V-shaped grooving machine for pavement bending crack repairing construction

A technology for bending cracks and slotting machines, applied in road repair, roads, roads, etc., can solve the problems of caulking material falling off, loss of crack repair, etc., to reduce friction area, enhance cutting ability, and improve the effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

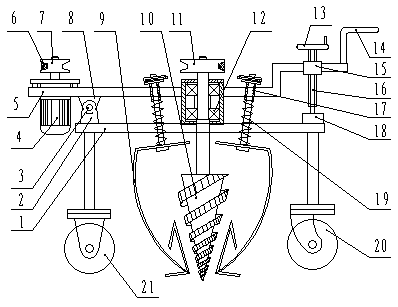

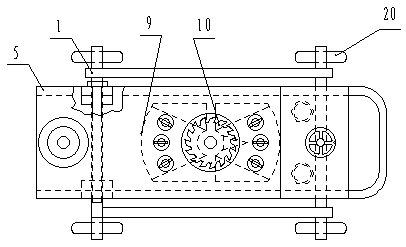

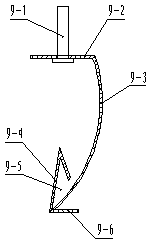

[0028] Example: in Figure 1-8 In the shown embodiment: a V-shaped slotting machine for road surface curved crack repair construction, including a lower frame 1, a winch shaft 3, an upper frame 5, a hand wheel 13, a screw 16, a motor 4, and a V-belt 6. Motor pulley 7, upper winch 8, dust collection device 9, slotter 10, slotted pulley 11, bearing 12, handrail 14, nut 15, guide sleeve 17, dust collection spring 19, lower winch 2 , screw seat 18, universal wheel 20, support ground wheel 21, described upper winch seat 8, dust collection device 9, lower winch seat 2, universal wheel 20, support ground wheel 21 are arranged in pairs, and motor 4 is installed on On the upper frame 5, the lower winch seat 2, the screw seat 18, the universal wheel 20, and the supporting ground wheel 21 are installed on the lower frame 1, and are provided with a plurality of paired guide sleeves 17, wherein the dust collection device 9 consists of a guide post 9-1, upper cover plate 9-2, dust collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com