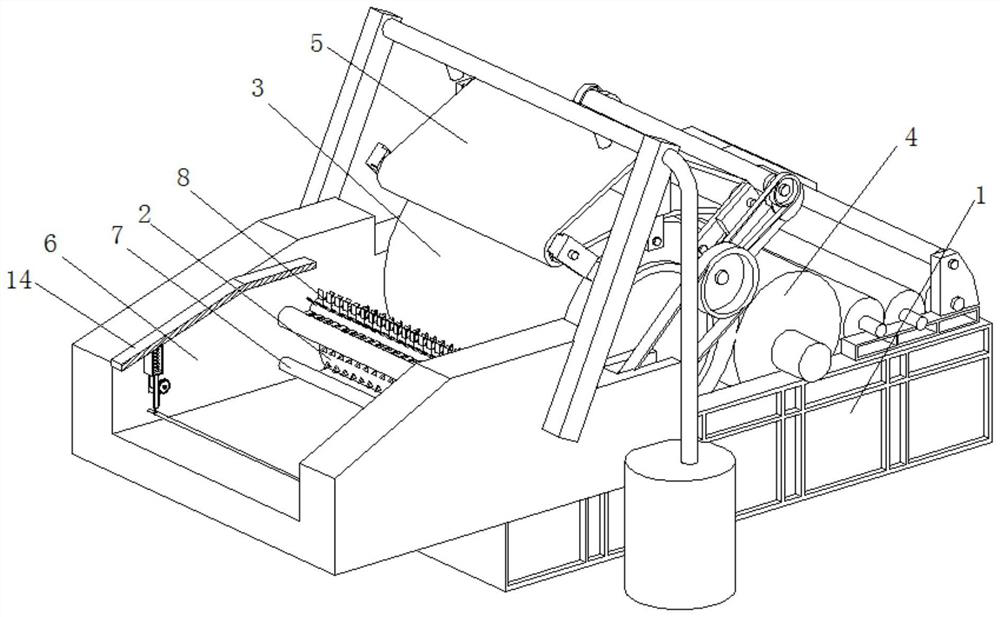

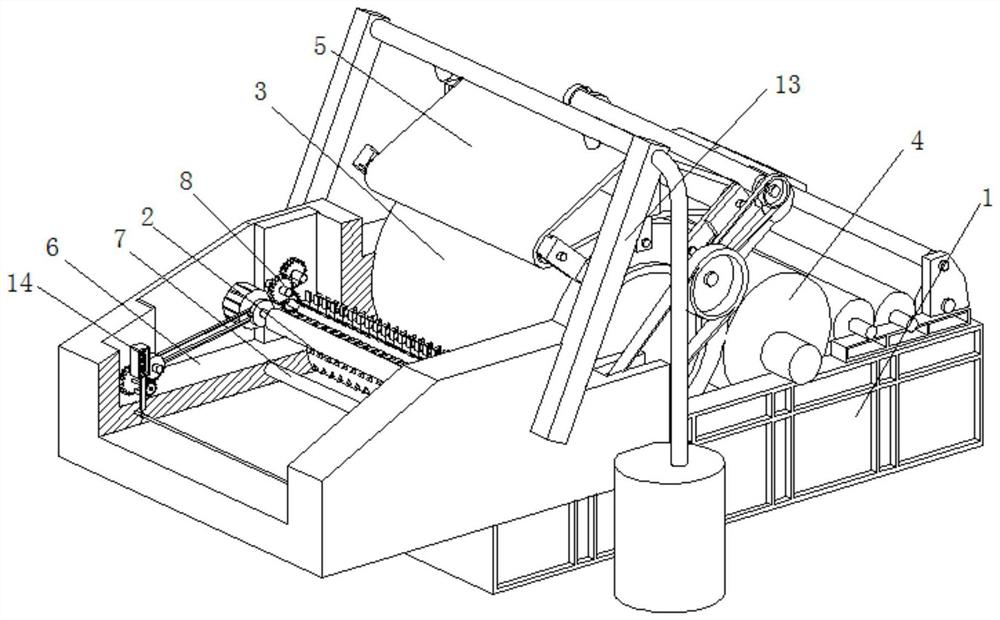

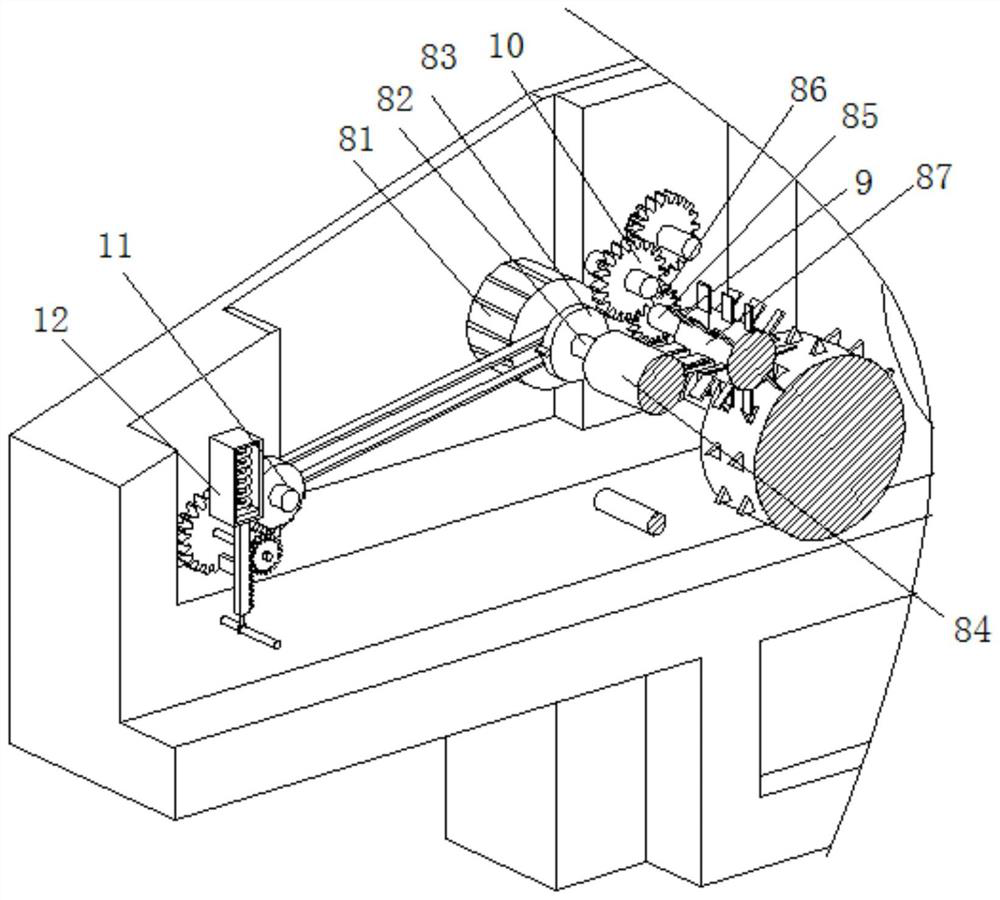

Automatic cleaning pulverizer special for preparing shell powder serving as building decorative material

InactiveCN107497765ANo manual operationShort time consumptionCleaning using toolsCleaning using liquidsEngineeringPulverizer

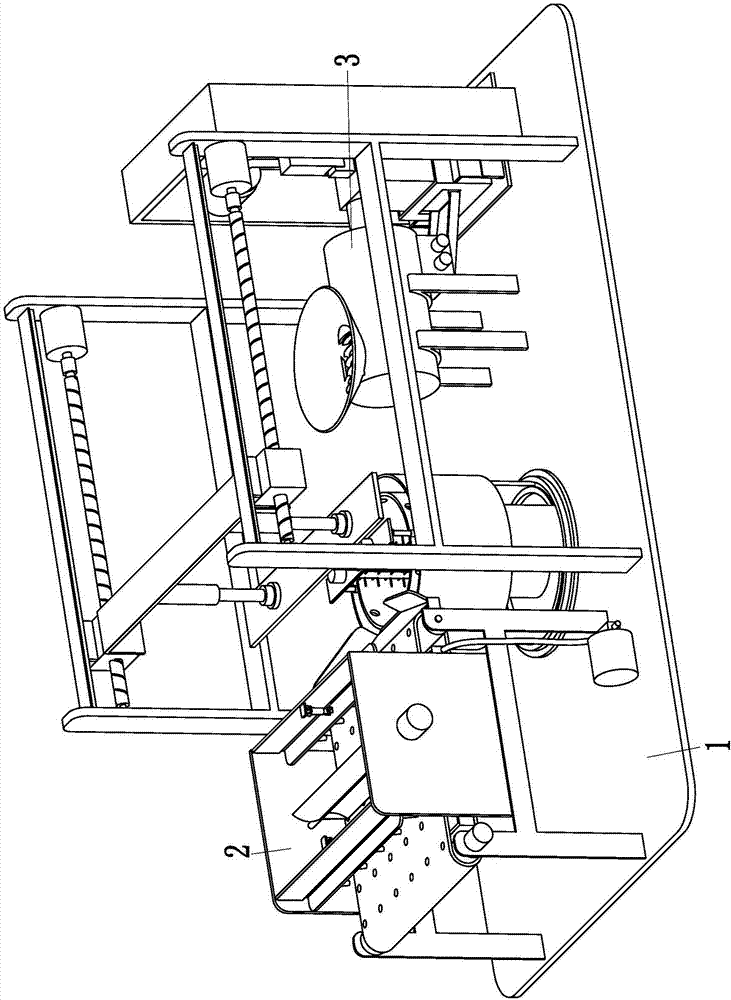

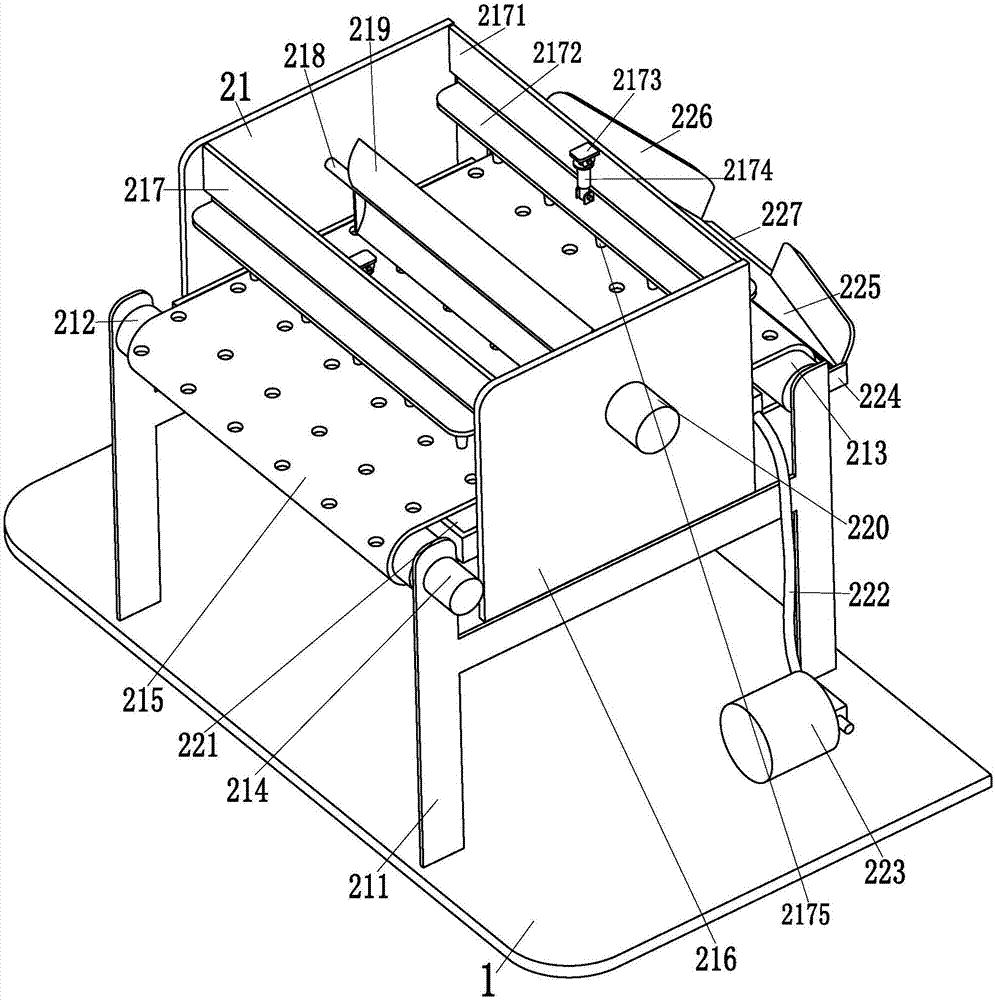

The invention relates to an automatic cleaning pulverizer special for preparing shell powder serving as a building decorative material. The automatic cleaning pulverizer comprises a bottom plate, a cleaning device and a pulverizing device. The cleaning device is installed at the front end of the bottom plate, and the pulverizing device is installed at the rear end of the bottom plate. Through the automatic cleaning pulverizer, the problems that in the existing shell cleaning and pulverizing processes, workers need to clean shells at first and then crush and pulverize the shells into powder with the help of tools, in the cleaning process, due to the fact that dirt on the shells is difficult to remove, the workers need to clean the shells through the tools for a long time, it is difficult to clean up the shells thoroughly, during shell cleaning, the workers need to put the cleaned shells into a frame one by one and then transport the shells to a designated place, the process is tedious and complex, when the workers pulverize the shells into powder with the help of the tools, the shells are prone to flying out after being stressed, pulverized powder particles are uneven in size because that force is unevenly applied to the shells during pulverizing, the labor intensity is high, and the efficiency is low are solved, and the function of automatically cleaning and pulverizing the shells can be achieved.

Owner:王莎莎

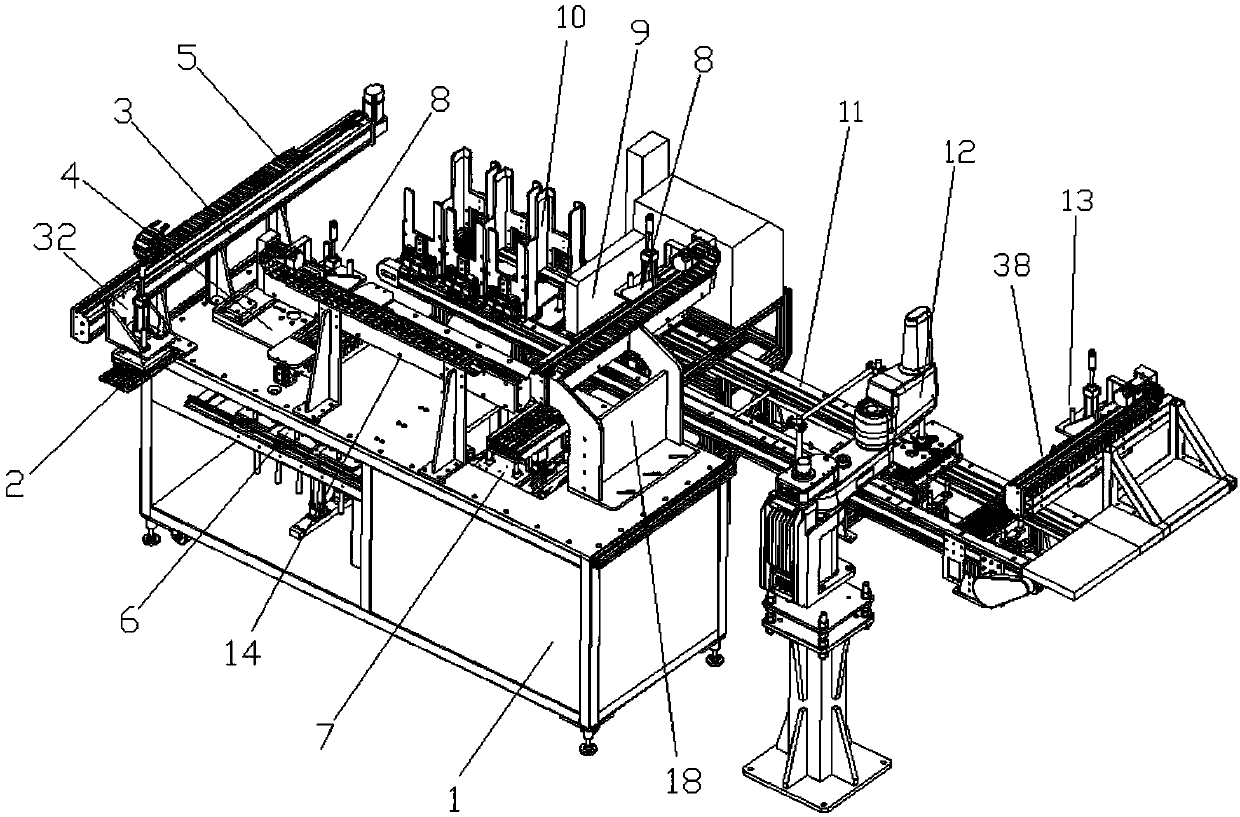

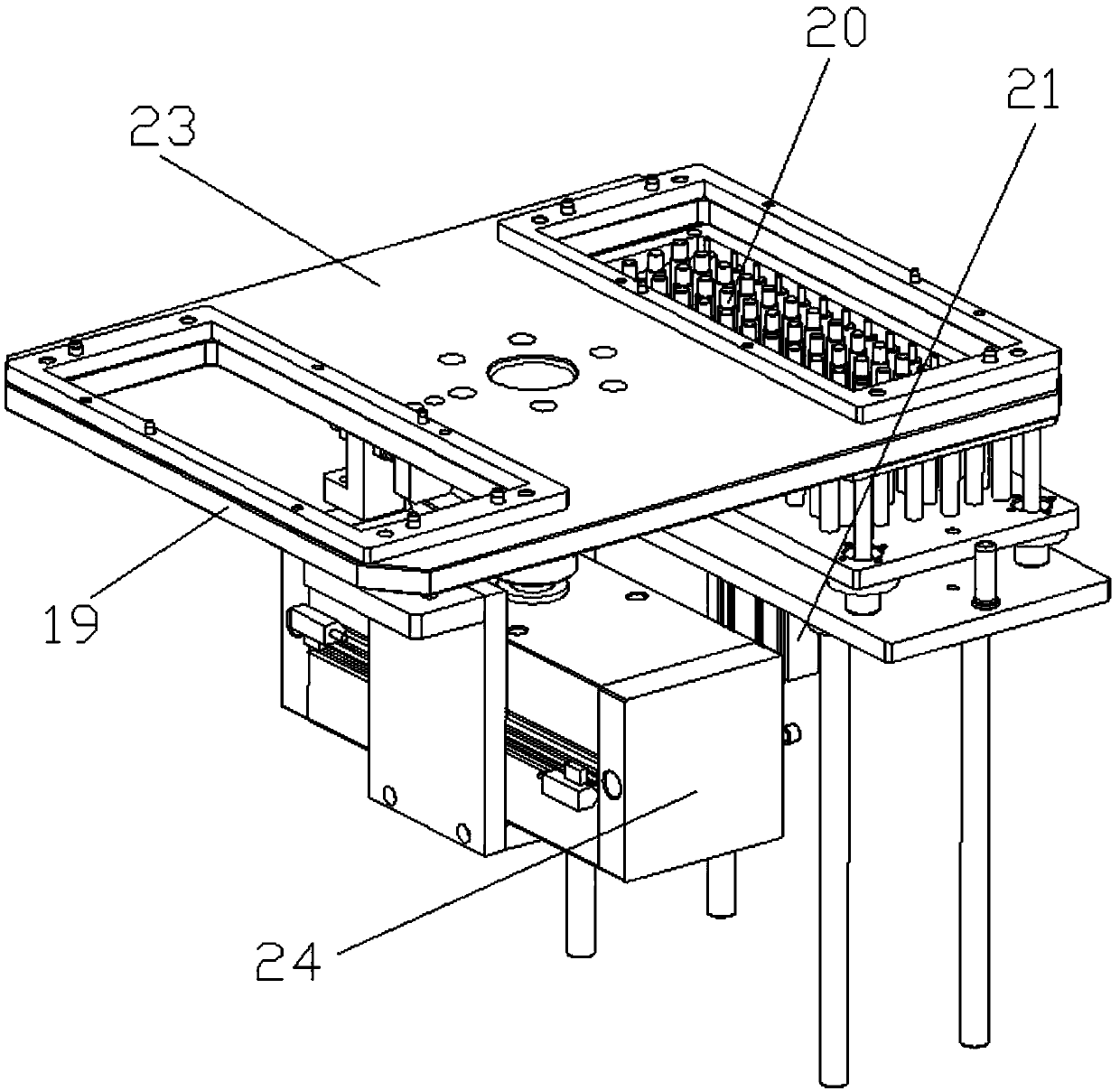

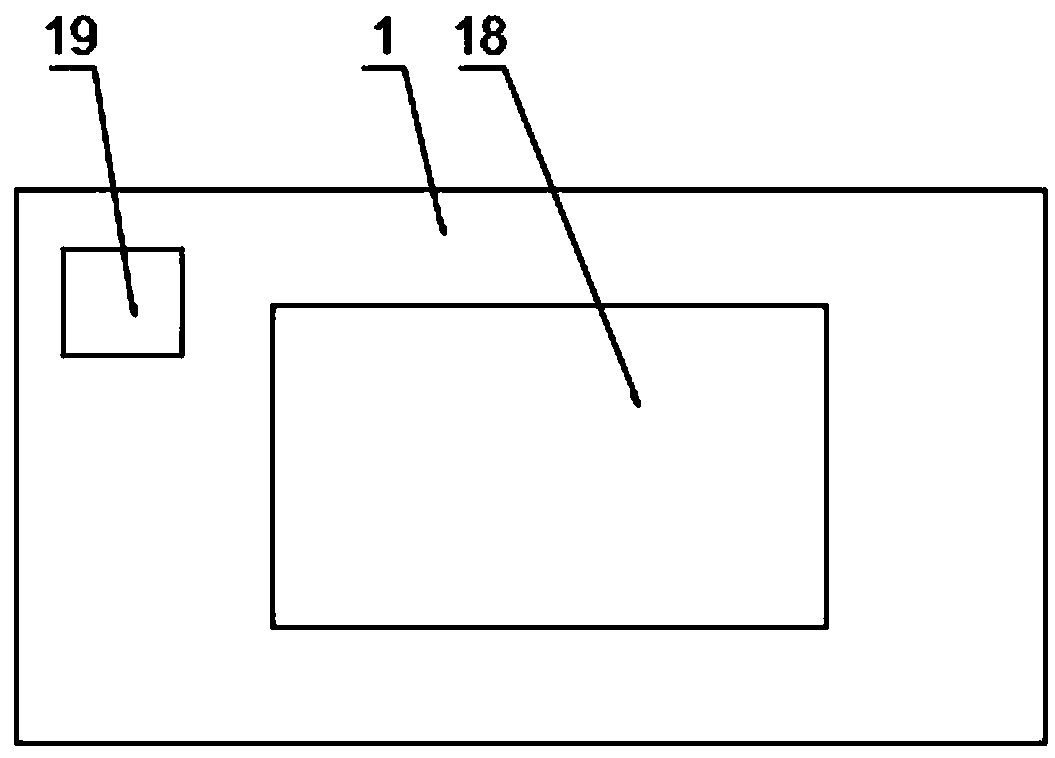

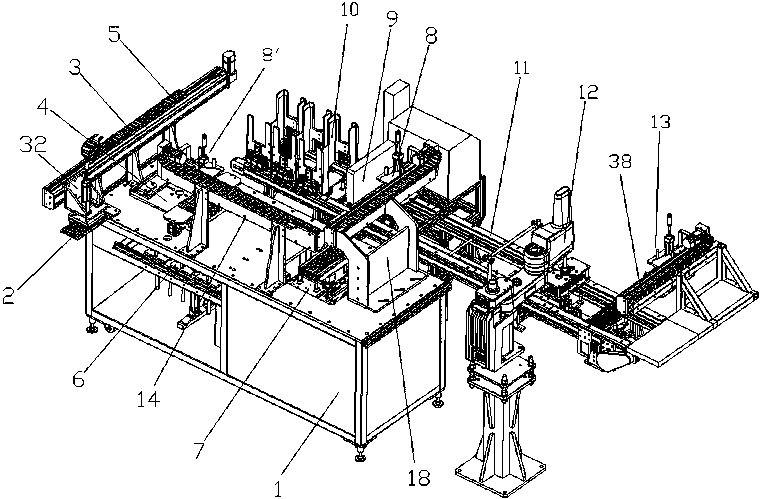

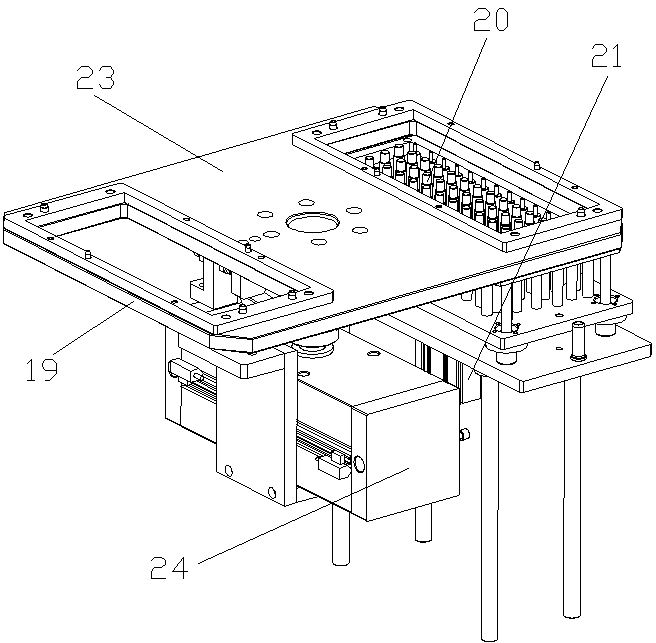

Full-automatic keyboard disassembling and cleaning machine

ActiveCN107737774ARealize fully automatic disassemblyImprove processing efficiencyCleaning using gasesSortingEngineeringManipulator

The invention discloses a full-automatic keyboard disassembling and cleaning machine. The machine comprises a control box, wherein a feeding device, a rotating disc device and a keycap detaching device and a keycap falling device are arranged on the table surface of the control box in sequence from one end to the other end; the feeding device comprises a feeding manipulator arranged on a first electric guide rail; a second electric guide rail is arranged between the keycap detaching device and the keycap falling device; a movable conveying manipulator is arranged on the second electric guide rail; an optical detector is arranged at the rear end of the control box; a third electric guide rail is arranged between the optical detector and the keycap falling device; the conveying manipulator is further arranged on the third electric guide rail; a conveyor belt is arranged below the optical detector; a stacking device is arranged at one end of the conveyor belt, and a dust collecting deviceand a discharging device are arranged at the other end; the discharging device comprises a fourth electric guide rail arranged above the conveyor belt; and a discharging manipulator is arranged on the fourth electric guide rail. The full-automatic keyboard disassembling and cleaning machine can realize full-automatic disassembling, cleaning and sorting of keyboards, thereby being high in automation degree and processing efficiency.

Owner:平邑县经发企业服务有限公司

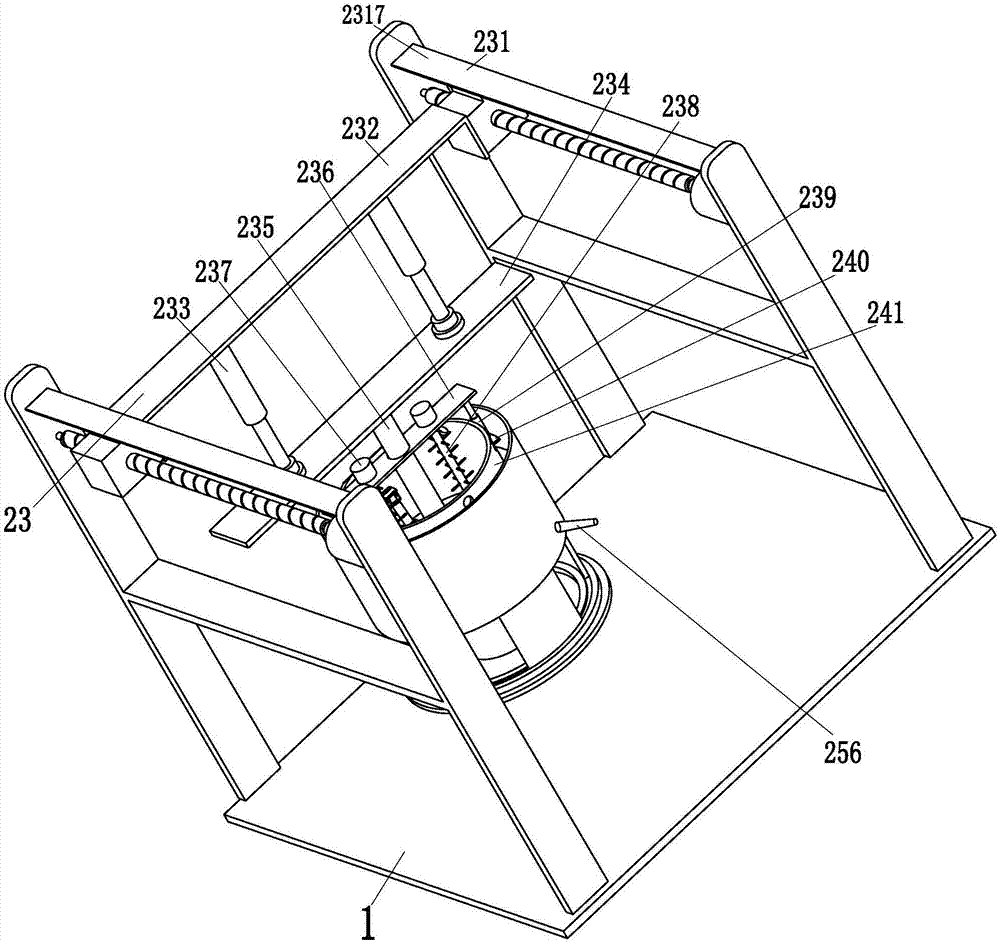

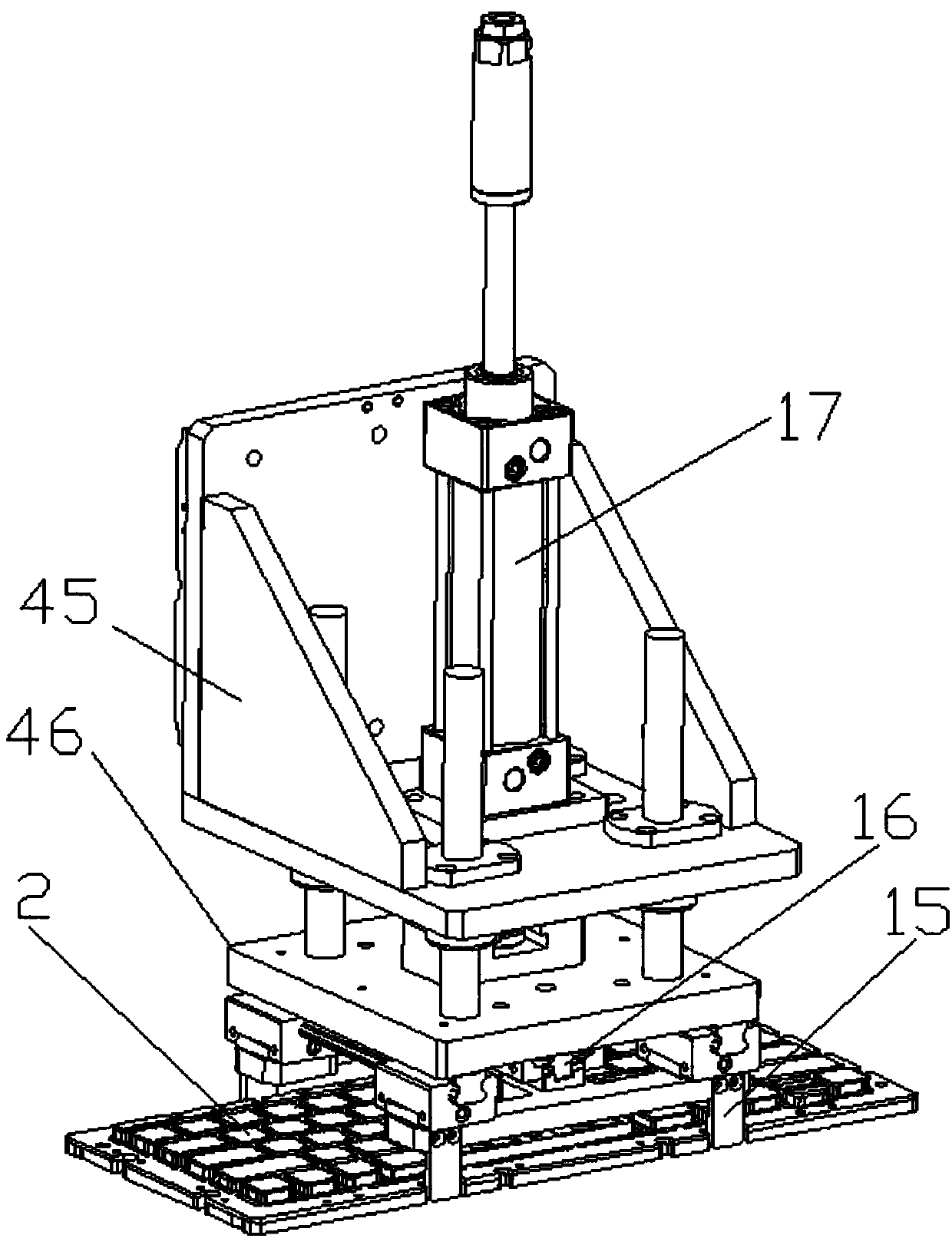

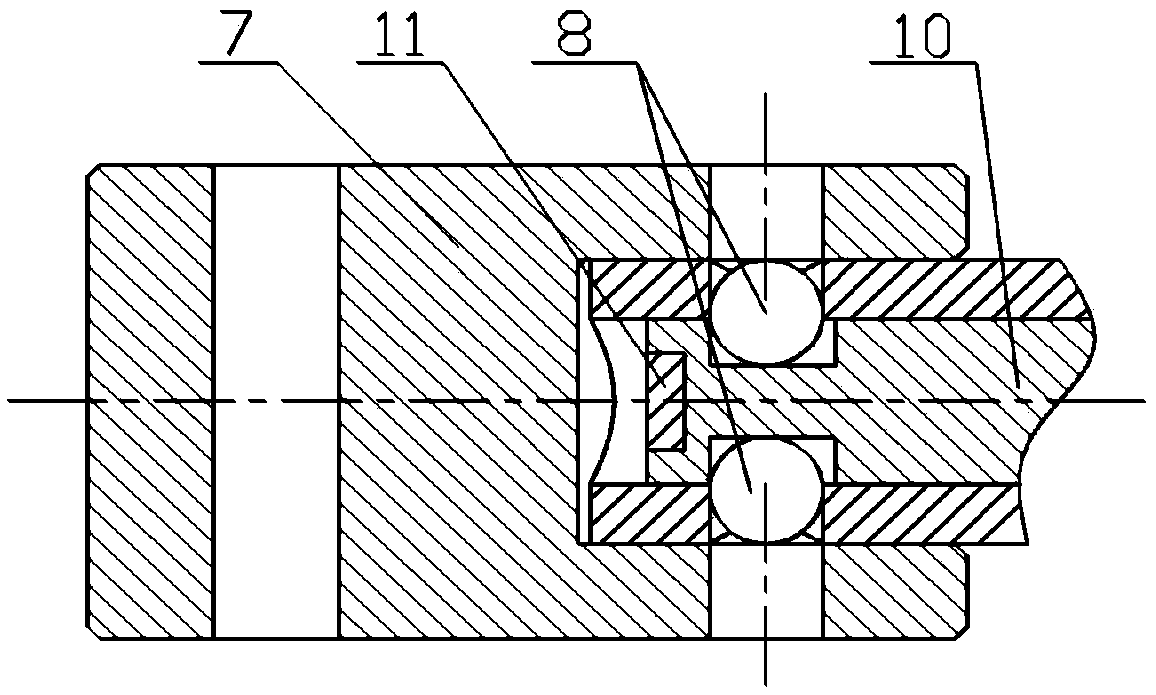

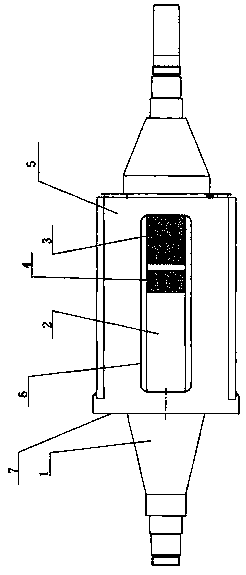

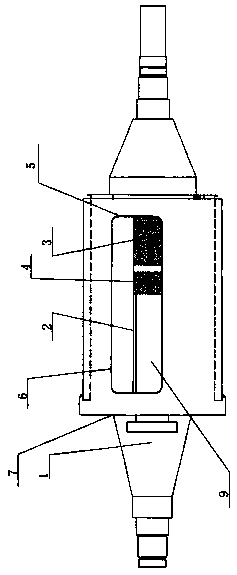

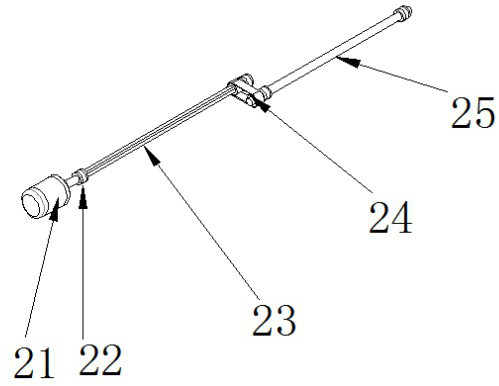

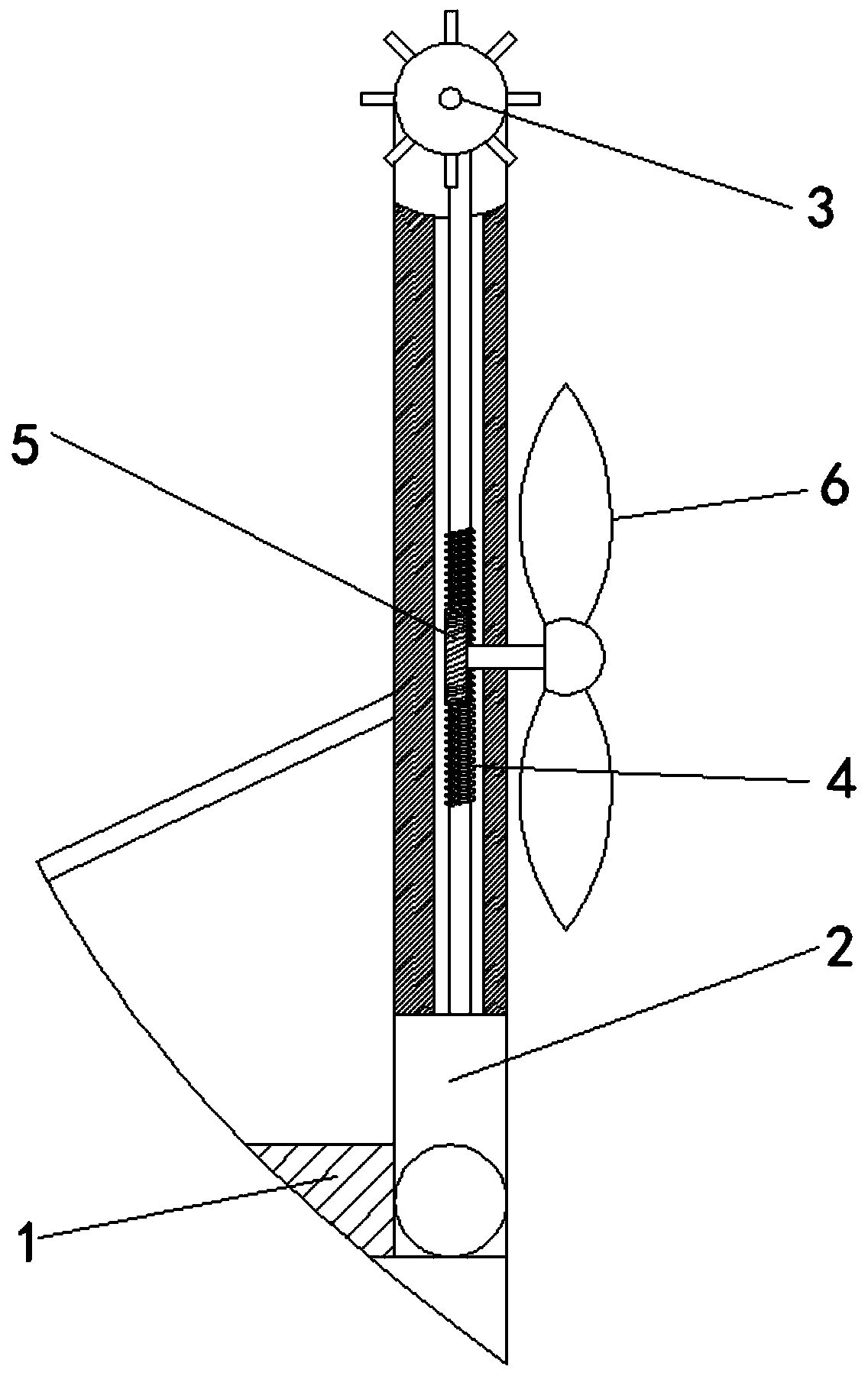

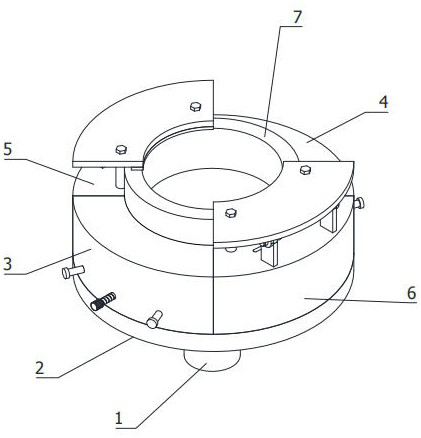

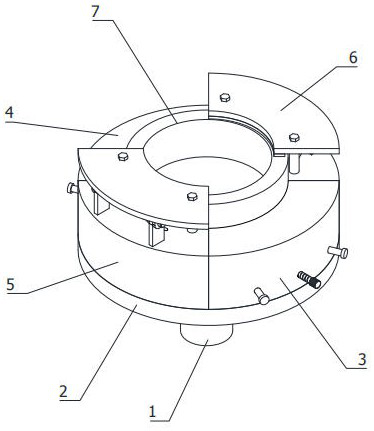

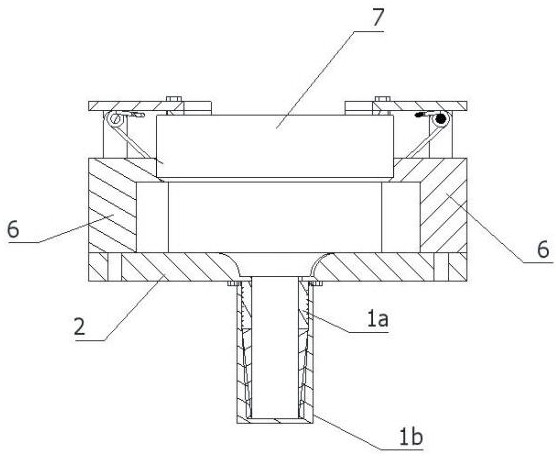

Split-type hopkinson torsion bar energy storing and releasing device as well as operation method thereof

ActiveCN108645696AGuaranteed repeatabilityPracticalMaterial strength using steady torsional forcesEngineeringEnergy analysis

The invention discloses a split-type hopkinson torsion bar energy storing and releasing device as well as an operation method thereof, which can realize impact torsion energy storing and releasing bya simple mechanical structure. The apparatus comprises a hopkinson incident bar, a clamping mechanism, a releasing mechanism, and a guiding mechanism. The operating method is characterized in that theHopkinson incident bar is clamped by the clamping mechanism and guiding mechanism, the torque storage is realized, by designing the releasing device, the stored torsion energy is subjected to instantrelease, so that the shock loading effect can be simulated, and the impact experiment simulation condition is provided; and at the same time, the loaded shock loading is determined by torsion turns numbers, which is conveniently controlled; the split-type hopkinson torsion bar energy storing and releasing device is suitable for different loading devices, and is repeatedly usable without materialconsumption. The device has the advantages of simple structure, low cost, easy control, and convenient operation.

Owner:XI AN JIAOTONG UNIV

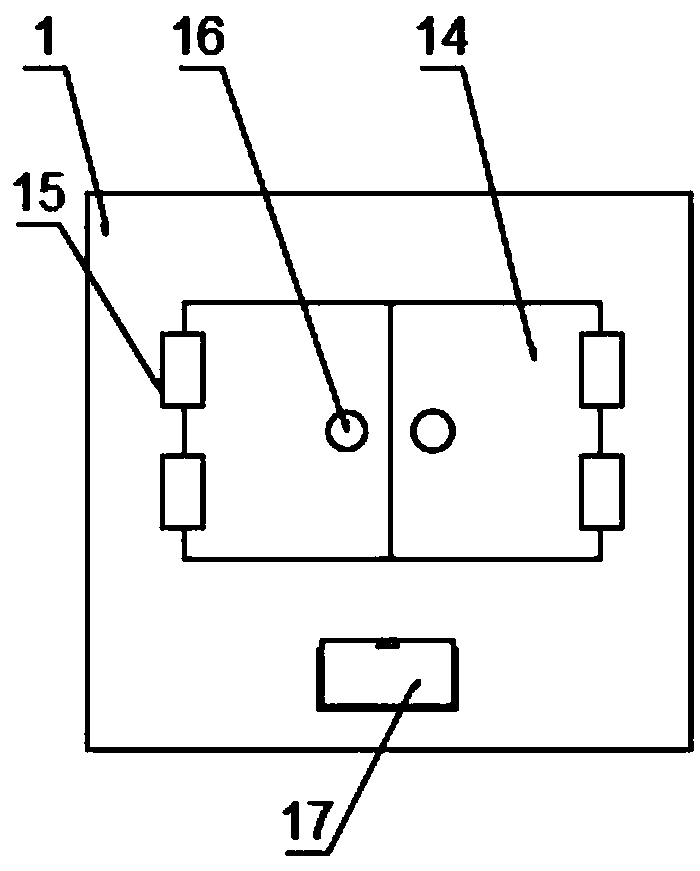

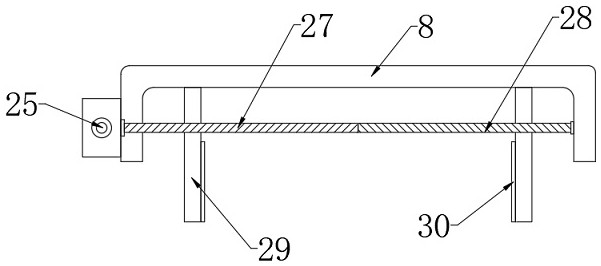

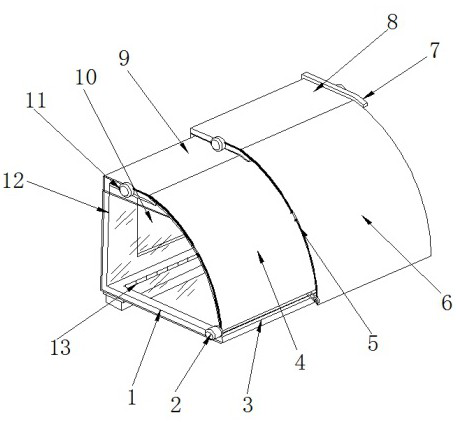

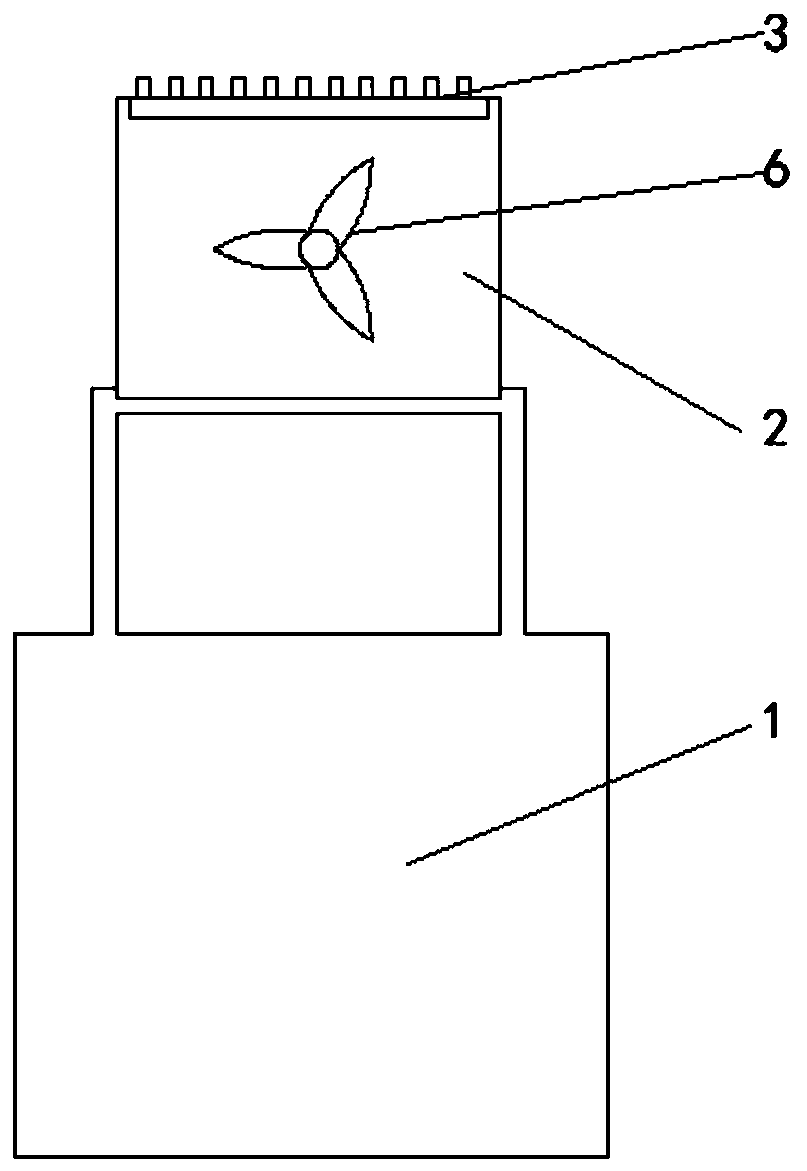

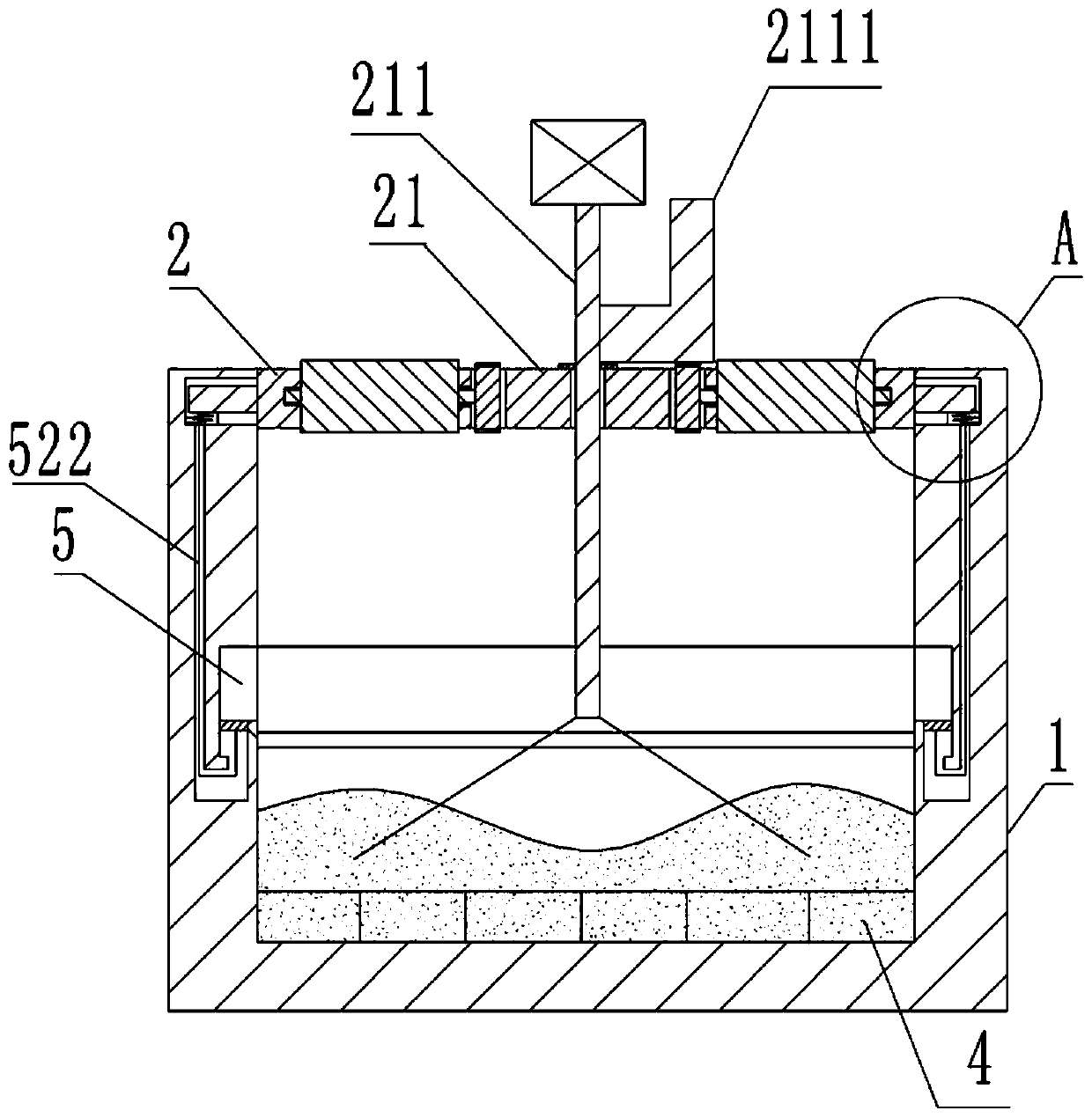

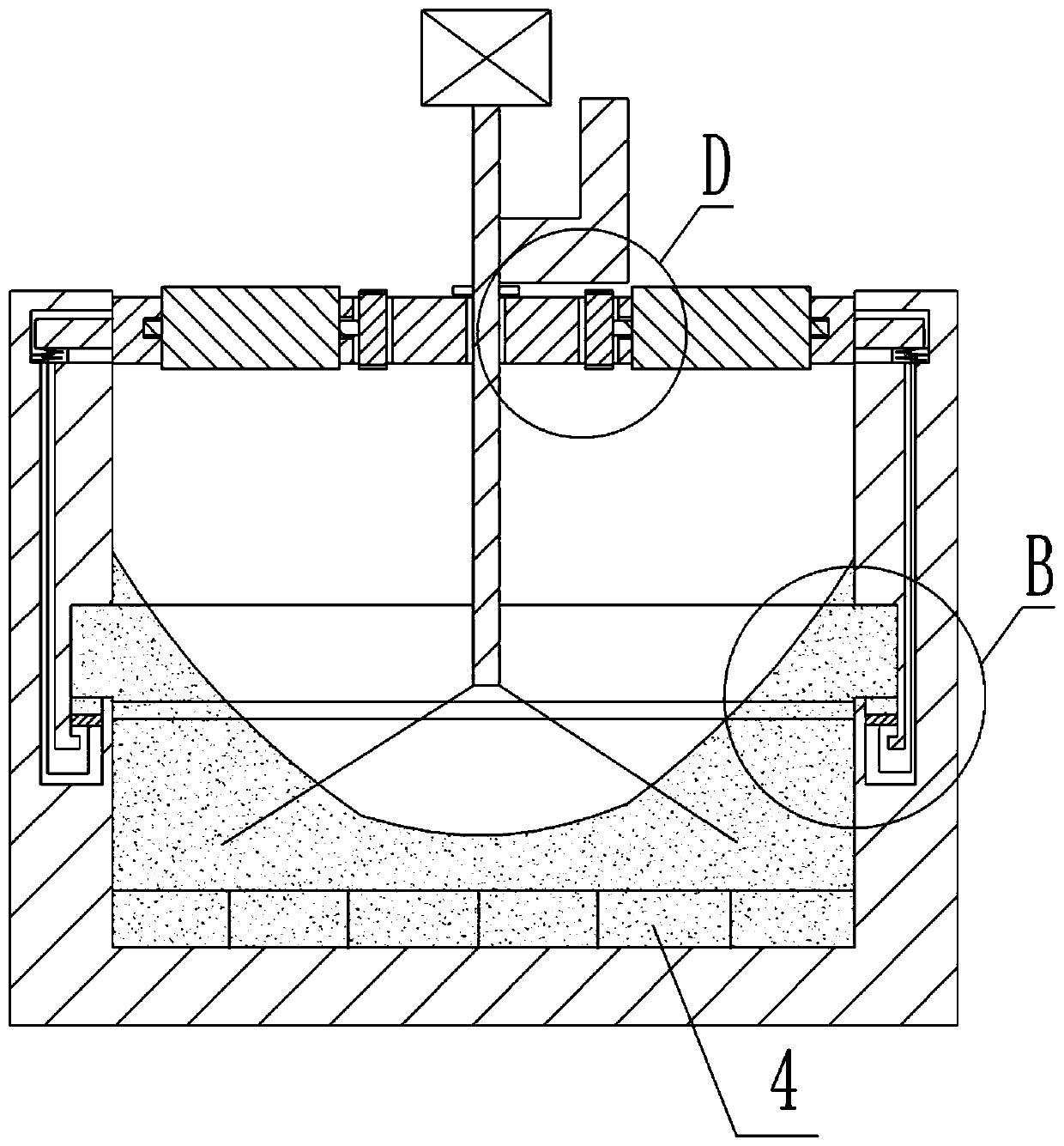

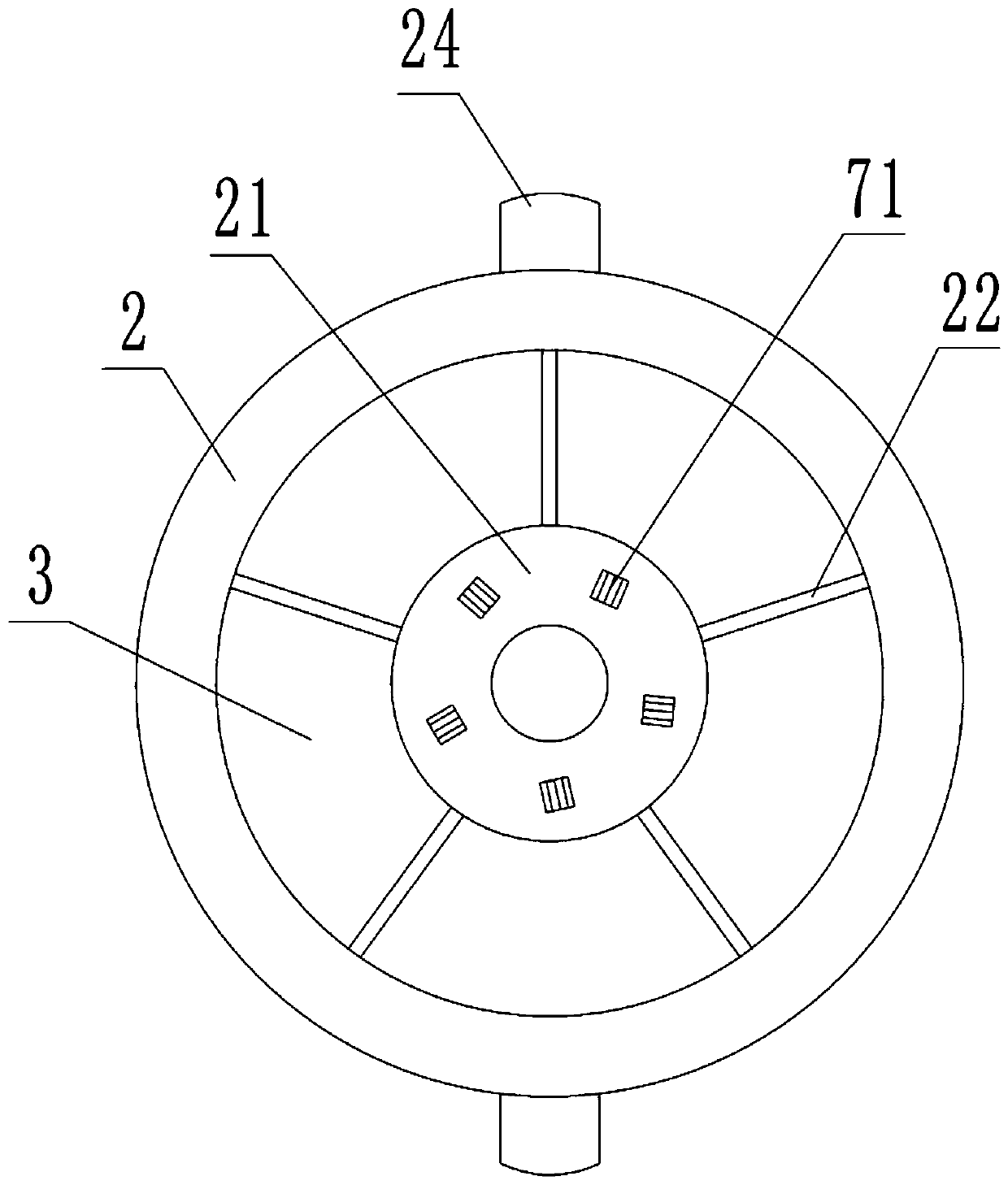

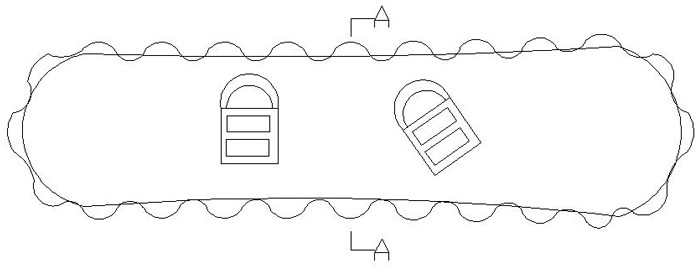

Activated carbon drying processing system and activated carbon drying processing system method

ActiveCN109282627ANot easy to appear dead angleNot easy to dry at allDrying machine combinationsDrying chambers/containersActivated carbonEngineering

The invention relates to an activated carbon drying processing system and an activated carbon drying processing system method. The system comprises a shell, an opening and closing mechanism and a rotating mechanism. The opening and closing mechanism is mounted at the front end of the shell. The rotating mechanism is mounted inside the shell. The opening and closing mechanism comprises an opening and closing motor, a mounting support, a rotating plate, connecting brackets and opening and closing plates. The rotating mechanism comprises a rotating motor, a working bracket, a rotating gear, rotating rollers, a screw rod, a fixing bracket, a moving plate, a connecting extending-and-contracting rod, push rods, baffles, auxiliary rods and brush hair. By means of the activated carbon drying processing system, the problems that in the existing activated carbon drying process, a dead corner is likely to be caused, drying is incomplete, and activated carbon is likely to be wasted are solved; thefunction of automated assistance can be achieved in the activated carbon drying process; and the activated carbon drying processing system has the advantages that the dead corner is not likely to becaused, drying is conducted completely, and materials are not likely to be wasted.

Owner:HANGZHOU FORASEN TECH

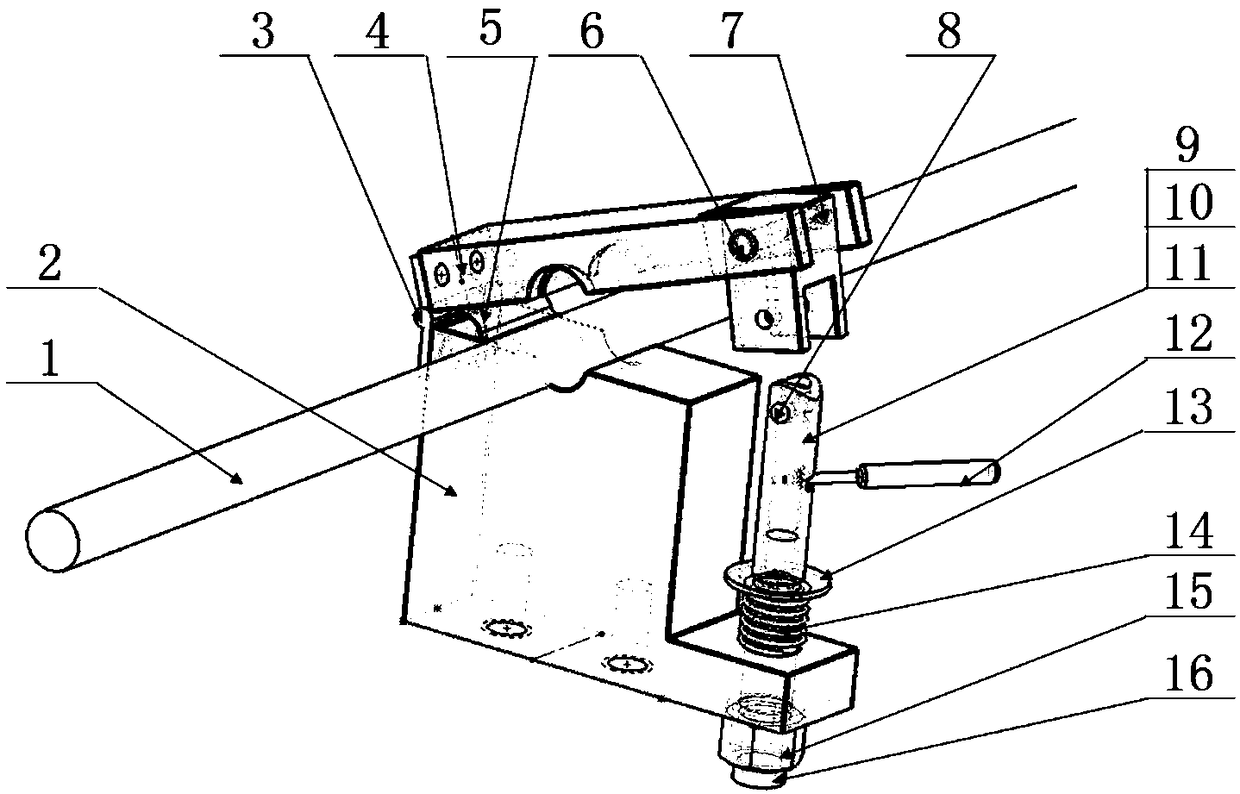

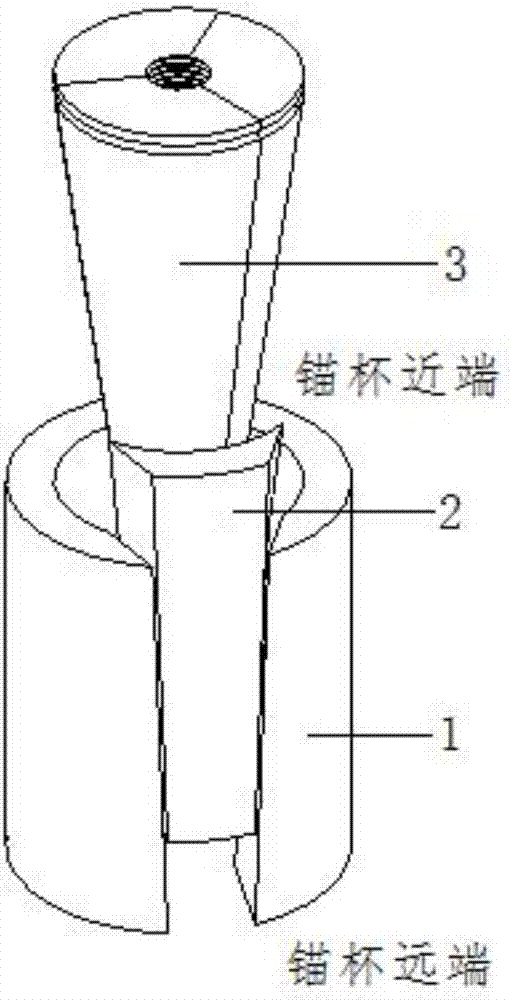

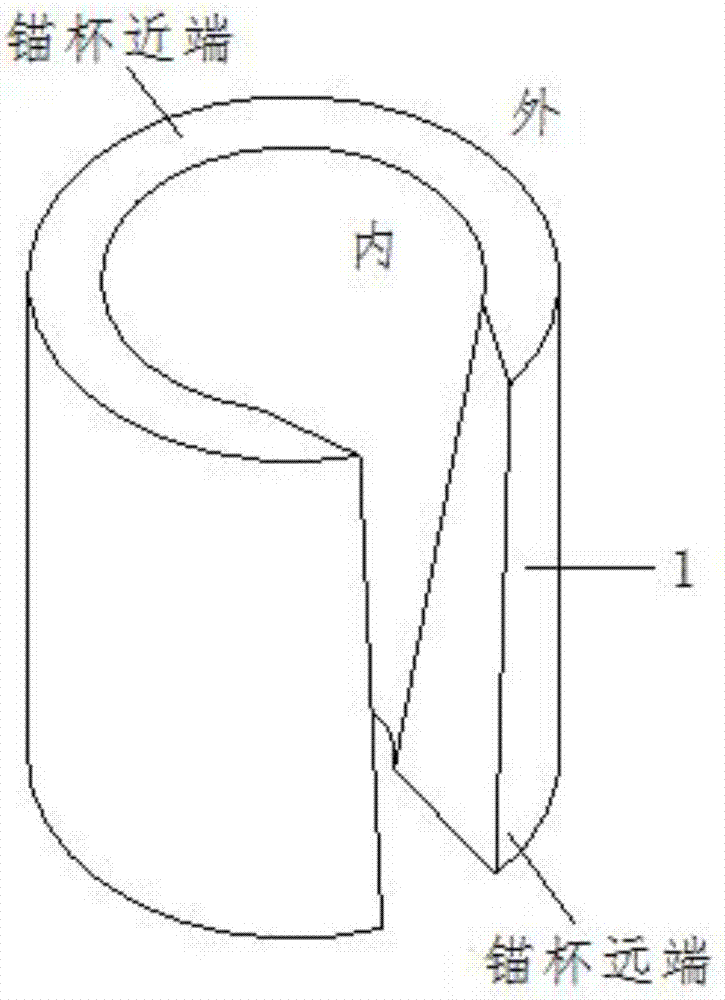

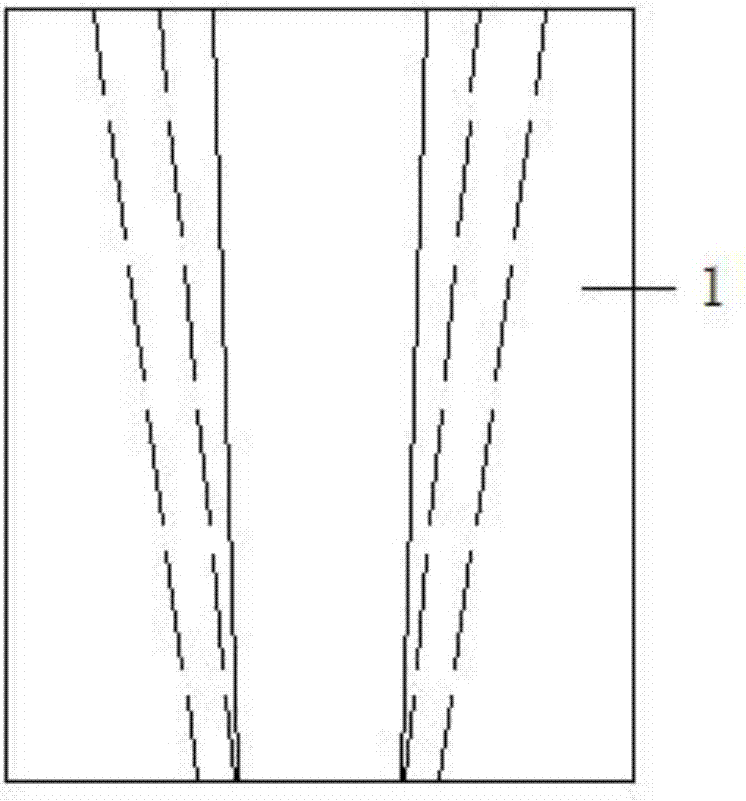

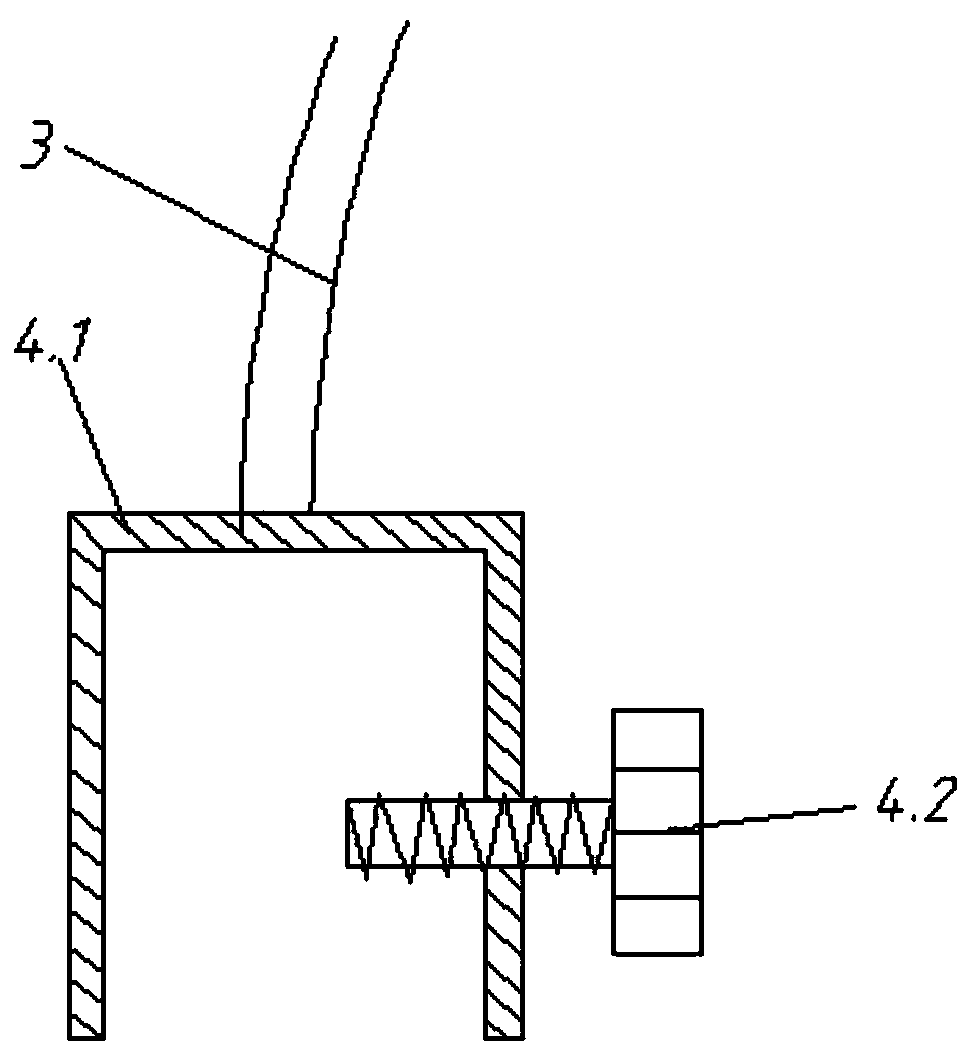

Tool anchor used for dismantling unbonded prestressed concrete structure and using method thereof

ActiveCN106968400AWon't fly outBuilding repairsBuilding reinforcementsPre stressPrestressed concrete

The invention discloses a tool anchor used for dismantling an unbonded prestressed concrete structure and a using method thereof and belongs to the field of civil engineering. The tool anchor and the using method thereof are used for dismantling the unbonded prestressed concrete structure and solving the problem that safety is poor when the unbonded prestressed concrete structure is dismantled. The tool anchor used for dismantling the unbonded prestressed concrete structure is composed of three parts of an anchor cup provided with an irregular notch, an irregular plugging bock and a matched clamping piece. The method comprises the steps that at the beginning of dismantling the unbonded prestressed concrete structure, concrete which is located around an unbonded tendon and located within the range being no less than 120 mm and with the clear distance from a work anchorage device at the anchoring end on one side being about 1.0 m or above is removed; an unbonded tendon protective sleeve is stripped, the anchor cup provided with the irregular notch is used to encircle a prestressed tendon, the matched clamping piece is inserted between the prestressed tendon and the inner wall of the anchor cup, the irregular plugging bock is pushed into the notch of the cup wall, and a small hammer is used to strike the matched clamping piece to enable the matched clamping piece to be in a jam-pack state between the prestressed tendon and the inner wall of the anchor cup; and a work anchorage device on the other side is removed, and then follow-up dismantling work is conducted.

Owner:HARBIN INST OF TECH

System and method of chamber destruction of bomb

The invention discloses a system and method to destroy bomb in underground chamber that is made up of destroying underground chamber located in wall rock and the bottom has impacting resistance material layer, adit and communicating laneway that has laneway structure. The destroying underground chamber connects to adit through laneway. After setting the system, laying the bomb and blasting charge into the underground chamber to take remote detonation and take forced draught after detonating to release the waste gas into atmosphere and the harmful gas thickness would be lowered to safe range. The system would destroy 200kg detonator equivalent weight bomb, and the bow wave would not harm human over 200m distance. Even in the area of popuousness.

Owner:GUANGDONG HONGDA BLASTING

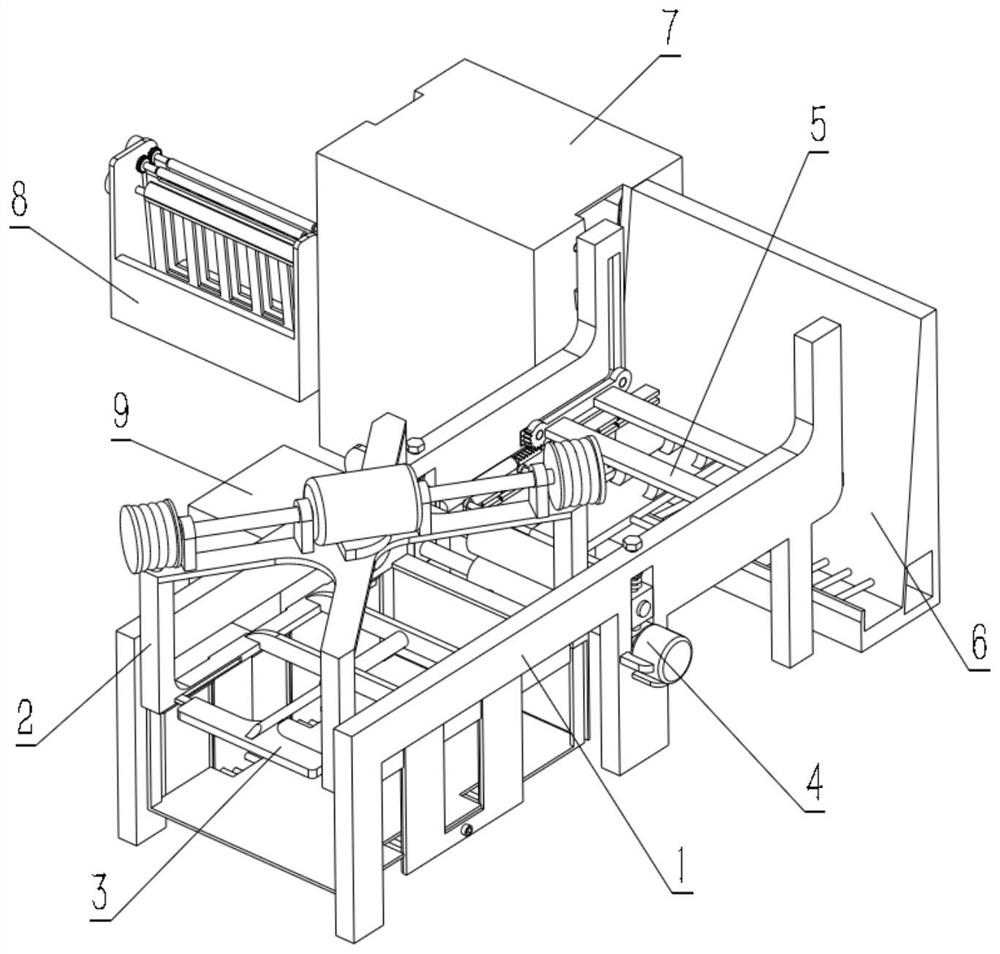

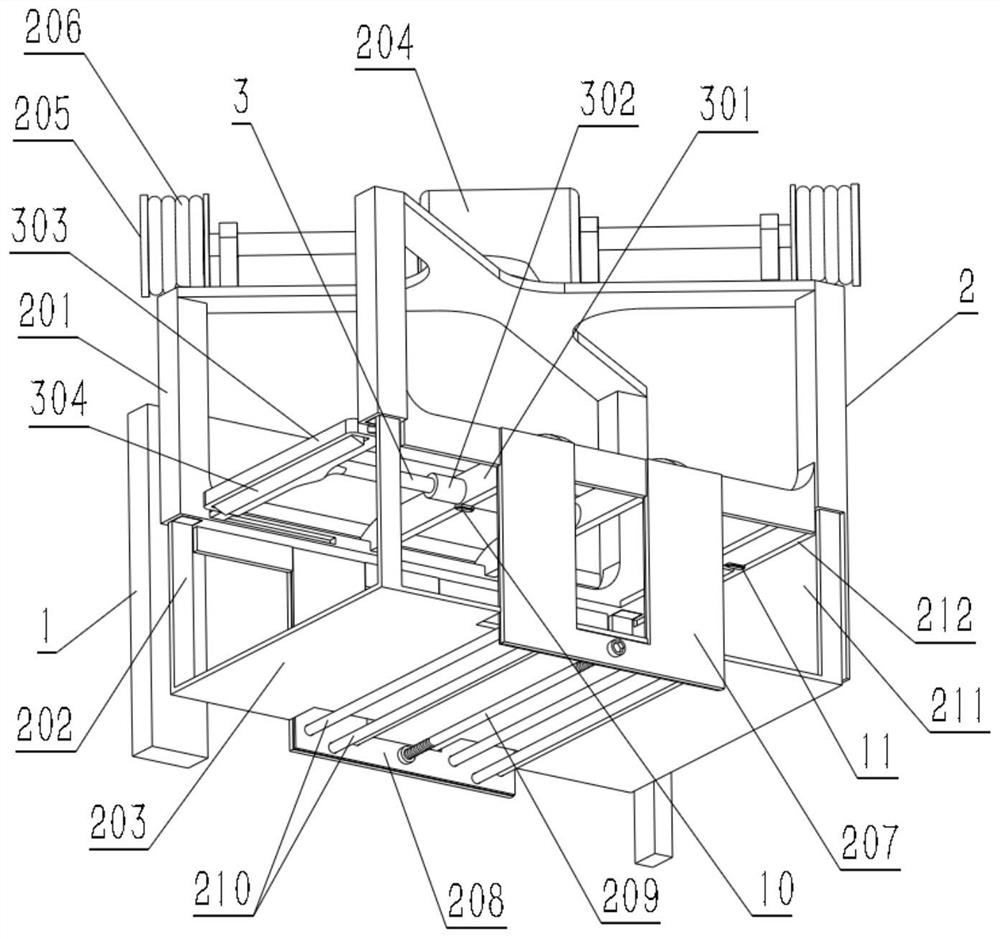

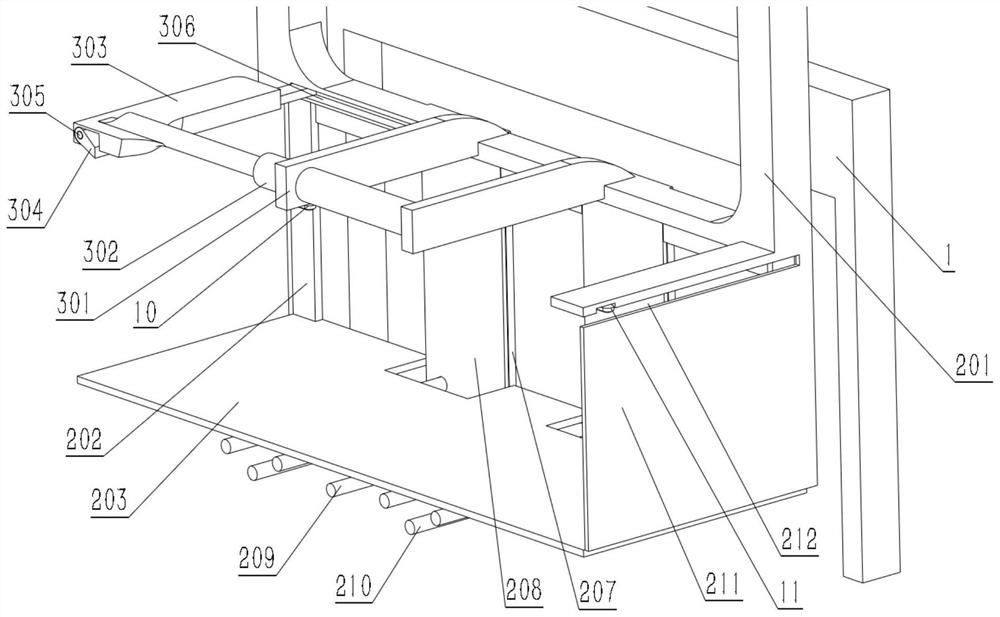

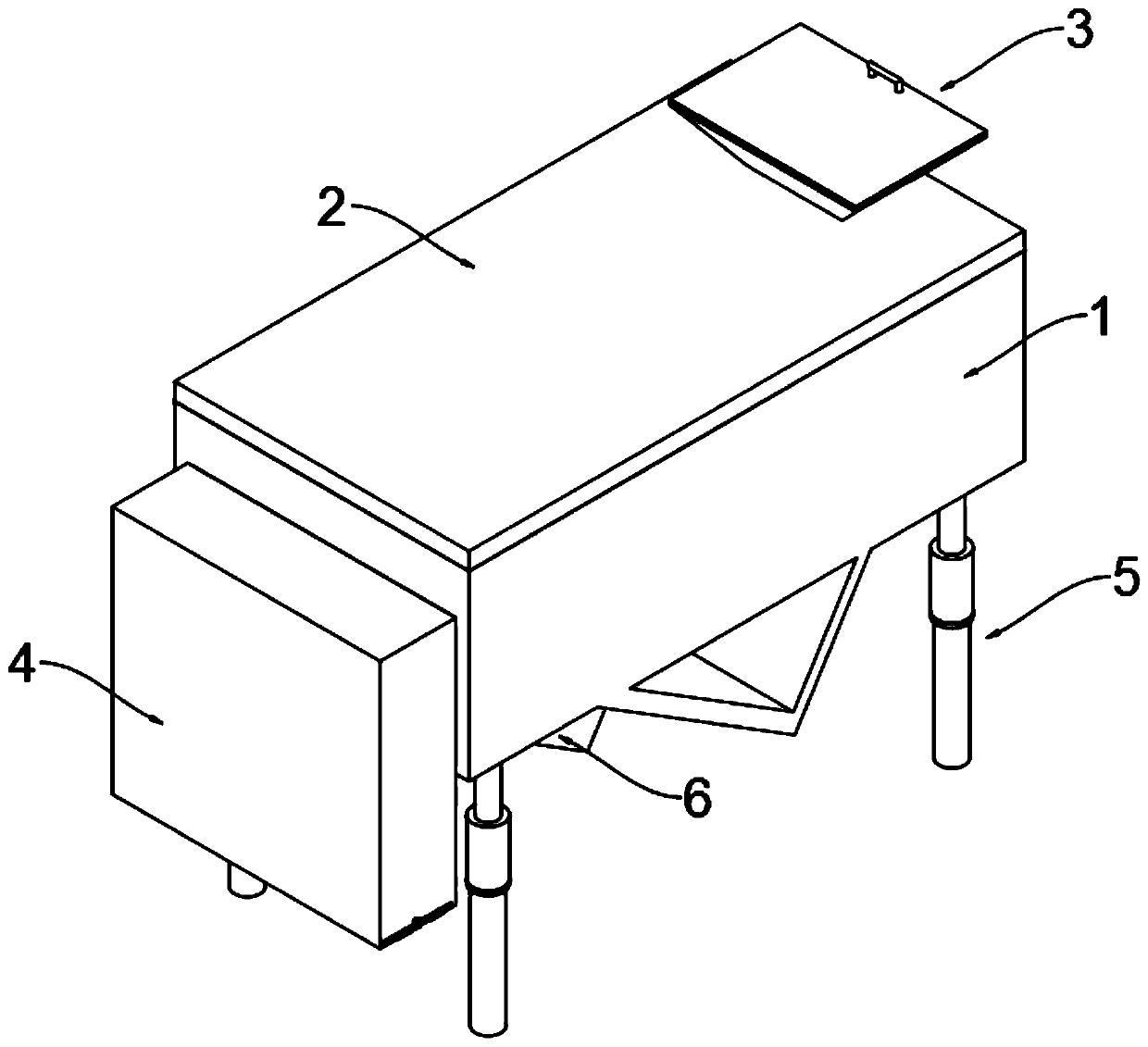

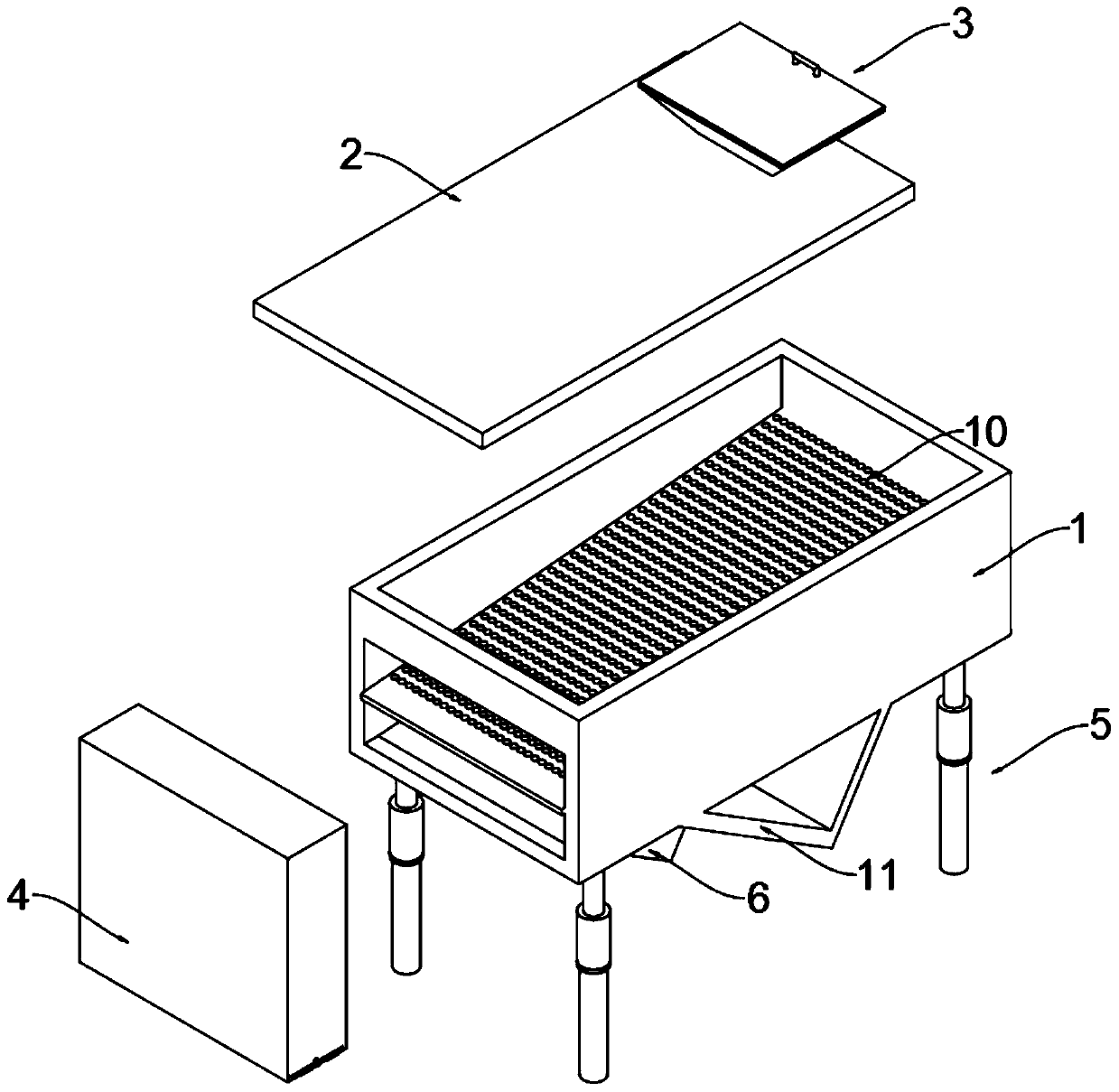

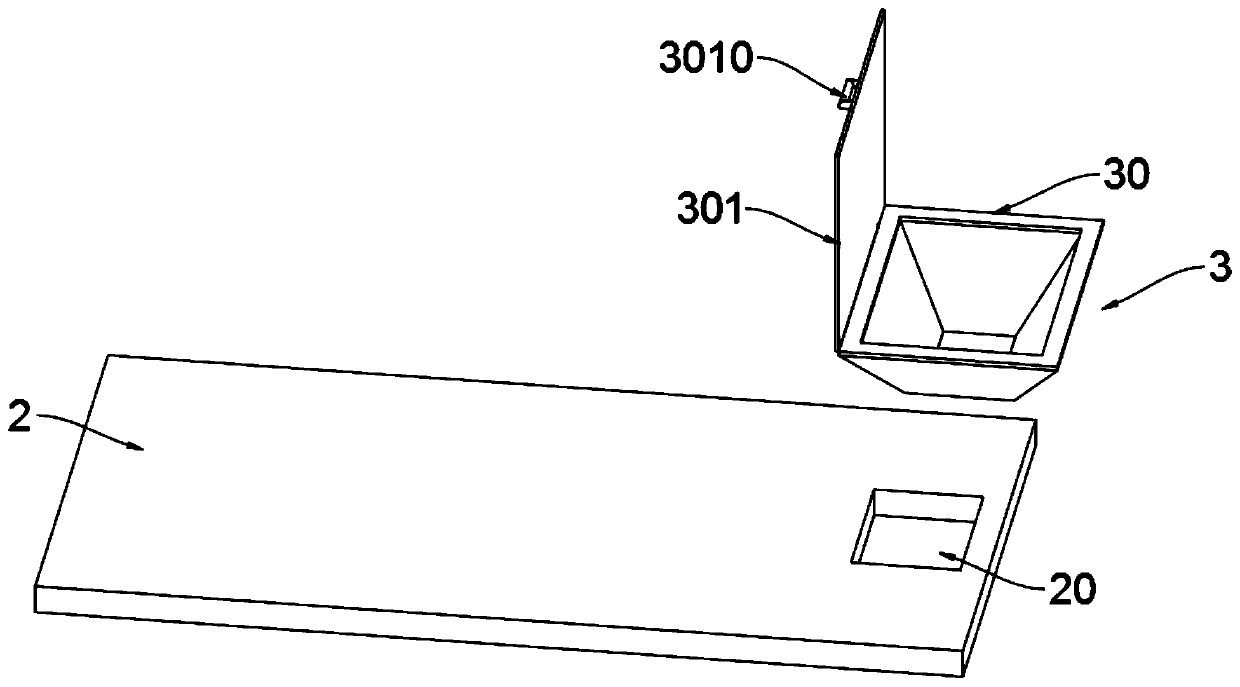

Intelligent manufacturing device for large plate polishing production

ActiveCN114571329AImprove efficiencyEasy to grindGrinding drivesBelt grinding machinesProcess engineeringManufacturing line

The invention relates to an intelligent manufacturing device for large plate polishing production. By combining a production line machining mode and utilizing cooperation of the feeding frame, the plate pushing device and the feeding device, automatic feeding of large plates can be achieved, reverse rotation of the large plates can be rapidly and effectively completed through the plate overturning device, the large plates are changed into an inclined vertical state from a horizontal state, and therefore later grinding machining is facilitated, and the production efficiency is improved. The discharged plate turnover device can turn over the polished plates, so that the plates are stacked or transferred to other processing procedures; according to the whole device, multiple sets of equipment are combined, the grinding machining efficiency of large plates is effectively improved, grinding stations are arranged in a centralized mode, dust removal equipment can be arranged conveniently, the influence of dust generated in the grinding process on the environment is reduced, the layout of the whole device is more reasonable, the occupied area is saved, the requirement for the area of a plant is reduced, and cost is effectively saved.

Owner:WUHAN TECHN COLLEGE OF COMM

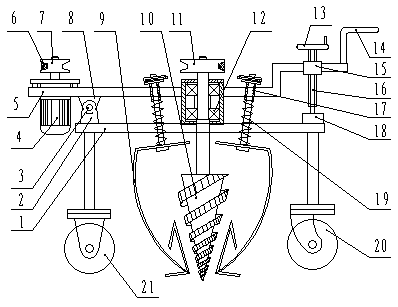

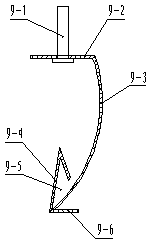

V-shaped grooving machine for pavement bending crack repairing construction

PendingCN111236034AGood crushing performanceSave human effortDirt cleaningRoads maintainenceElectric machineryHandrail

The invention provides a V-shaped grooving machine for pavement bending crack repairing construction. The machine comprises an upper machine frame and a lower machine frame, a flying dust collecting device, a grooving device, a motor, a triangular belt, a motor belt wheel, an upper twisting seat, a bearing, a grooving belt wheel, a dust collecting spring, a guide sleeve, a handrail and a nut whichare installed on the upper machine frame, and a universal wheel, a supporting land wheel, a lower twisting seat and a screw rod seat which are installed on the lower machine frame, the left ends of the upper machine frame and the lower machine frame are hinged through a hinge seat shaft through which the upper hinge seat and the lower hinge seat are communicated in series; the grooving machine ischaracterized in that the surface of a conical cutter body of the grooving machine is provided with cutting edges which are arranged on a plurality of spiral lines with the screw pitches gradually reduced from top to bottom, the overall dimensions of the cutting edges are gradually reduced, and the two hollow semi-drum-shaped flying dust collecting devices are symmetrically installed on the leftside and the right side of the grooving machine. According to the machine, a V-shaped groove can be cut at a time in the pavement crack bending direction, and cut powder settles in a dust collecting cavity in the bottom of the flying dust collecting device.

Owner:SHANDONG UNIV OF TECH

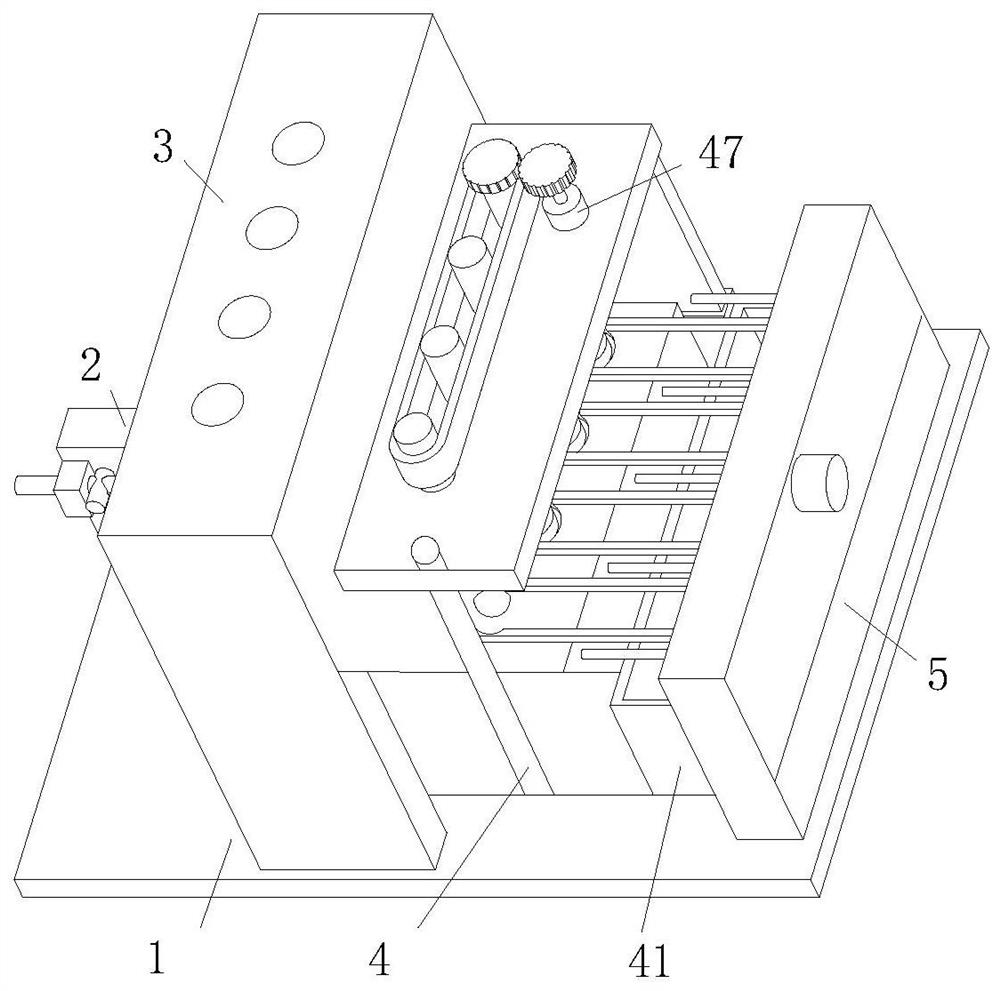

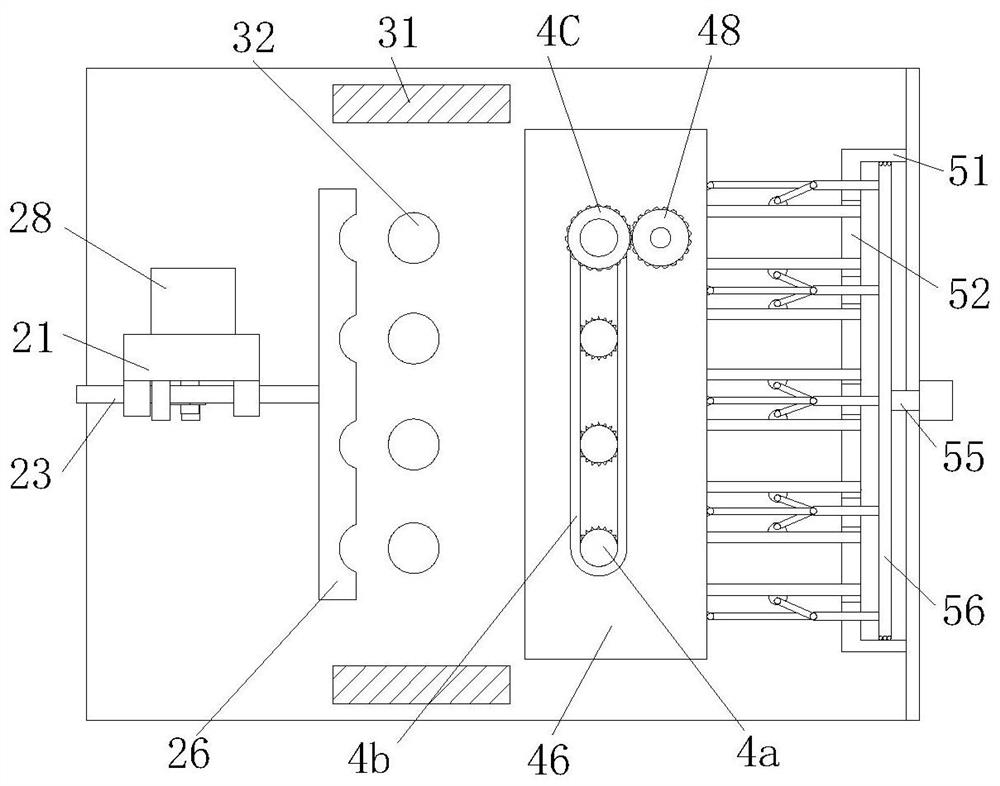

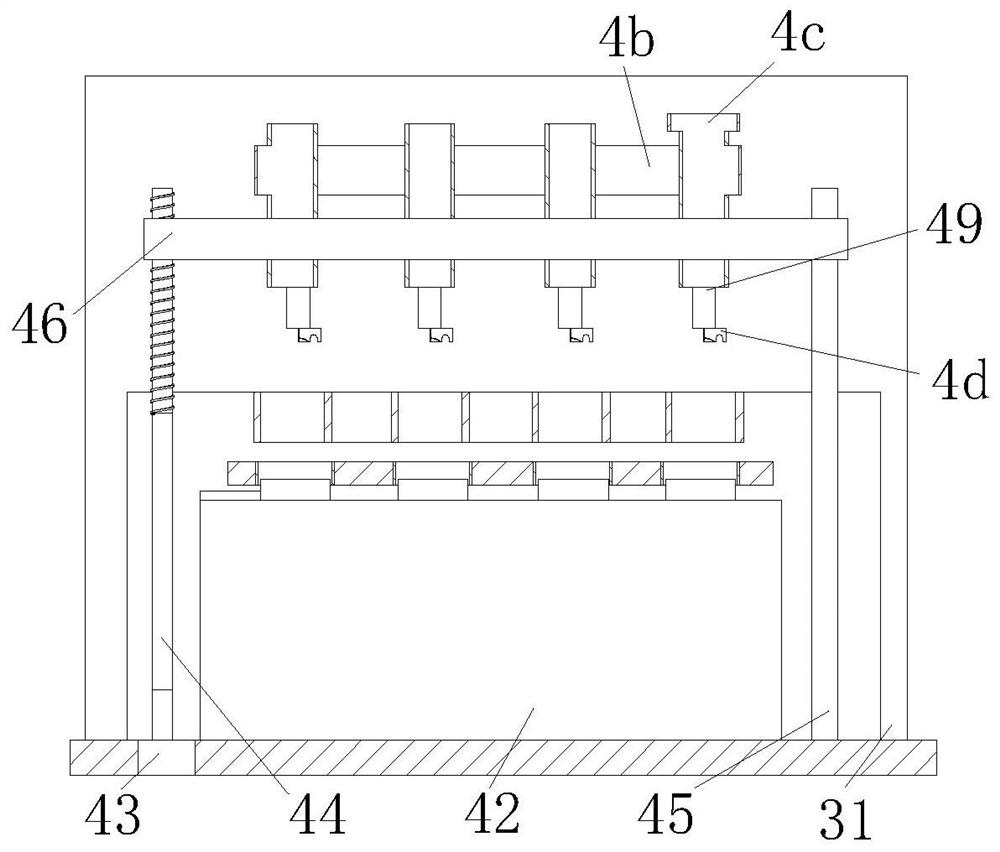

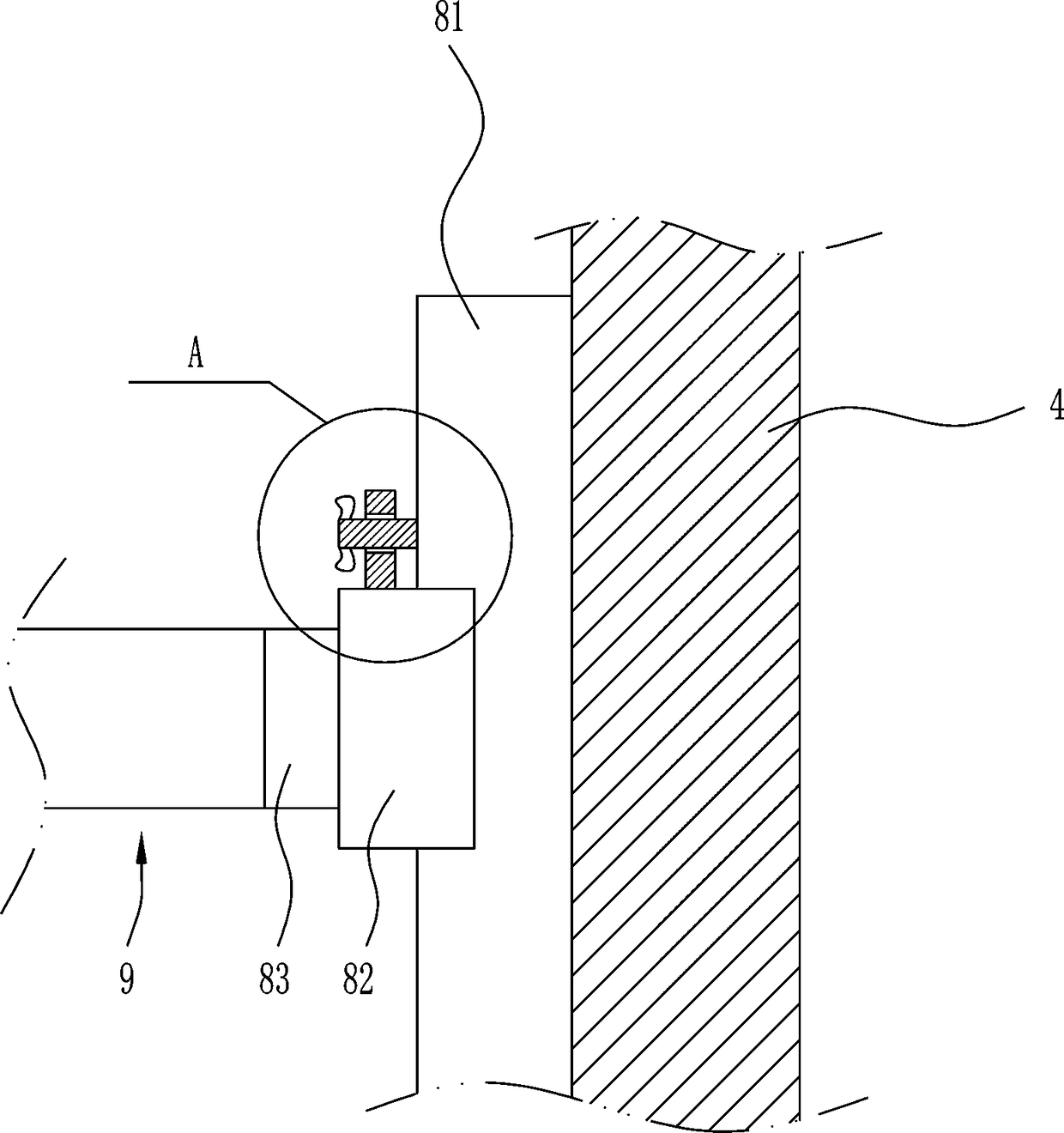

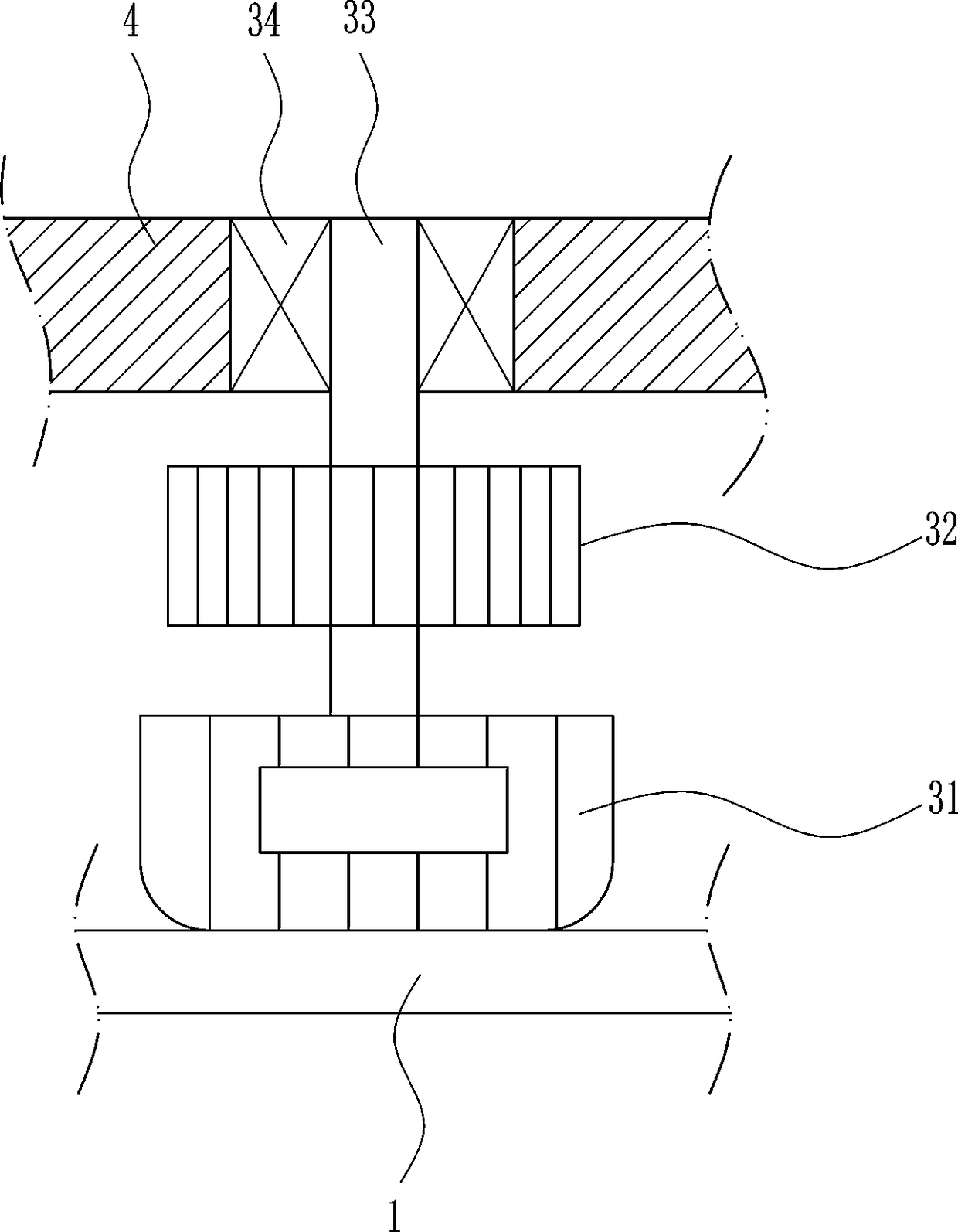

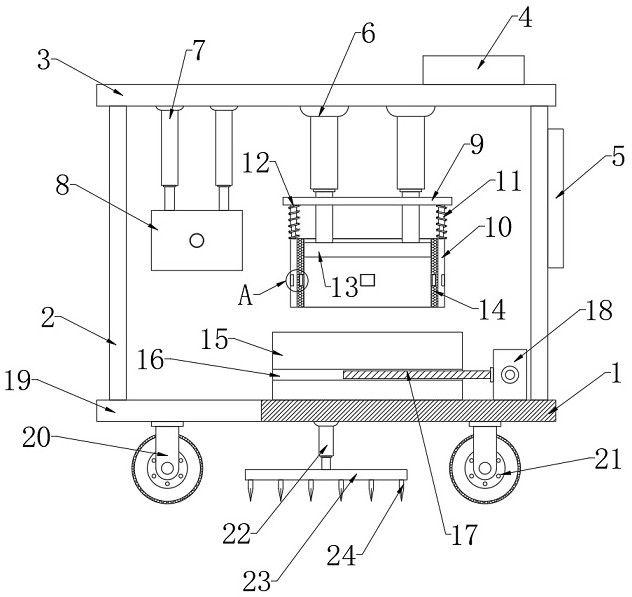

Automatic polyester button processing assembly line

ActiveCN112192655AImprove applicabilityImprove work efficiencyMetal working apparatusPolyesterEngineering

The invention relates to an automatic polyester button processing assembly line. The assembly line comprises a workbench, a material pushing device, a feeding device, a drilling device and a clampingdevice; the material pushing device, the feeding device, the drilling device and the clamping device are sequentially arranged on the upper end face of the workbench from left to right; and the clamping device comprises a concentric-square-shaped block, a first rectangular groove, a clamping plate, a protruding block, an electric push rod, a push plate, a guiding rod and a supporting rod. According to the automatic polyester button processing assembly line, firstly, a cutter is adjusted according to a needed hole, and therefore the mechanical applicability is greatly improved; a plurality of buttons are fed at the same time through the feeding device, the buttons are pushed to the positions below the drilling device through the material pushing device at the same time, and the buttons areclamped and fixed through the clamping device; and finally, the buttons are drilled by the drilling device, and the working efficiency of machinery during drilling is improved.

Owner:宁波市星矢自动化有限公司

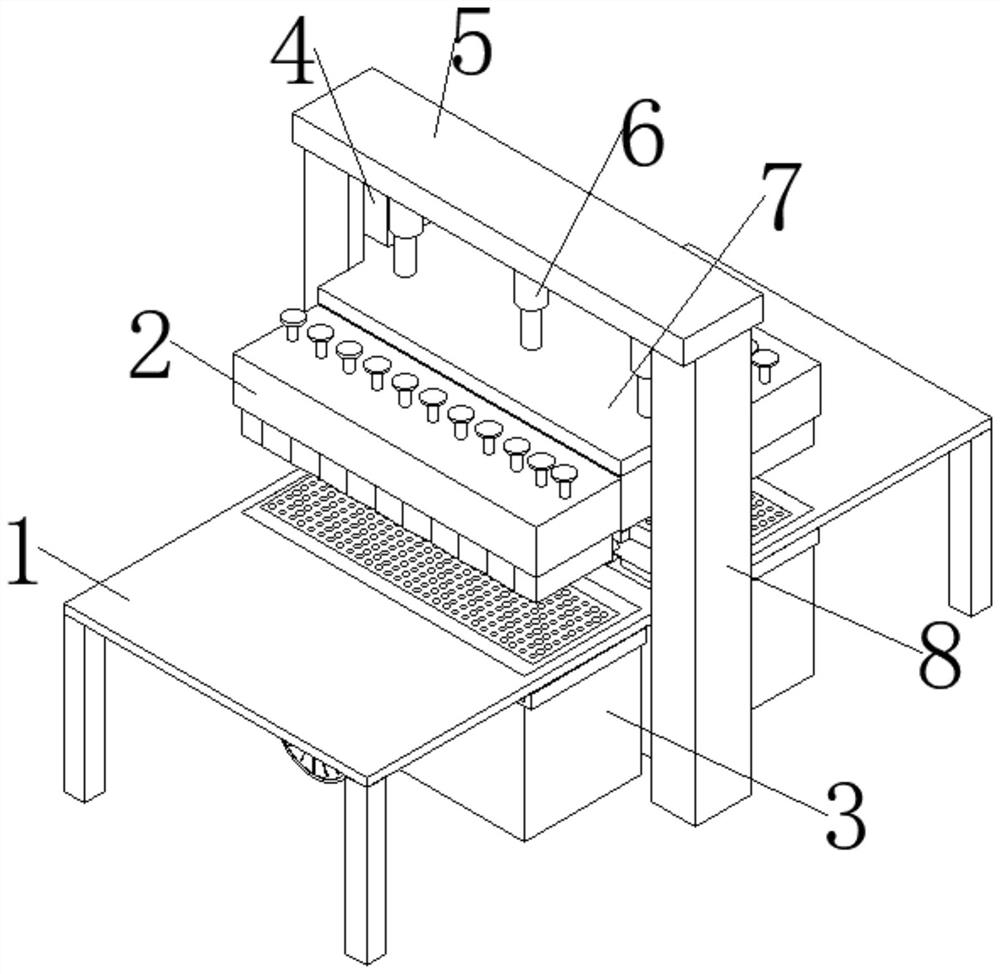

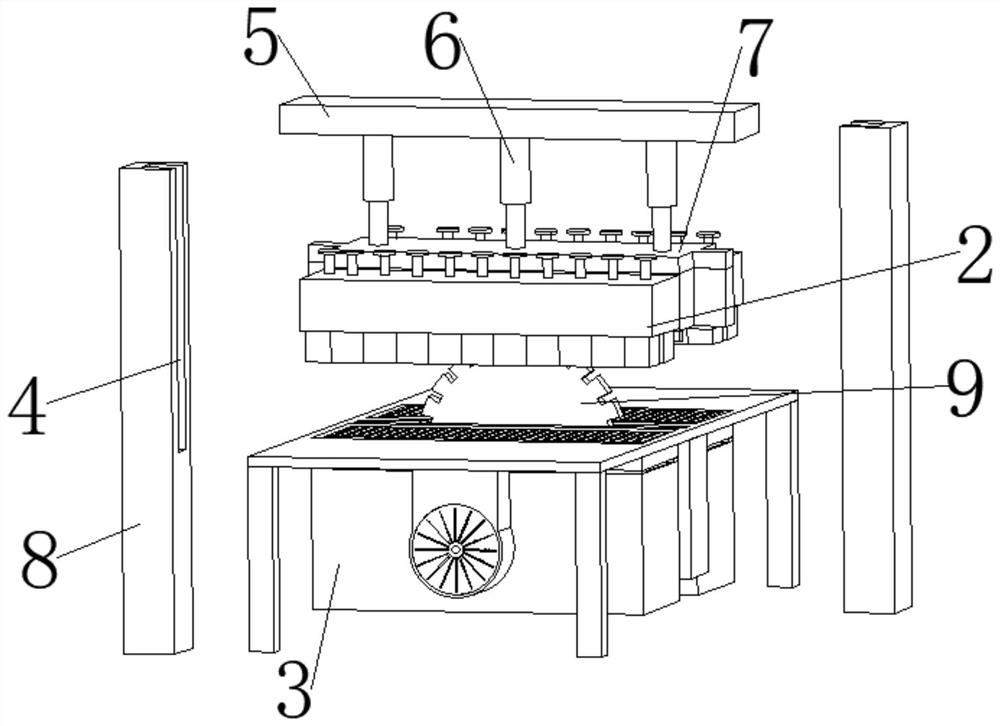

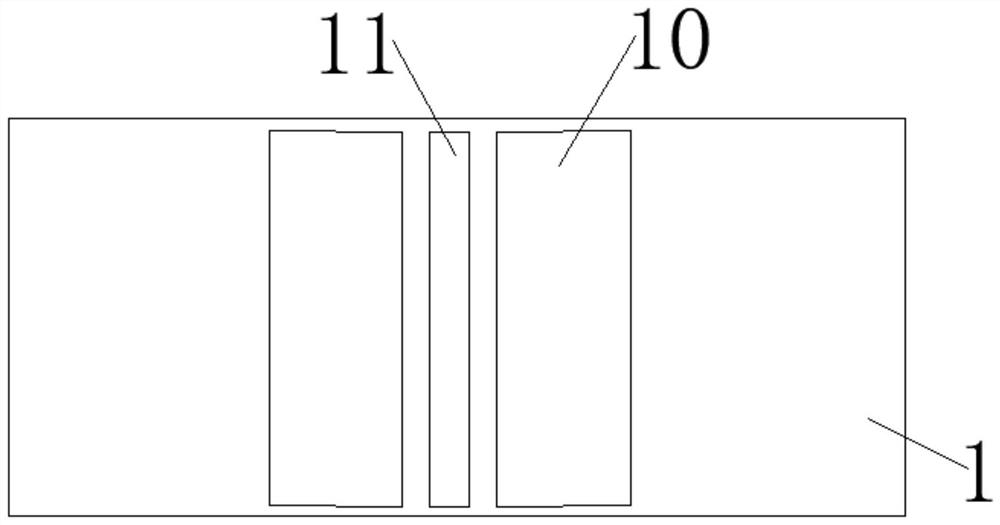

Medical test tube cleaning device

The invention relates to a cleaning device, in particular to a medical test tube cleaning device. According to the technical aims to be achieved, the medical test tube cleaning device is thorough in cleaning and has the function of drying disinfection. In order to achieve the above technical aims, the medical test tube cleaning device comprises a bottom plate, a supporting seat, a drive mechanism,a cleaning box, a water outlet pipe, a cleaning mechanism, a lifting mechanism, a clamping mechanism, a cover plate and a fixed mechanism. The supporting seat is fixedly connected to the top of the bottom plate in the vertical direction. The cleaning box is fixedly connected to the top of the supporting seat. The drive mechanism is fixedly connected to the bottom plate. The cleaning mechanism isfixedly connected to the bottom of the cleaning box. The medical test tube cleaning device achieves the effects of thoroughly cleaning multiple test tubes and relieving the work intensity of medical staff.

Owner:HEBI CITY PEOPLES HOSPITAL

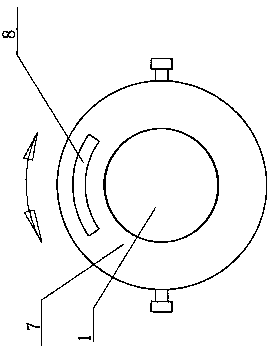

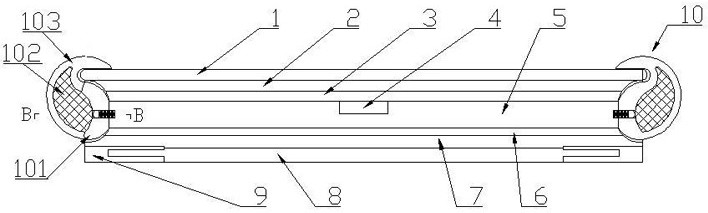

Linear vibrating screen

The invention relates to the technical field of linear vibrating screens, in particular to a linear vibrating screen which comprises a vibrating box. A top cover is arranged on the top part of the vibrating box; a feed inlet is formed in the position, close to the right end edge part, on the upper surface of the top cover; a feeding device is arranged above the feed inlet; a sieve plate is arranged in the middle of the vibrating box; an opening is formed in the left end surface of the vibrating box; a collecting box is arranged on the left side of the opening; an opening is formed in the bottom part of the collecting box; an L-shaped baffle plate is arranged in the collecting box; the protruded end of the L-shaped baffle plate corresponds to an outlet groove; support leg devices are arranged at the positions, close to four corner parts, on the bottom part of the vibrating box; an L-shaped fixed plate is arranged on the lower surface of the vibrating box; and a vibrating motor is arranged on the L-shaped fixed plate. The linear vibrating screen is provided with the feeding device and the collecting box; and by sealing the whole device, in the use process, flying dust cannot fly outof the whole vibrating box, so that a user can operate the device conveniently without being affected.

Owner:石城县华辉选矿设备制造有限公司

U-shaped grooving machine for pavement bending crack repairing construction

PendingCN111236035AAvoid the defect that it is not easy to change the cutting directionImprove crushing effectDirt cleaningRoads maintainenceElectric machineryRoad surface

The invention provides a U-shaped grooving machine for pavement bending crack repairing construction. The grooving machine comprises a dust collecting device, a grooving device, a motor, a triangularbelt, a motor belt wheel, an upper twisting seat, a grooving device belt wheel, a bearing, a depth scale, a handrail, a nut, a guide sleeve and a dust collecting spring which are installed on an uppermachine frame, and a lower twisting seat, a screw rod seat, a universal wheel and a supporting ground wheel which are installed on a lower machine frame. The left ends of the upper machine frame andthe lower machine frame are hinged through a rotating shaft through which the upper hinge seat and the lower hinge seat are communicated in series; the grooving device is positioned at the right end through a hand wheel and a screw rod according to the depth scale; the grooving machine is characterized in that a cutter body of the grooving device is formed by combining a cylinder and a cone, thesurface is provided with different cutting edges which are arranged along in a dual-head spiral line and protruded outside, the grooving device is surrounded by an inner hollow drum type dust collecting device, a U-shaped groove can be formed in the road surface crack bending direction at a time, cut crushed materials and dust settle in a dust collecting cavity of the dust collecting device, and the road surface crack cutting machine is simple in structure and excellent in working performance.

Owner:SHANDONG UNIV OF TECH

Numerically-controlled machine tool housing

InactiveCN108655814AEasy to collectWon't fly outMaintainance and safety accessoriesNumerical controlEngineering

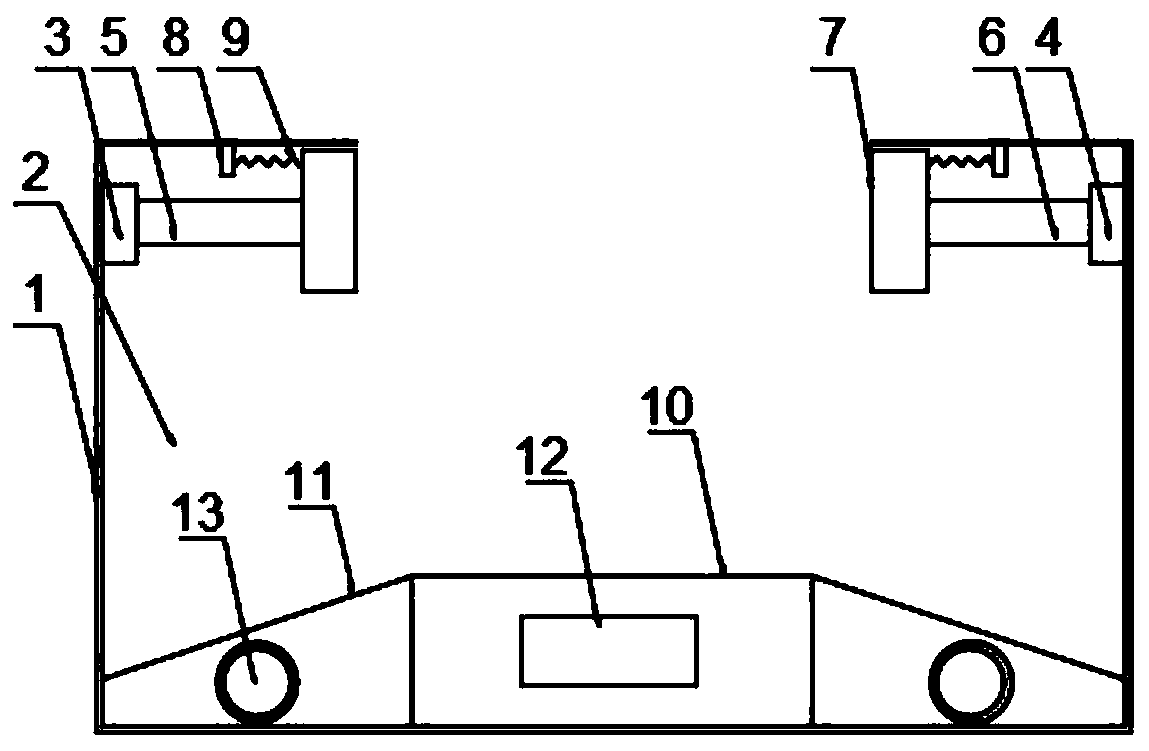

The invention discloses a numerically-controlled machine tool housing. The numerically-controlled machine tool housing comprises a housing body. An accommodating cavity is formed in the housing body.A first base and a second base are arranged on the two side walls inside the accommodating cavity correspondingly. A first telescopic rod is arranged at one end of the first base. A second telescopicrod is arranged at one end of the second base. Clamps are arranged at one ends of the first telescopic rod and the second telescopic rod correspondingly. A workbench is arranged at the bottom end of the accommodating cavity. Oblique plates are arranged on the two sides of the workbench correspondingly. Solenoids are arranged inside the oblique plates correspondingly. A battery is arranged inside the workbench. According to the numerically-controlled machine tool housing, by arranging the clamps at the top end of the accommodating cavity, the housing body is made to be applicable to widths of executing elements of different numerically-controlled machine tools, and accordingly, the application range of the housing body is greatly expanded; and by arranging the solenoids inside the oblique plates correspondingly, wastes produced during machining can be firmly adsorbed to the surfaces of the oblique plates under the effect of a magnetic field, and when needing to be cleared, the wastes can be collected in a unified mode by interrupting power supply to the solenoids.

Owner:芜湖遥帆电子科技有限公司

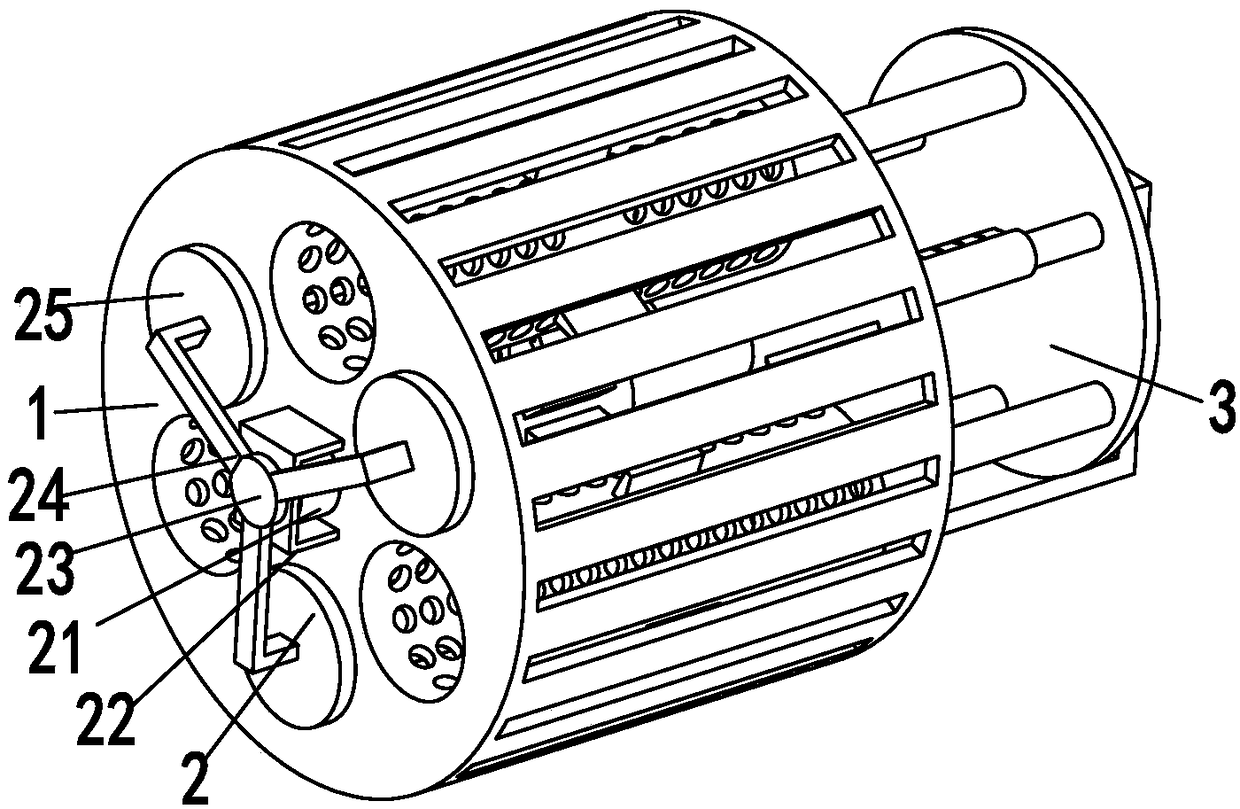

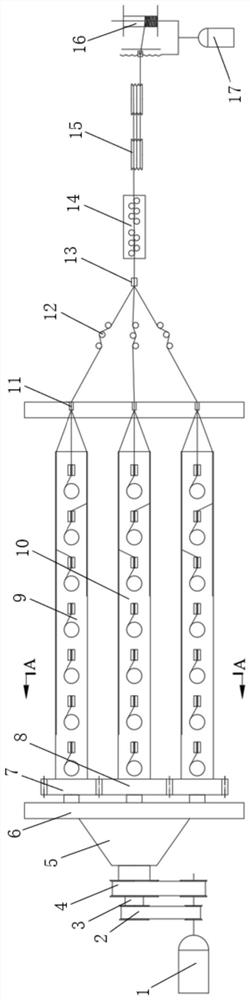

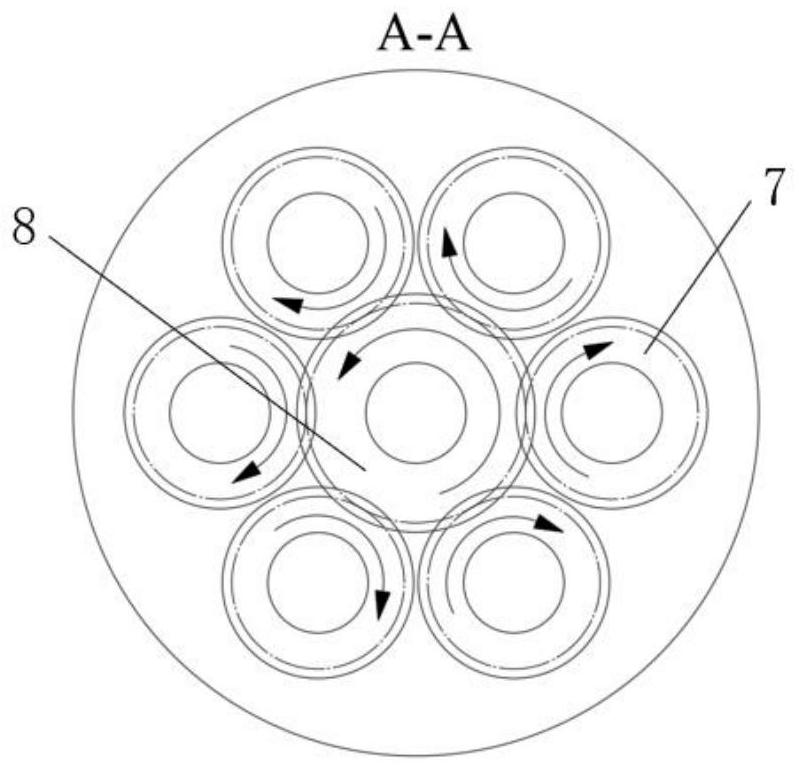

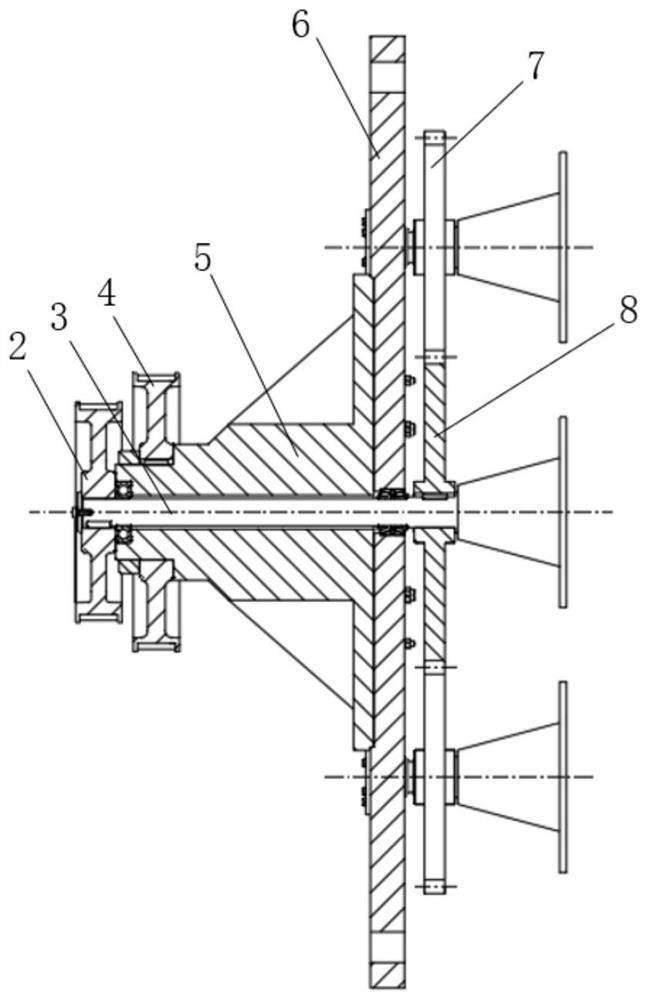

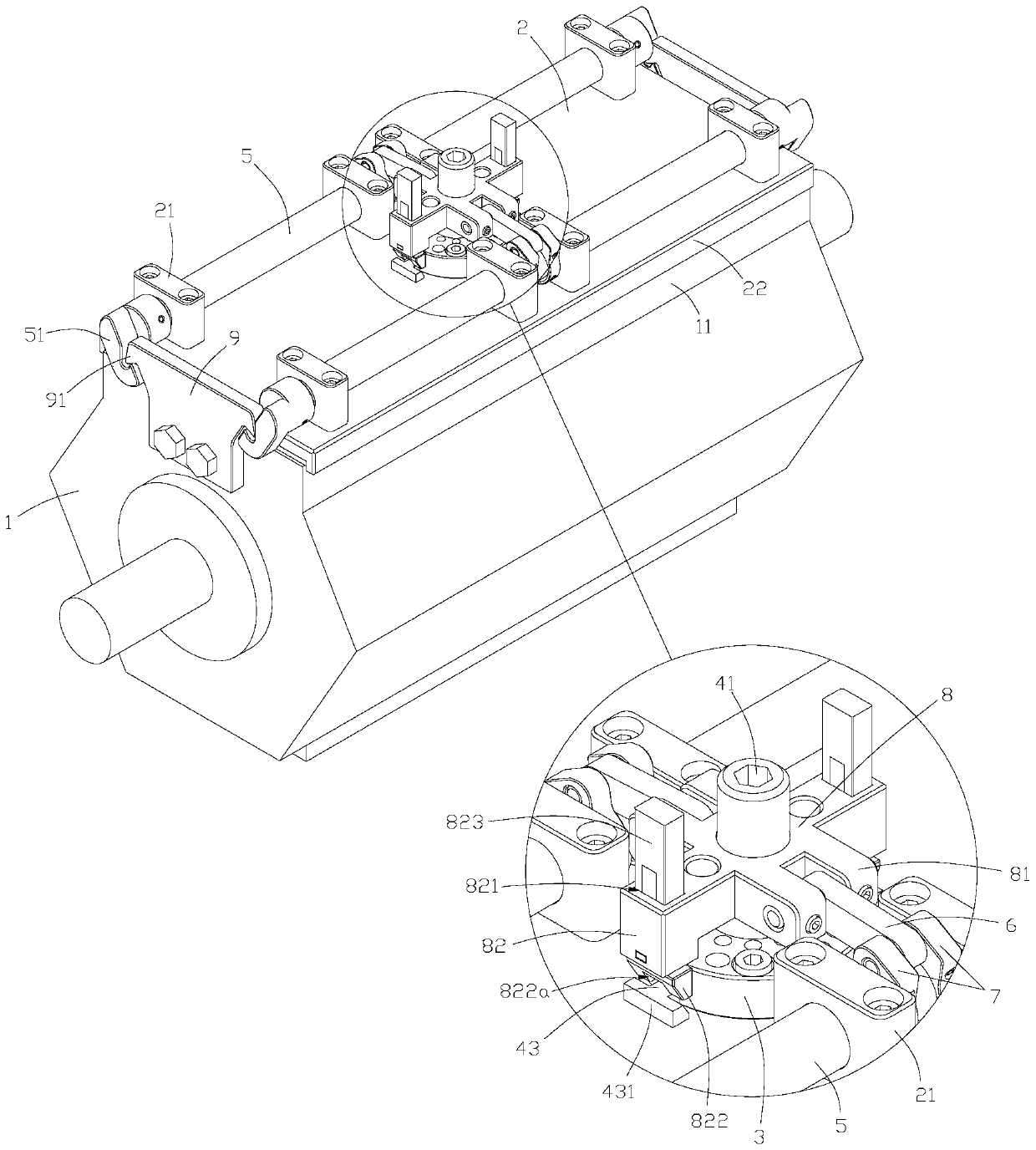

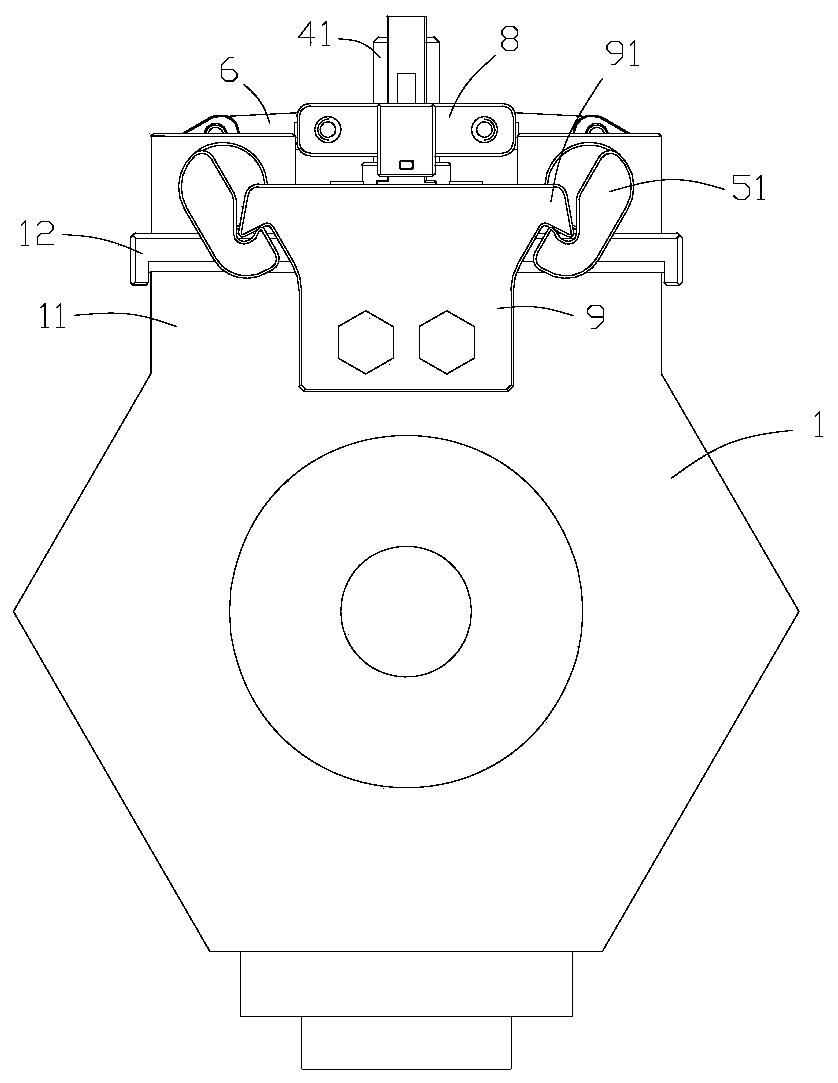

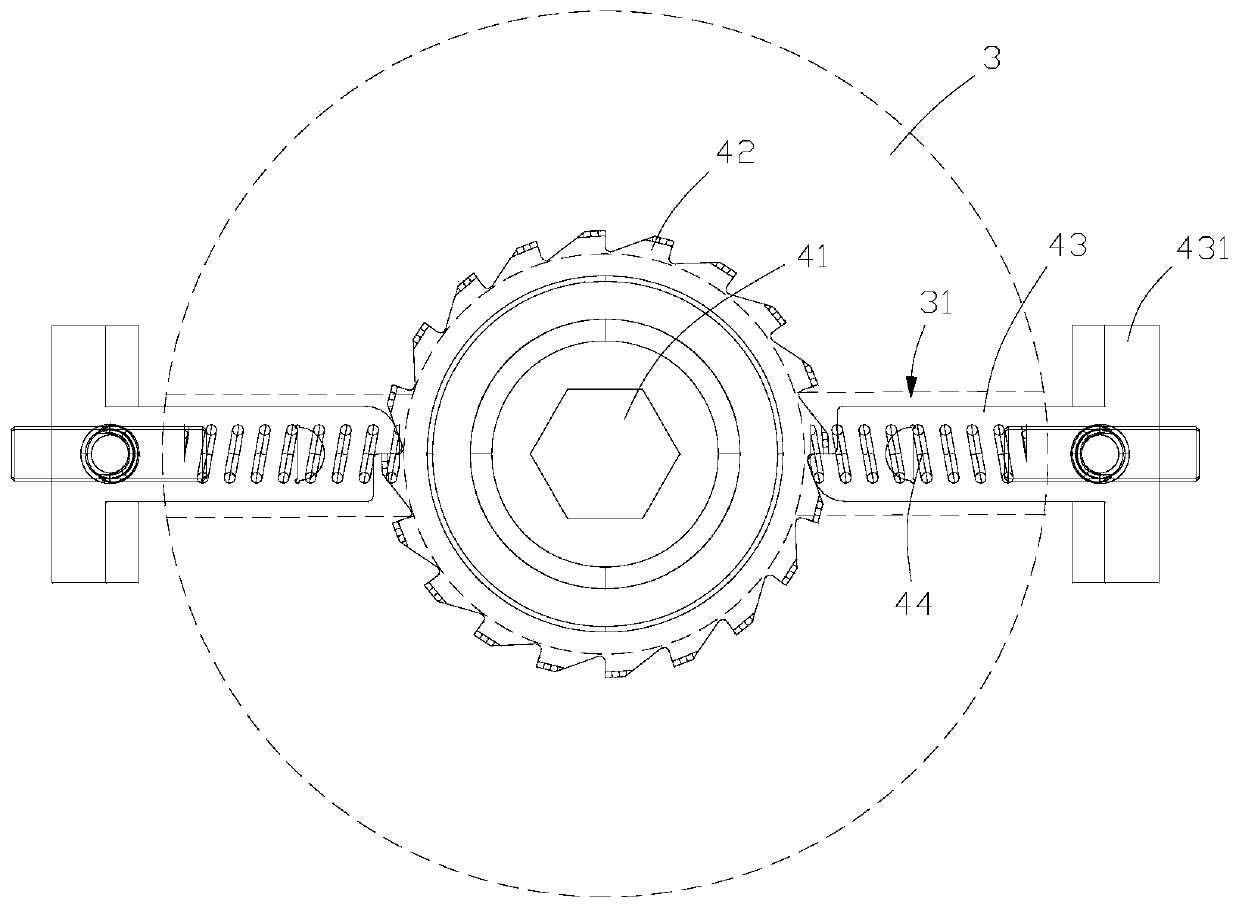

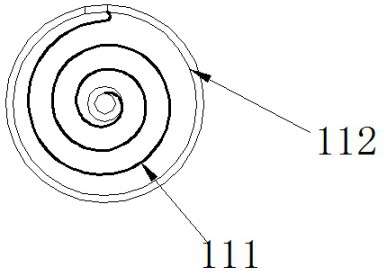

Stranding and combining all-in-one machine for producing 7*7 structural steel wire rope

ActiveCN114164691AAvoid interferenceSolve the transfer problemRope making machinesWire ropeManufacturing engineering

The invention relates to a rope stranding and combining all-in-one machine for producing a 7 * 7 structural steel wire rope. According to the stranding and stranding all-in-one machine, the stranding process and the stranding process in steel wire rope production are completed on the same machine at the same time, so that the working characteristics of a tubular stranding machine in the stranding process and a basket type stranding machine in the stranding process are combined, and a design scheme of the stranding and stranding all-in-one machine for producing 7 * 7 structural steel wire ropes is provided. According to the scheme, a pipe type stranding machine is derived into stranding pipes, a basket type rope combining machine is derived into a revolution disc, the stranding pipes rotate to drive seven steel wires on the stranding pipes to be stranded, the revolution disc revolves to drive the seven stranding pipes on the revolution disc to revolve to combine ropes, and therefore the 7 * 7 structural steel wire rope is produced.

Owner:河间市永兴通讯器材有限公司

Drum-type grinding device and grinding equipment

ActiveCN110270921AWon't fly outReduce dependencyEdge grinding machinesPolishing machinesEngineeringManipulator

The invention belongs to the technical field of grinding equipment, and particularly relates to a drum-type grinding device and grinding equipment. The drum-type grinding device comprises a drum and a cover body, wherein the cover body detachably hermetically covers the drum; a rotatable screw rod is arranged on the upper side of the cover body; rotatable guide rods are separately arranged on two opposite sides of the screw rod; a nut seat is arranged on the screw rod; a first connecting rod is arranged between the nut seat and the guide rod on each side; one end of each first connecting rod is hinged to the nut seat; a second connecting rod is fixedly arranged on each guide rod; the other end of each first connecting rod is hinged to the corresponding second connecting rod; lock hooks extending to one side of the drum are separately arranged at two ends of each guide rod; hook claws are arranged at parts, between the guide rods on two sides, on sides of the drum; and the screw rod is selectively rotated clockwise or anticlockwise to drive the nut seat to move in the axial line of the screw rod, and the lock hooks are driven by the guide rods to rotate, so that the lock hooks are locked with catches in a matching manner, or the lock hooks are separated from the hook claws to realize unlocking. The unlocking can be realized by a manipulator, the degree of automation is high, the production efficiency is improved, and time and labor are saved.

Owner:广东顺德三扬科技股份有限公司

Aluminum profile cutting device for producing automobile motor shell

ActiveCN113146338AWon't fly outImprove sound insulationMetal sawing devicesMaintainance and safety accessoriesClassical mechanicsEngineering

The invention discloses an aluminum profile cutting device for producing an automobile motor shell. The device comprises a supporting table, supporting columns are fixedly installed in the middles of the left end and the right end of the supporting table, sliding grooves are formed in the opposite faces of the two supporting columns, and a supporting frame is jointly and fixedly installed at the upper ends of the two supporting columns. Three telescopic rods distributed at equal intervals are fixedly installed at the lower end of the supporting frame. According to the aluminum profile cutting device, through the arranged sound reduction assembly, an extrusion plate can drive a mounting box to move downwards while moving downwards, the mounting box drives a sound insulation block to extrude aluminum profiles downwards, the downward moving distances of the sound insulation block are different due to different shapes of the aluminum profiles, and the sound insulation block pushes a sliding rod to slide in a round hole and extrudes a spring to stretch out and draw back. The sound insulation block can be attached to the aluminum profile needing to be cut, it is guaranteed that no chippings fly out, the good sound insulation effect is achieved, and the aluminum profile cutting device can be suitable for aluminum profiles of different shapes.

Owner:FUAN XINRUI MACHINERY CO LTD

Hydraulic engineering concrete quality detection device

PendingCN112082871AReduce laborImprove detection efficiencyMaterial strength using tensile/compressive forcesHydraulic cylinderArchitectural engineering

The invention discloses a hydraulic engineering concrete quality detection device which comprises a base, four supporting columns are fixedly connected to the upper end of the base, a supporting plateis fixedly connected to the upper ends of the four supporting columns jointly, and two first hydraulic cylinders are fixedly connected to the bottom of the supporting plate. The output ends of the two first hydraulic cylinders are jointly and fixedly connected with a U-shaped plate, a clamping mechanism is installed on the U-shaped plate, two second hydraulic cylinders are fixedly connected to the bottom of the supporting plate, the output ends of the two second hydraulic cylinders are jointly and fixedly connected with a pressure plate, and a protective cover is arranged on the outer side ofthe pressure plate; and a rubber layer matched with the protective cover is arranged on the inner wall of the protective cover. The device is reasonable in structure, concrete can be conveniently carried to or off the workbench, the workload of workers is reduced, the monitoring efficiency is improved, and damage to the protective cover can be reduced, replacement of the protective cover is reduced, and economic losses are reduced under the condition that sand and stone are prevented from flying out and hurting people.

Owner:赵政恒

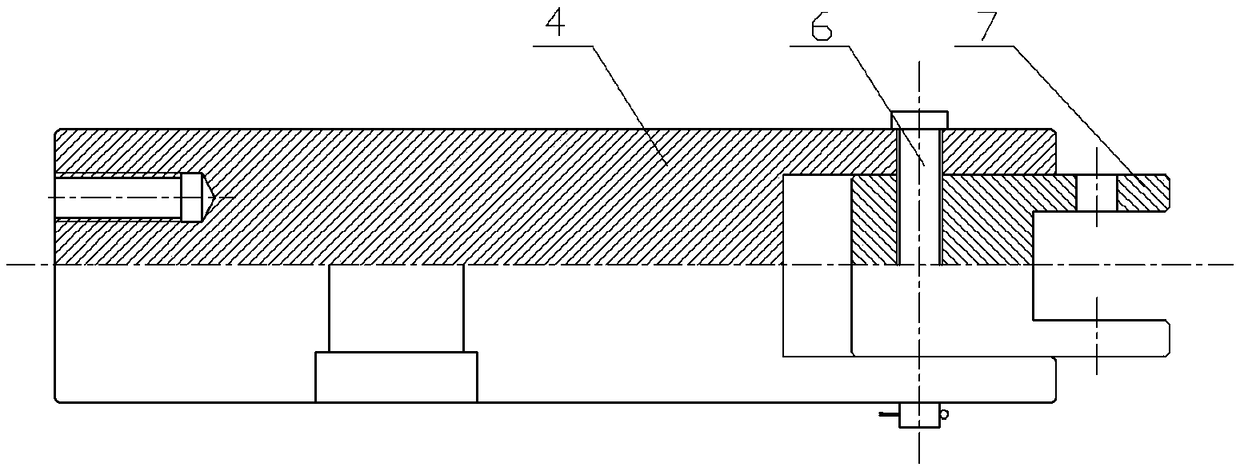

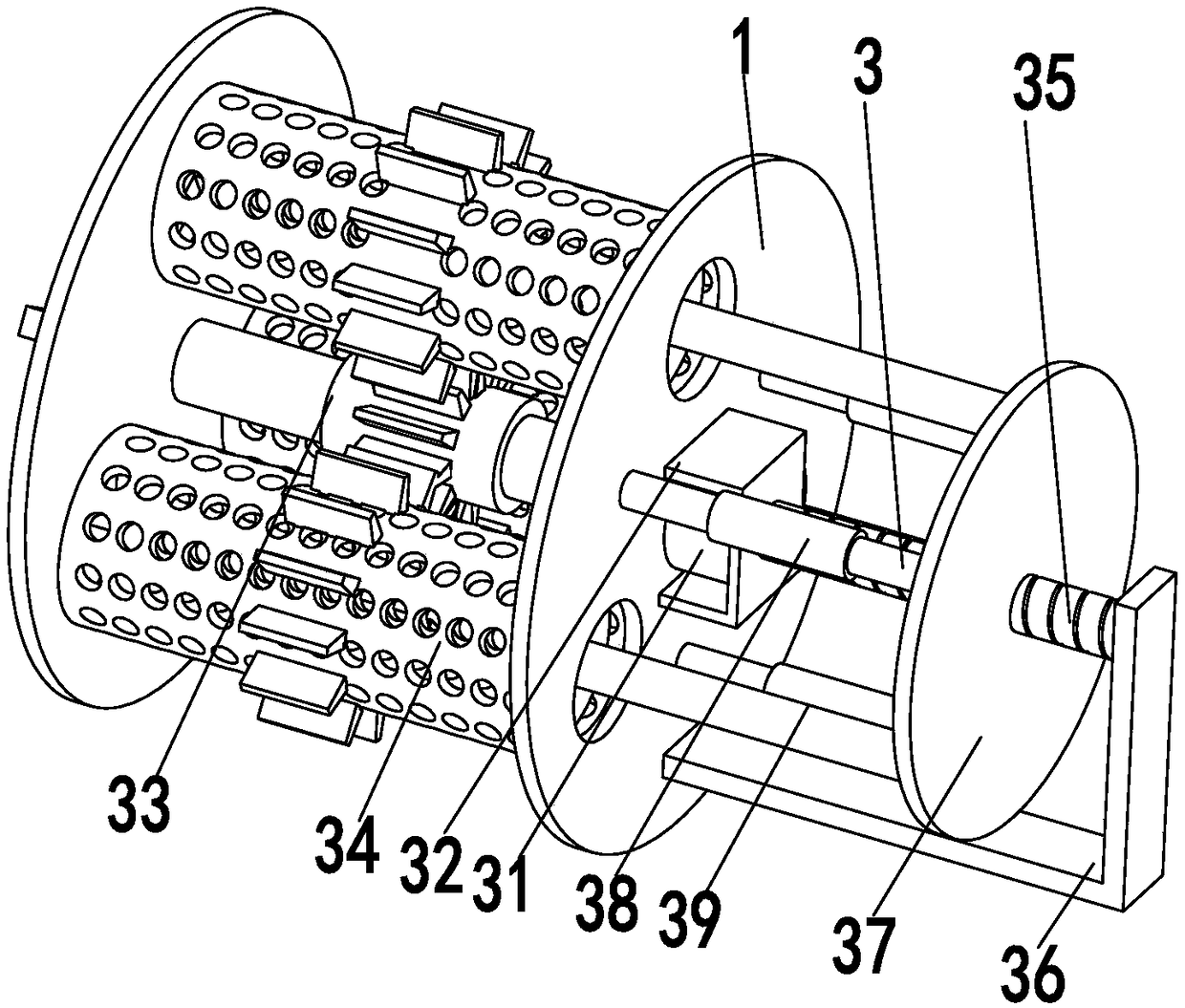

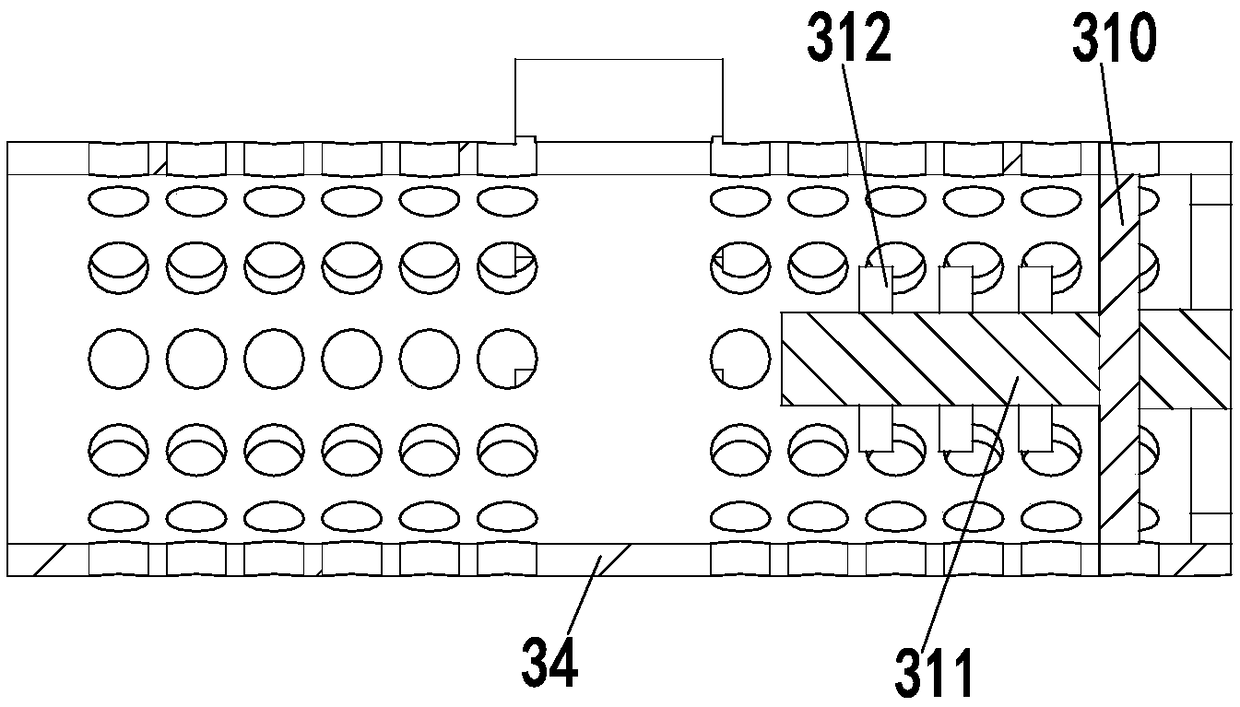

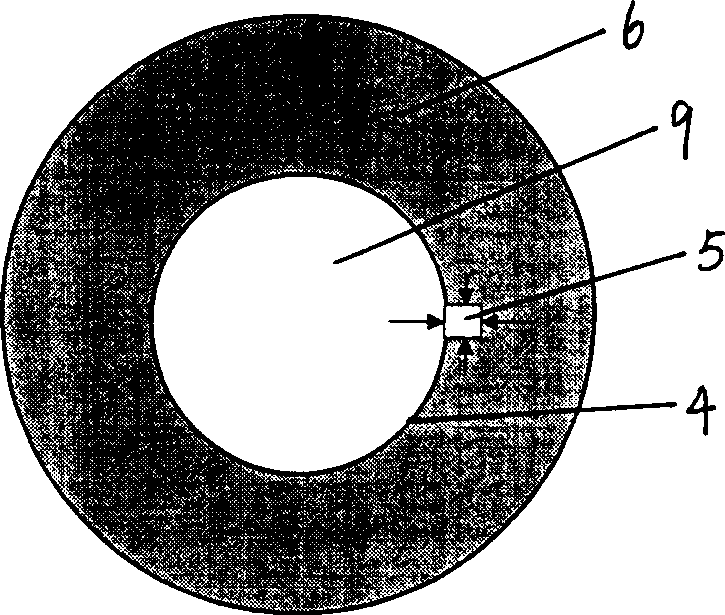

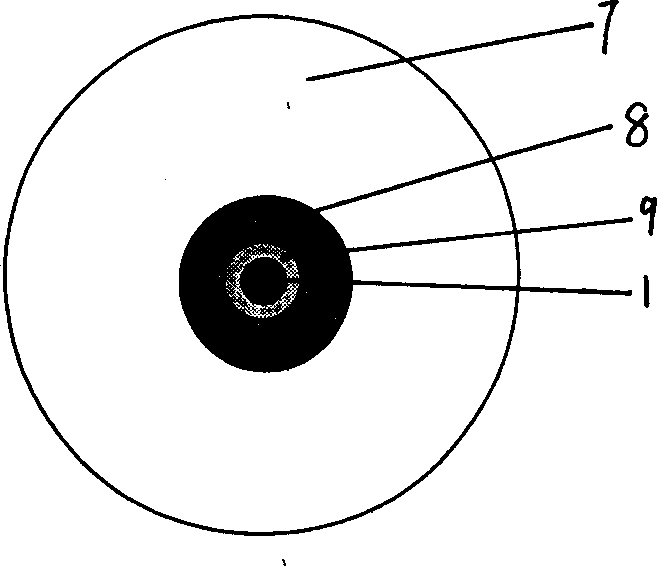

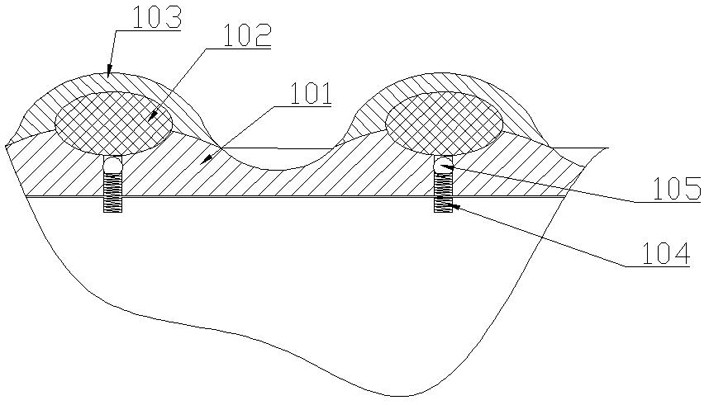

Bonding protection tool and protection pasting method for rotor magnetic steel of permanent magnet motor

ActiveCN110492703APrevent flying outGuarantee the safety of lifeManufacturing stator/rotor bodiesPermanent magnet motorUltimate tensile strength

The invention discloses a bonding protection tool and a bonding protection method for rotor magnetic steel of a permanent magnet motor, solving the problem that in the prior art, when rotor magnetic steel is assembled, bonded magnetic steel easily repels the magnetic steel which is being assembled to fly out. A sleeve (5) movably sleeves a rotating shaft (1); the sleeve (5) rotates around the rotating shaft (1) by taking the rotating shaft (1) as a central axis; a rotor core (2) is arranged in the sleeve (5); a magnetic steel assembling window (6) is arranged on the cylindrical side surface ofthe sleeve (5); bonded magnetic steel (3) is arranged on the outer surface of the right end of the rotor core (2) in the magnetic steel assembly window (6); magnetic steel (4) being assembled is arranged on the left side of the bonded magnetic steel (3) in the magnetic steel assembly window (6); and a magnetic steel assembly push rod (9) is movably inserted into a magnetic steel assembly push rodinsertion through hole (8). The personal safety of assembly personnel is ensured, and the working intensity of magnetic steel attachment is also reduced.

Owner:CSIC ELECTRICAL MACHINERY SCI & TECH

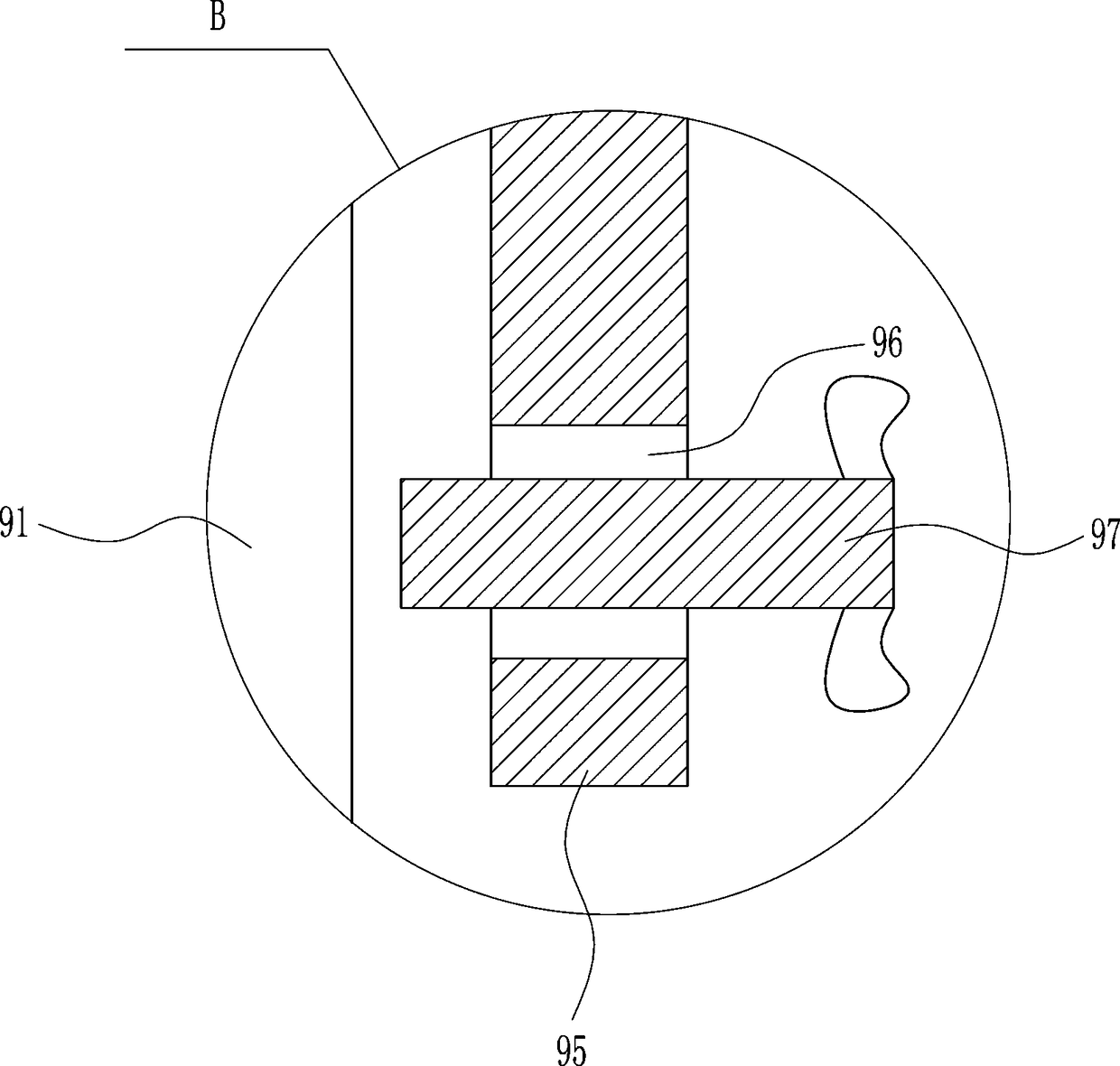

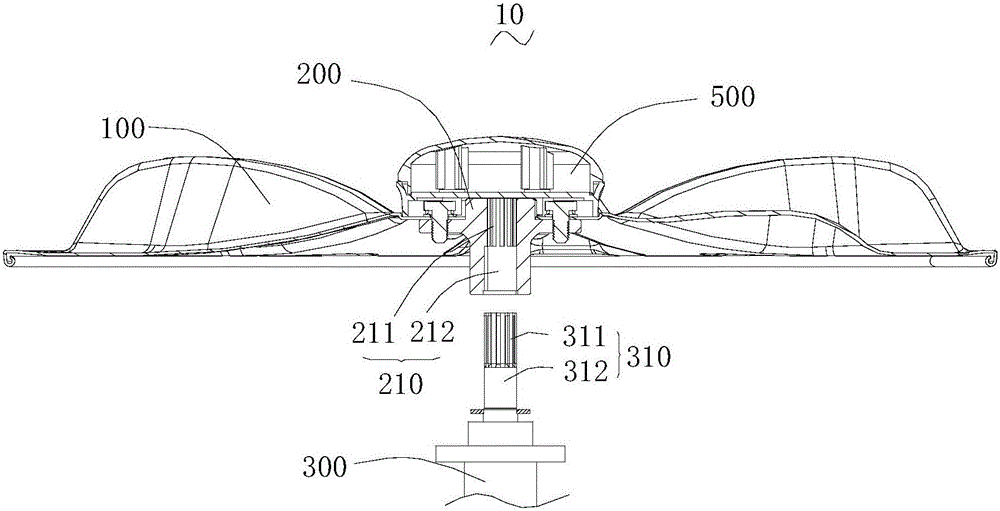

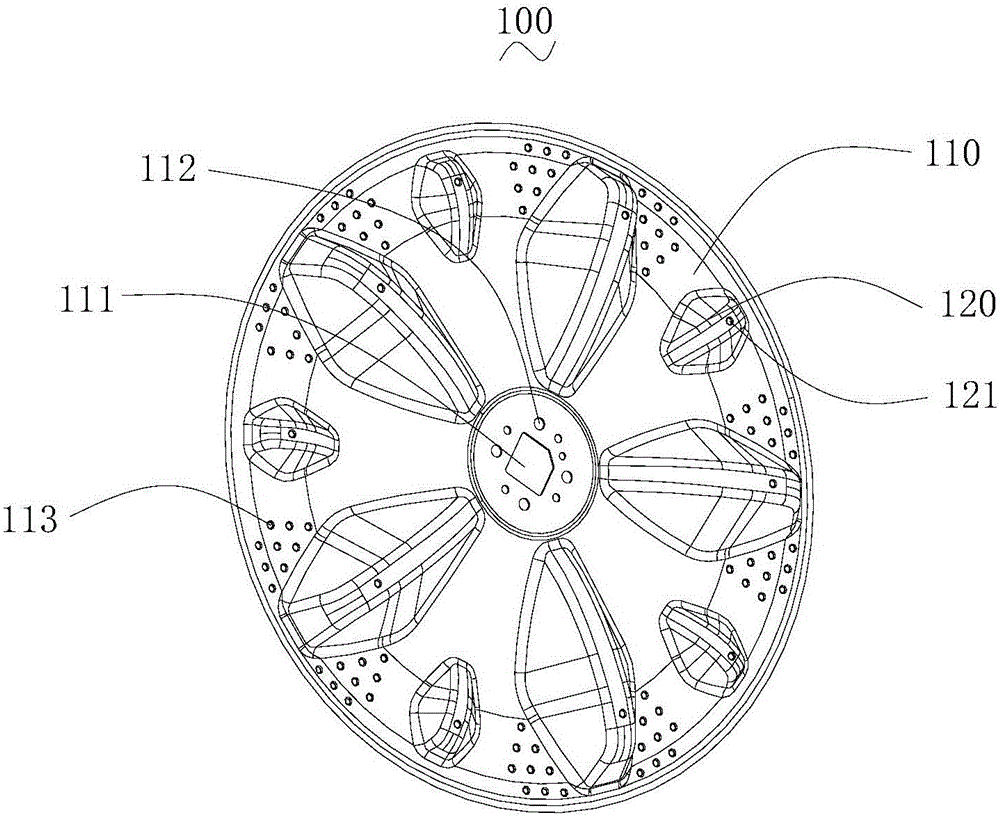

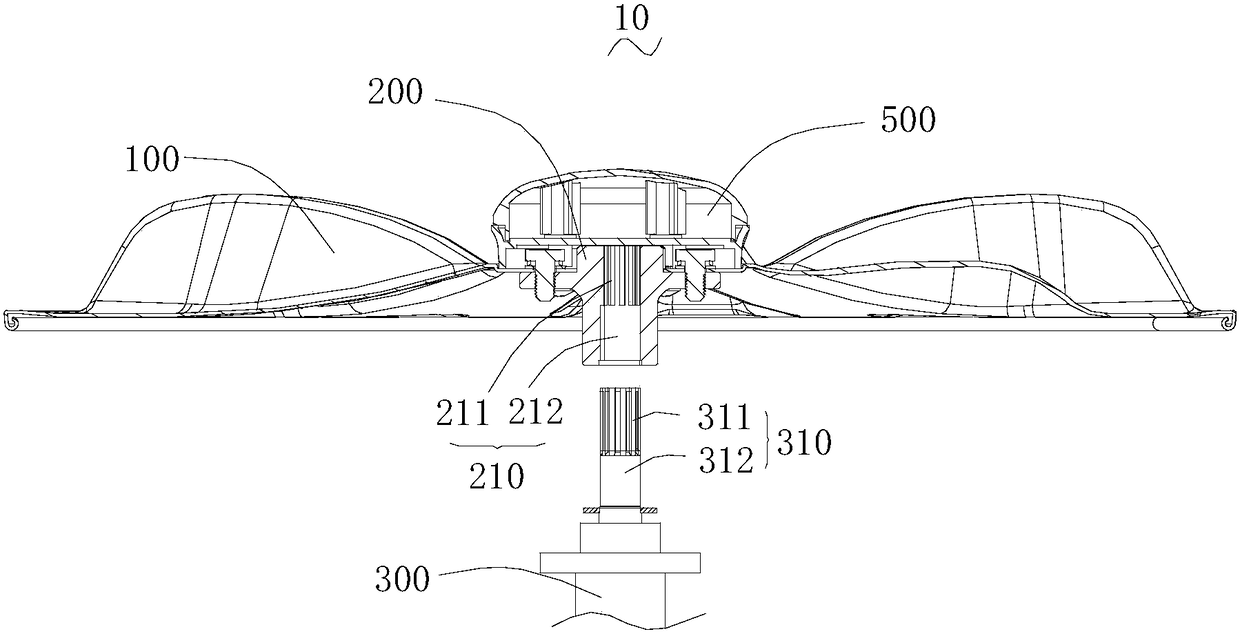

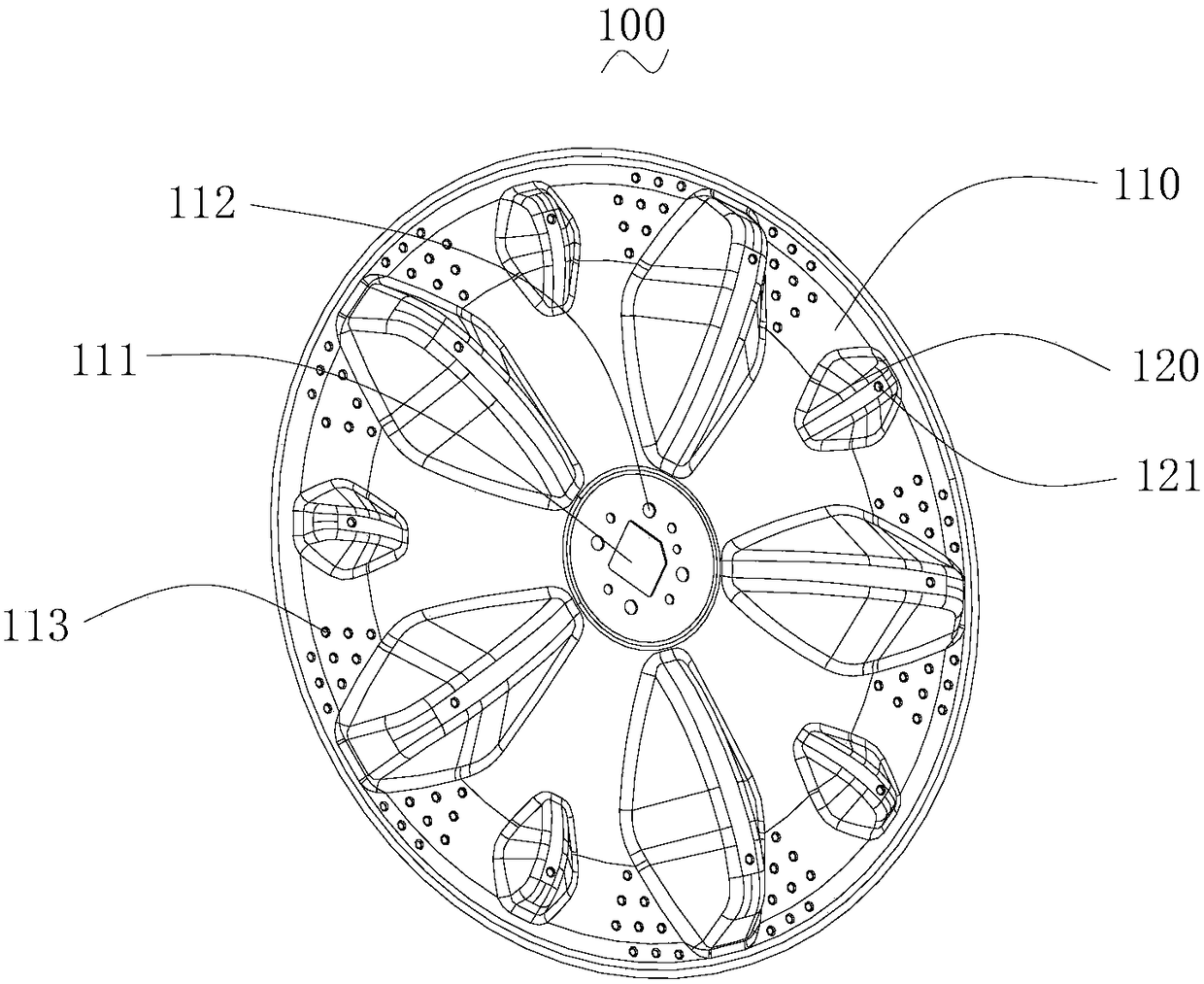

Impeller connecting assembly and washing machine applying impeller connecting assembly

ActiveCN105887407AWon't fly outEasy to useWashing machine with receptaclesTextiles and paperImpellerEngineering

The invention relates to an impeller connecting assembly and a washing machine. The impeller assembly comprises an impeller, a connecting piece and a deceleration assembly, wherein the connecting piece is arranged on the impeller; the deceleration assembly is arranged on the connecting piece; an installation hole for connecting the deceleration assembly is formed in the connecting piece; the installation hole comprises a first zone and a second zone; a washing shaft of the deceleration assembly penetrates through the installation hole; the washing shaft is provided with a first connecting part and a second connecting part which are connected in sequence; the first connecting part is matched with the first zone and penetrates through the first zone; the second connecting part is matched with the second zone and penetrates through the second zone; the matching tightness between the first zone and the first connecting part is smaller than that between the second zone and the second connecting part. According to the impeller assembly disclosed by the invention, disassembly and assembly can be simplified, the disassembly efficiency and the assembly efficiency can be increased, and convenience is provided for a user to use.

Owner:TCL HOME APPLIANCES (HEFEI) CO LTD

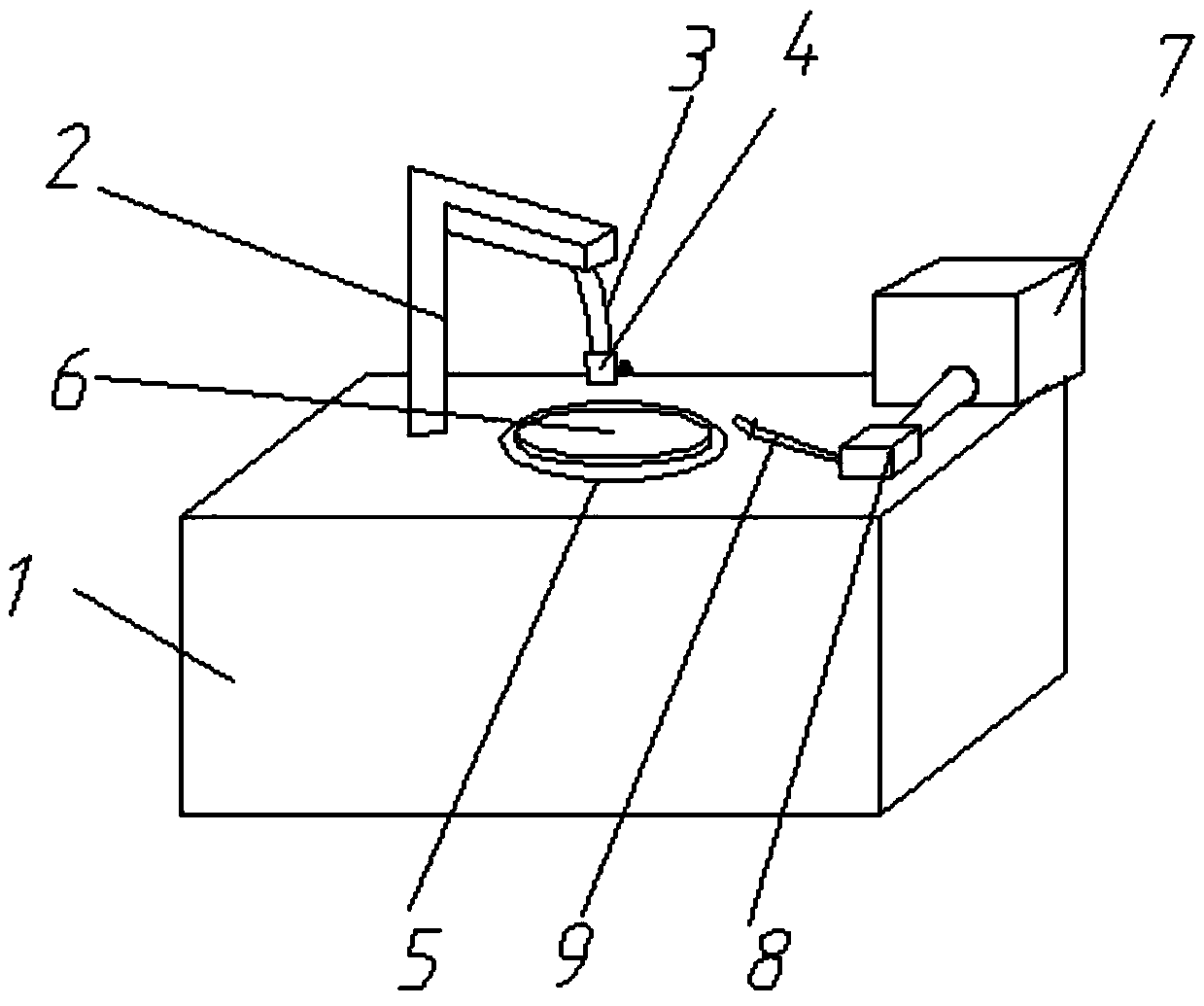

Device for polishing metallographic experimental sample

InactiveCN109342158AWon't fly outImprove securityPreparing sample for investigationLocking mechanismEngineering

The invention discloses a device for polishing a metallographic experimental sample. A support rod is arranged on the upper surface of a base, the support rod totally comprises two sections, the top end of a vertical section is connected with the leftmost side of a horizontal section, and an elastic hard connecting rod is fixedly connected to the bottom of the rightmost side of the horizontal section, and made of an elastic material, so that the shape of the elastic hard connecting rod can be changed and the form of the elastic hard connecting rod can be kept while not subjected to force; a sample locking mechanism is connected to the bottom of the elastic hard connecting rod, a circular groove is formed in the upper surface of the base and beside the support rod, a circular grinding discof which the diameter is smaller than that of the groove is arranged concentrically in the groove, and the grinding disc is driven to rotate through a motor; a water tank is arranged on the base, andthe water tank pumps cooling water out from the water tank through a water pump, and a water pipe is drained, thereby being capable of cooling the surface of the grinding disc. The safety of the sample using the device disclosed by the invention can be effectively improved, and the sample does not fly out; in addition, the polishing efficiency is further improved.

Owner:徐州大正东智机械科技有限公司

Cotton carding device for HY cellucotton

ActiveCN112442764AAvoid cloggingTo achieve the effect of cleaning and absorptionCarding machinesAgricultural engineeringMechanical engineering

The invention relates to the technical field of cotton carding, and discloses a cotton carding device for HY cellucotton. The cotton carding device comprises a machine body; a licker-in is rotatably connected into the machine body; a cylinder is rotatably connected to the portion, located on the right side of the licker-in, of the machine body; a doffer is rotatably connected to the portion, located on the right side of the cylinder, of the machine body; a cover plate set is connected to the top of the machine body through bolts; a feeding table is connected to the front portion of the machinebody through bolts; a pressing roller is rotatably connected to the surface of the feeding table; an auxiliary cotton carding mechanism is arranged in the feeding table; and a baffle is welded to thesurface of the feeding table. According to the cotton carding device for the HY cellucotton, the auxiliary cotton carding mechanism is used for achieving the effects of cleaning the surface of the licker-in and secondarily recycling carded cotton, the effects of loosening and evenly distributing auxiliary cotton before cotton carding are achieved, and the problem that the cotton is blocked in thecotton carding process due to uneven distribution of the auxiliary cotton is solved; and the effect of cleaning and absorbing scattered cellucotton while the cover plate set performs cotton carding on the cellucotton is achieved.

Owner:德清宏业晶体纤维有限公司

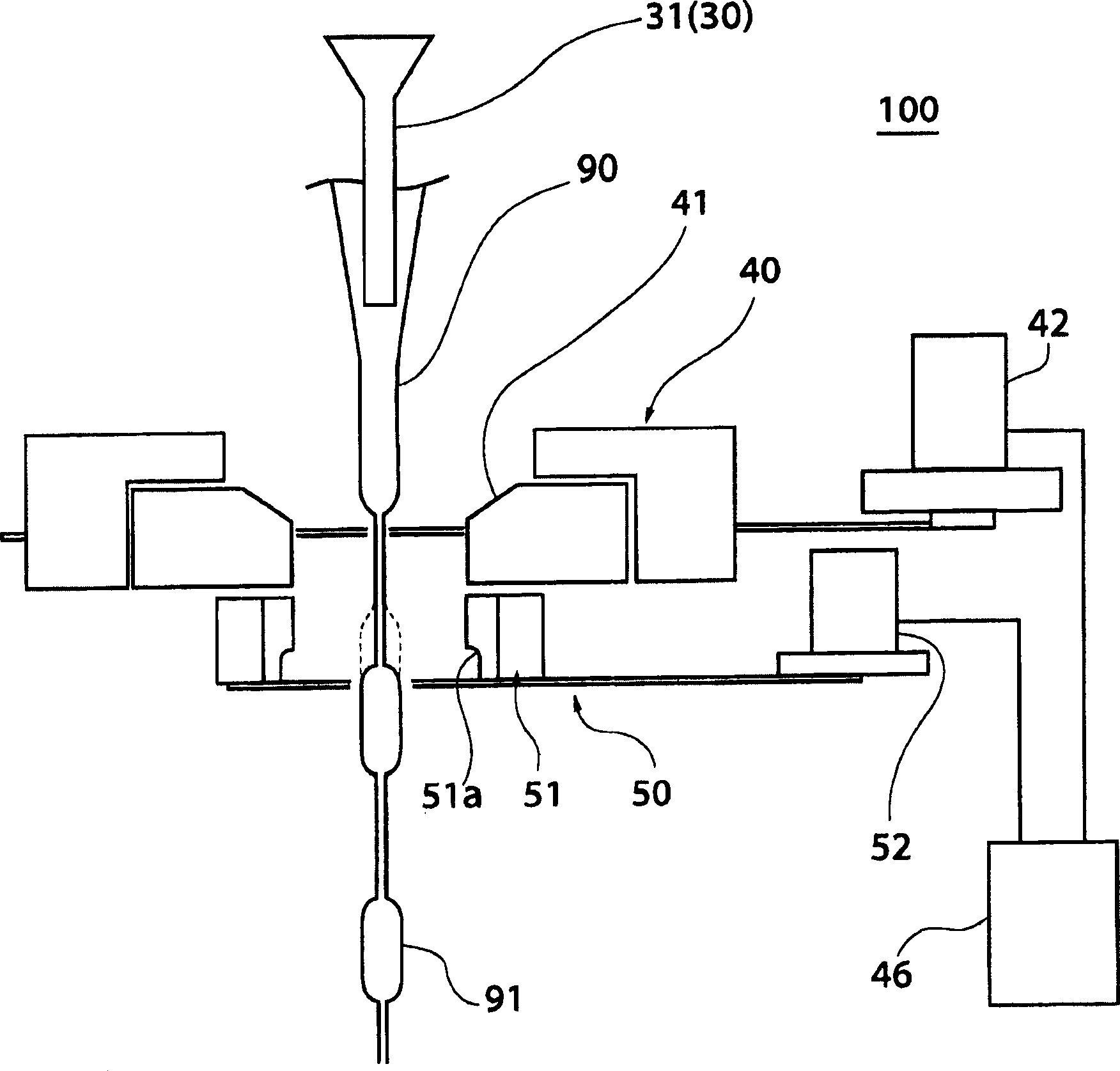

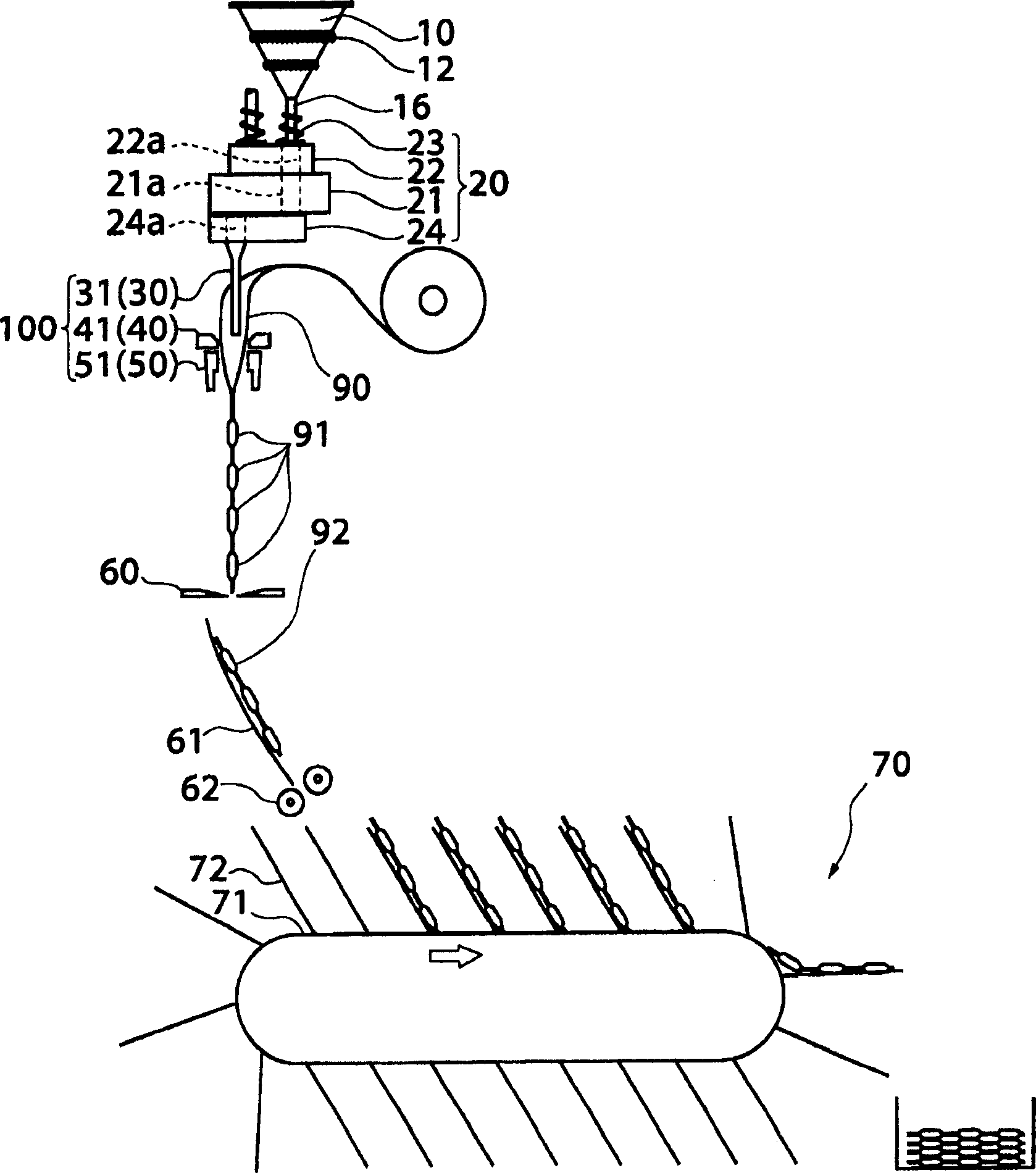

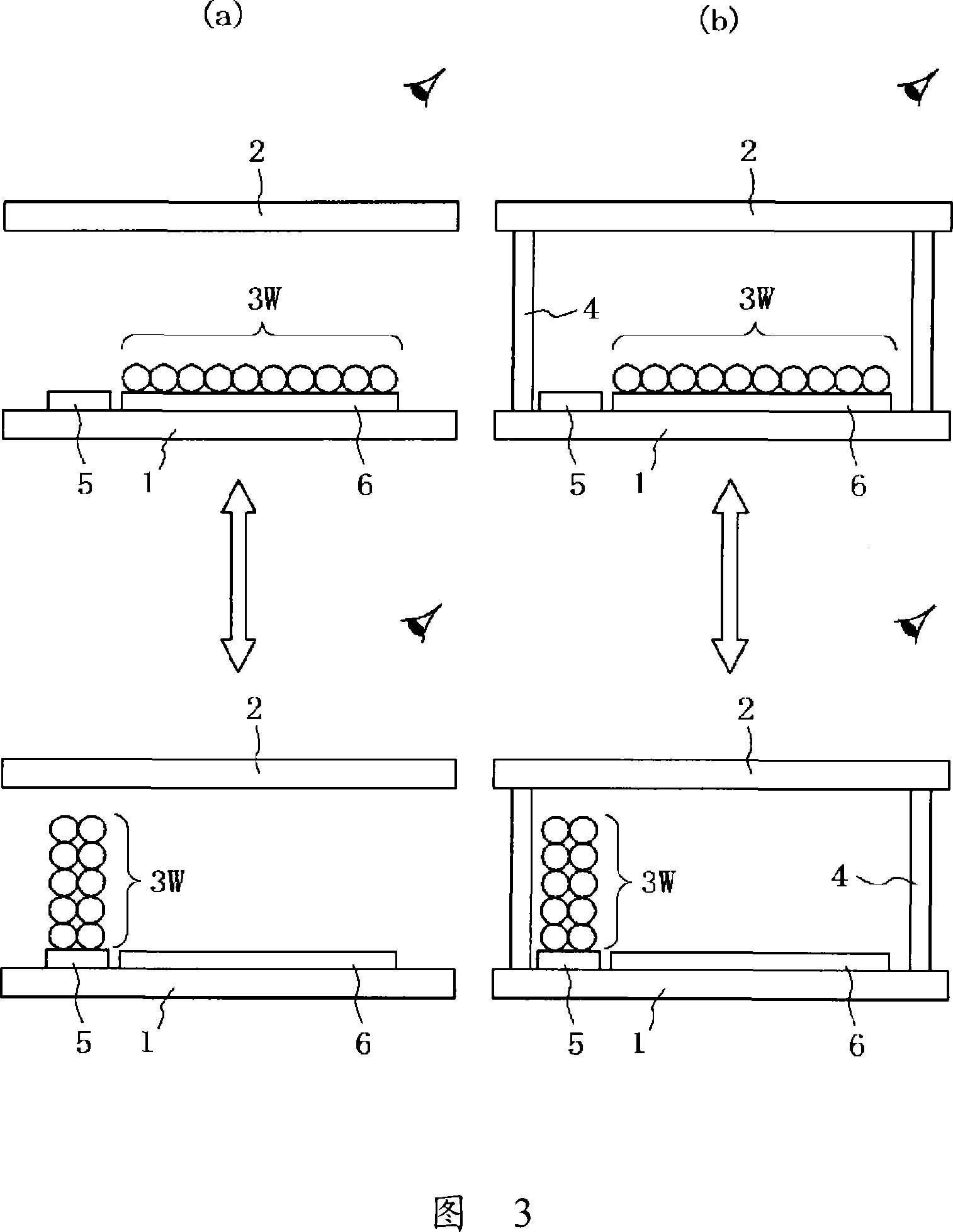

Packaging device, measuring and packaging device, and method of manufacturing packaged article

InactiveCN1842469AWon't fly outInhibit swellingPackaging by pressurising/gasifyingWrapper twisting/gatheringEngineeringMechanical engineering

Owner:KUREHA KAGAKU KOGYO KK

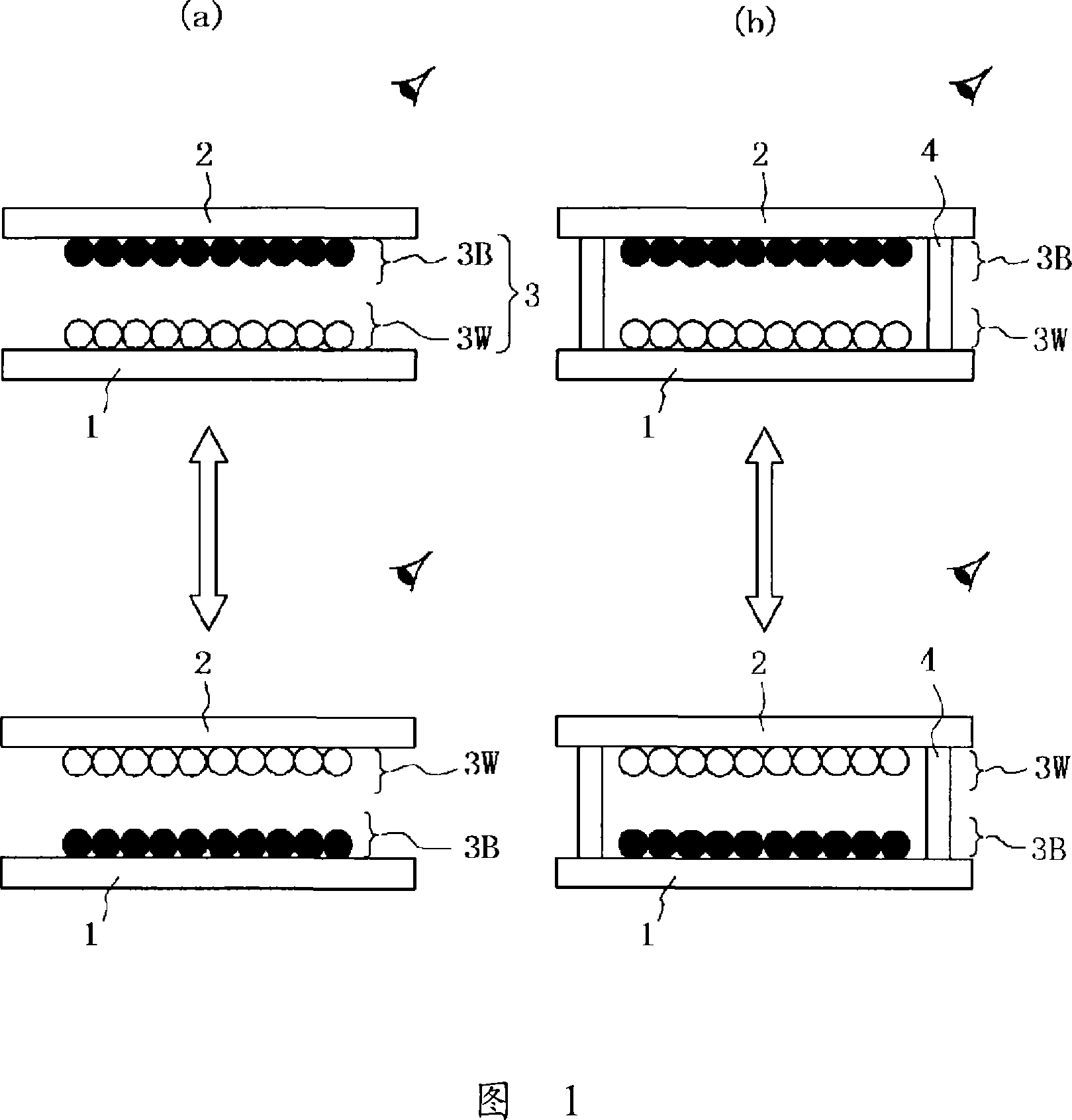

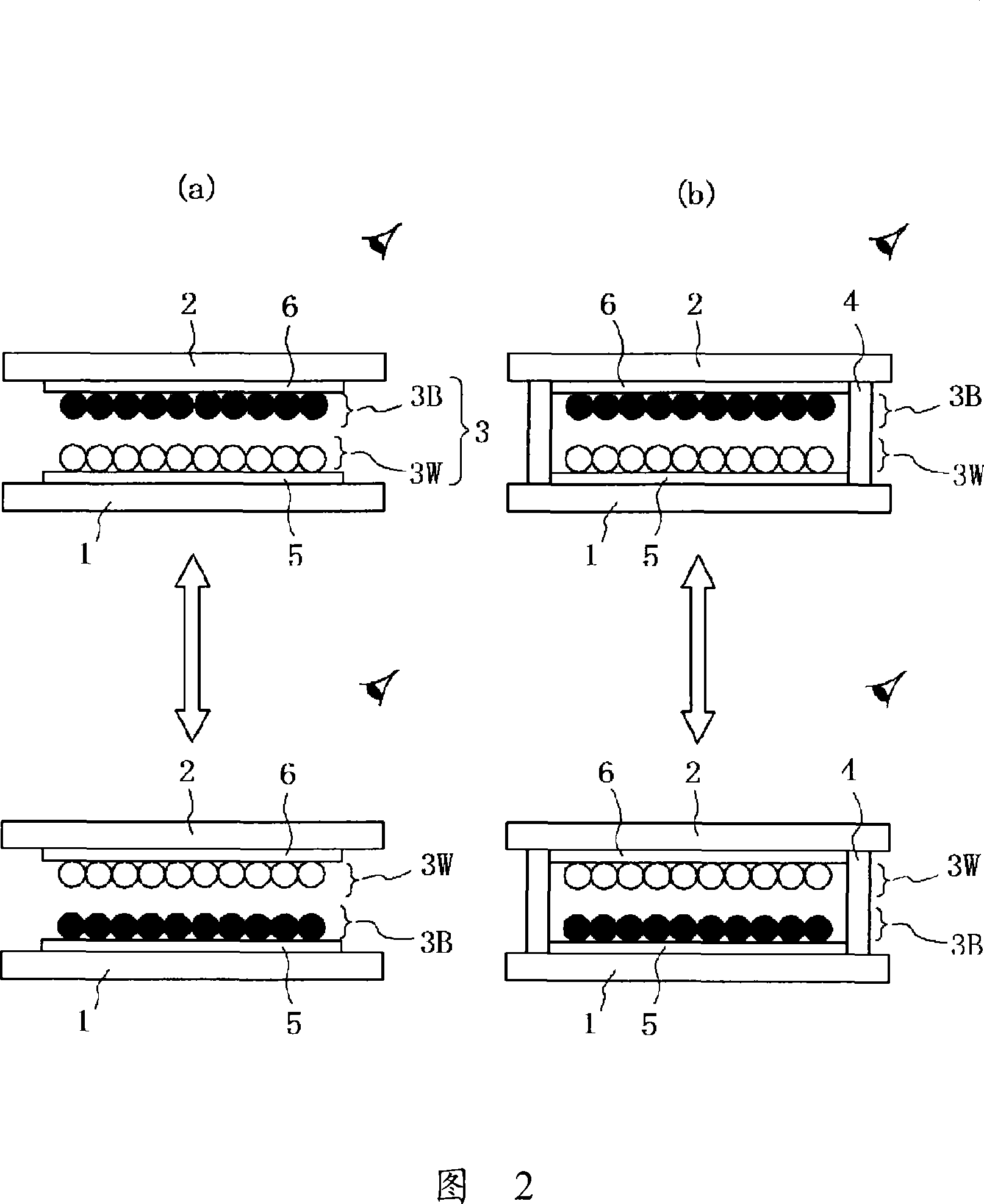

Method for manufacturing information display panel

Owner:BRIDGESTONE CORP

Wood board cutting chip prevention device for decoration

PendingCN113400426AEasy to adjustEasy maintenance and operationBark-zones/chip/dust/waste removalWood working safety devicesMechanical engineeringWood plank

The invention discloses a wood board cutting chip prevention device for decoration. The device comprises a protective mounting base, an inner shell is fixedly connected to the outer wall of the top of the protective mounting base, an inner turning plate is slidably connected to the outer wall of the inner shell, limiting sliding grooves are formed in the outer walls of the bottom ends of the two sides of the inner shell, the inner shell is slidably connected with an outer shell through the limiting sliding grooves, and the outer wall of the outer shell is slidably connected with an outer turning plate. The device is of a full-wrapping type structure, one side of the device is a sliding opening side, internal wood boards can be conveniently adjusted, or cutting equipment can be conveniently subjected to maintenance operation, the sliding opening end is associated with the cutting equipment, when the cutting equipment is started, the sliding opening end is closed through a driving assembly, full-wrapping closing is achieved, meanwhile, a chip suction assembly on the lower side can adsorb and collect chips generated after wood boards are cut, the safety during wood board cutting is guaranteed, and meanwhile chips generated during cutting are prevented from splashing.

Owner:安徽森通建设工程有限公司

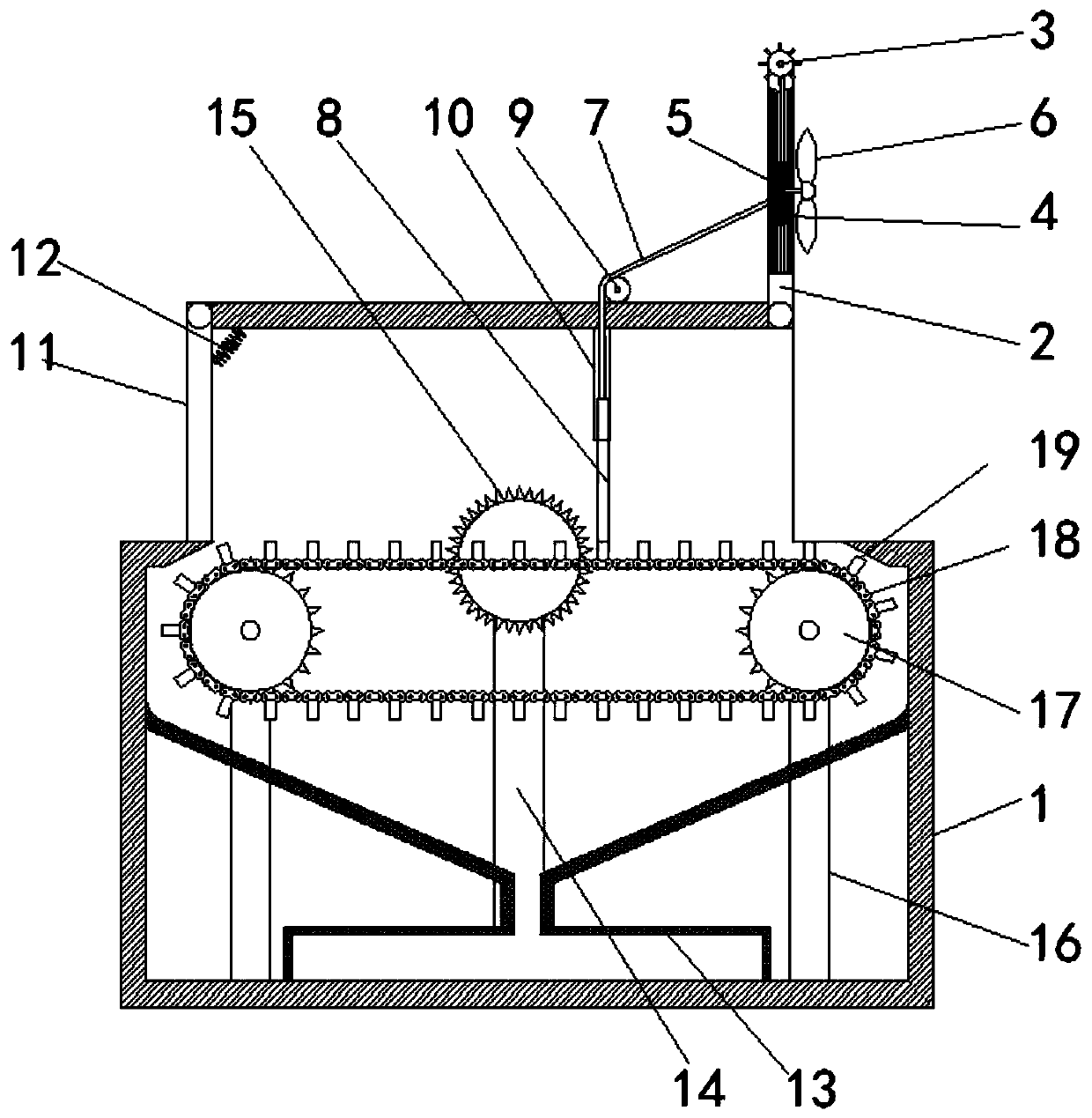

Wood processing cutting machine capable of collecting wood dust based on chain drive

The invention relates to the technical field of wood processing and discloses a wood processing cutting machine capable of collecting wood dust based on chain drive. The wood processing cutting machine comprises a case; a feeding door is movably connected with the right side of the top of the case; a ratchet wheel is fixedly connected with the top of the feeding door; a worm is meshed with the back of the ratchet wheel; a turbine is meshed with the middle of the worm; a fan is fixedly connected with the right side of the turbine; a connecting rope is fixedly connected with the left side of thefeeding door; a chain wheel bracket is fixedly connected with the inner bottom of the case; a chain wheel is fixedly connected with the top of the chain wheel bracket; a carry chain is meshed with the outer side of the chain wheel; and a catch pawl is fixedly connected with the outer side of the carry chain. According to the wood processing cutting machine, a motor drives the chain wheel to rotate, the chain wheel drives the carry chain to rotate, the carry chain drives the catch pawl to rotate, and then through cooperative application of the catch pawl and a collecting shell, the effect of automatically collecting the wood dust is realized.

Owner:朱彩云

A pulsator connection assembly and a washing machine using the pulsator connection assembly

ActiveCN105887407BWon't fly outEasy to useWashing machine with receptaclesTextiles and paperImpeller

The invention relates to an impeller connecting assembly and a washing machine. The impeller assembly comprises an impeller, a connecting piece and a deceleration assembly, wherein the connecting piece is arranged on the impeller; the deceleration assembly is arranged on the connecting piece; an installation hole for connecting the deceleration assembly is formed in the connecting piece; the installation hole comprises a first zone and a second zone; a washing shaft of the deceleration assembly penetrates through the installation hole; the washing shaft is provided with a first connecting part and a second connecting part which are connected in sequence; the first connecting part is matched with the first zone and penetrates through the first zone; the second connecting part is matched with the second zone and penetrates through the second zone; the matching tightness between the first zone and the first connecting part is smaller than that between the second zone and the second connecting part. According to the impeller assembly disclosed by the invention, disassembly and assembly can be simplified, the disassembly efficiency and the assembly efficiency can be increased, and convenience is provided for a user to use.

Owner:TCL HOME APPLIANCES (HEFEI) CO LTD

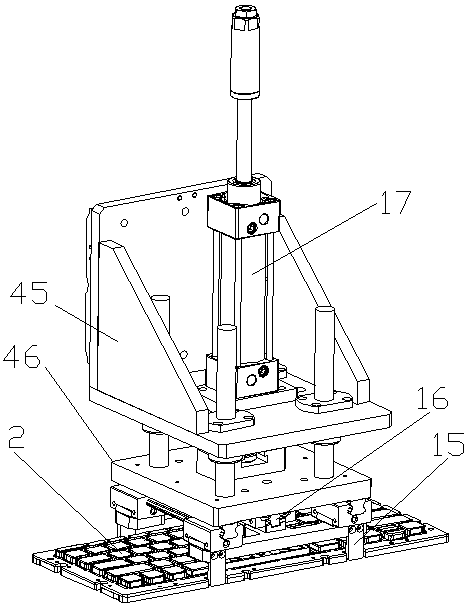

Tooling for rough turning of constant velocity universal joint bell shell

ActiveCN111185778BConvenient rough carStop shakingWork clamping meansPositioning apparatusMotor vehicle partUniversal joint

The invention relates to the field of automobile part manufacturing, in particular to a constant velocity universal joint bell housing rough turning tool. The constant velocity universal joint bell housing rough turning tool comprises a bottom anti-rotation assembly, a supporting bottom plate, a first annular face clamping assembly, a second annular face clamping assembly, a first end face pressing assembly and a second end face pressing assembly, the bottom anti-rotation assembly is located at the bottom of the supporting bottom plate, the first annular face clamping assembly and the second annular face clamping assembly are both located at the top of the supporting bottom plate, the first end face pressing assembly and the second end face pressing assembly are both located at the top ofthe supporting bottom plate, and the first end face pressing assembly and the second end face pressing assembly are both located at the top of the supporting bottom plate. According to the constant velocity universal joint bell housing rough turning tool, the lower ring column of the bell housing can be clamped and prevented from shaking, a layer of insurance can be provided for fixation of the bell housing, and the bell housing cannot rotate during machining.

Owner:石娟娟

A circuit board production device

ActiveCN108495473BWon't fly outIncrease etch rateConductive material chemical/electrolytical removalSlide plateConductive materials

The invention relates to the technical field of removing conductive materials by a chemical or electrolytic method, especially to a circuit board production apparatus comprising an etching box and a covering part. The covering part consists of an annular ring and a cover plate arranged at the center of the annular ring; and connecting rods are connected between the cover plate and the annular ringand an exhausting hole is formed between each two adjacent connecting rods. A rotating plate that can cover the exhausting holes is connected between the annular ring and the cover plate in a rotation manner; and a torsion spring is arranged at the rotating plate. A placing part is arranged inside the etching box; an annular slot is formed in the inner wall of the etching box; a cavity is formedin the wall of the etching box; a connection cavity is communicated between the bottom of the annular slot and the cavity; a sliding plate is arranged in the connection cavity in a sliding connectionmanner; a pull rod is fixed at the sliding plate; and a protrusion is fixed at the annular ring. An L-shaped slot is formed in the inner wall of the etching box; and an elastic layer is arranged at the bottom of the L-shaped slot. Therefore, problems that the etching liquid is easy to splash out of the etching box at the stirring time and irritant gas can not be exhausted quickly in the etching box in the prior art can be solved.

Owner:曾广君

Vibration damping type skiing practice board

The invention discloses a vibration damping type skiing practice board, and relates to sports equipment, in particular to a practice board for training snowboarding. A snowboard body is composed of apanel, an upper aluminum alloy layer, an upper glass fiber cloth layer, a wooden board core, a lower aluminum alloy layer, a lower glass fiber cloth layer and a board bottom which are sequentially bonded from top to bottom, a strip-shaped steel plate is fixed to the center line of the upper surface of the wooden board core, and a steel edge blade is fixed to the edge of the board bottom; and the edge of the snowboard body is provided with an inwards-concave arc-shaped groove, the lower edge of the arc-shaped groove is located at the upper side of the lower glass fiber cloth layer, an annular vibration damping side wall is arranged in the arc-shaped groove in a surrounding mode, and the outer surface of the vibration damping side wall is in a smooth wave shape. The skiing practice board solves the problem that for skiing beginners, an existing snowboard cannot achieve the effect of reducing impact force of collision to protect the safety of skiing practicers.

Owner:HEILONGJIANG UNIV

Keyboard automatic disassembly cleaning machine

ActiveCN107737774BRealize fully automatic disassemblyImprove processing efficiencyCleaning using gasesSortingEngineeringConveyor belt

The invention discloses a full-automatic keyboard disassembling and cleaning machine. The machine comprises a control box, wherein a feeding device, a rotating disc device and a keycap detaching device and a keycap falling device are arranged on the table surface of the control box in sequence from one end to the other end; the feeding device comprises a feeding manipulator arranged on a first electric guide rail; a second electric guide rail is arranged between the keycap detaching device and the keycap falling device; a movable conveying manipulator is arranged on the second electric guide rail; an optical detector is arranged at the rear end of the control box; a third electric guide rail is arranged between the optical detector and the keycap falling device; the conveying manipulator is further arranged on the third electric guide rail; a conveyor belt is arranged below the optical detector; a stacking device is arranged at one end of the conveyor belt, and a dust collecting deviceand a discharging device are arranged at the other end; the discharging device comprises a fourth electric guide rail arranged above the conveyor belt; and a discharging manipulator is arranged on the fourth electric guide rail. The full-automatic keyboard disassembling and cleaning machine can realize full-automatic disassembling, cleaning and sorting of keyboards, thereby being high in automation degree and processing efficiency.

Owner:平邑县经发企业服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com