Drum-type grinding device and grinding equipment

A grinding device and drum-type technology, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of lower production efficiency, general reliability, and poor automation, so as to improve production efficiency, reduce risks, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

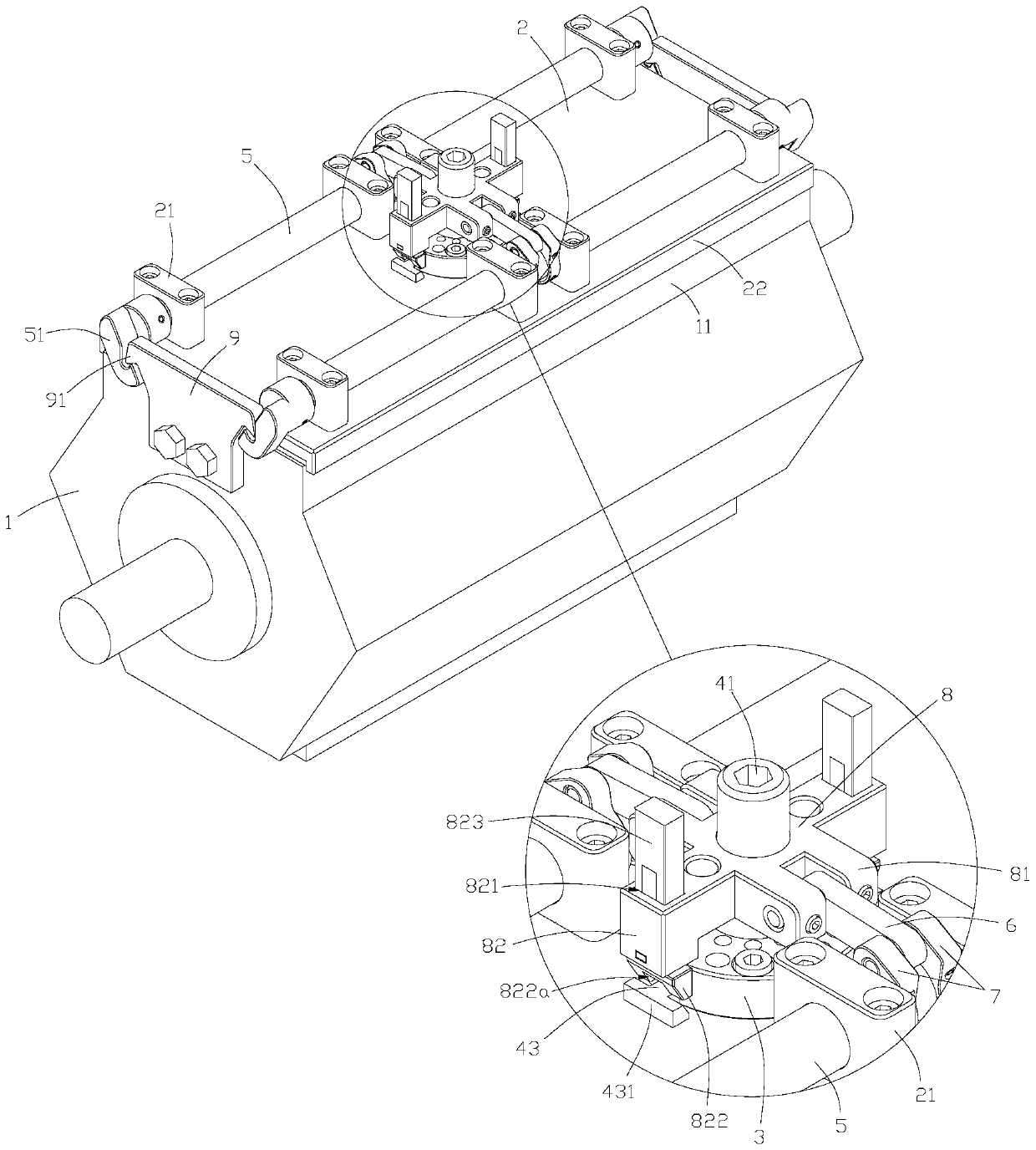

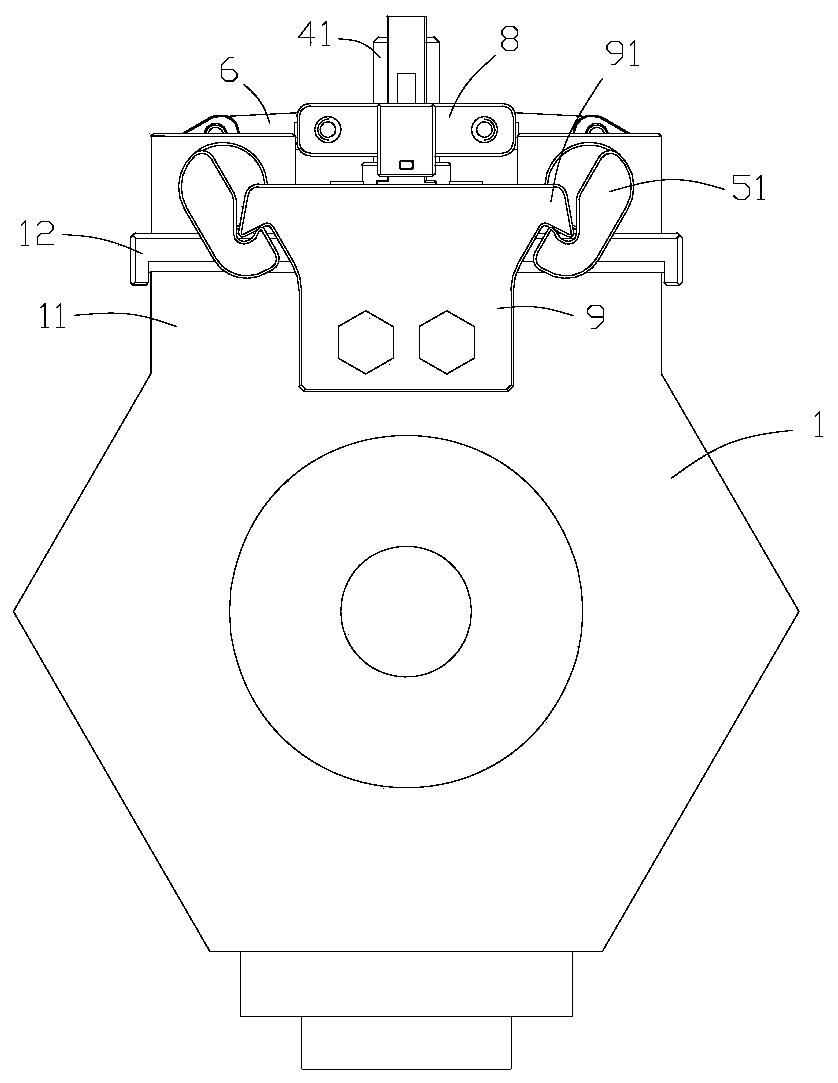

[0024] see figure 1 , figure 2 , Figure 4 and Figure 5 , this embodiment provides a drum grinding device, including a drum 1 and a cover 2, the drum 1 is provided with a grinding chamber, the outer wall of the drum 1 is provided with an opening communicating with the grinding chamber, and the cover 2 is detachable Cover the opening, preferably, the drum 1 is arranged in a prism structure, the outer periphery of the opening is provided with a convex edge 11 extending upward, the cover body 2 is set on the convex edge 11, and the drum 1 Setting it as a prism structure can effectively improve the friction effect of the workpiece in the grinding chamber, thereby improving the grinding effect.

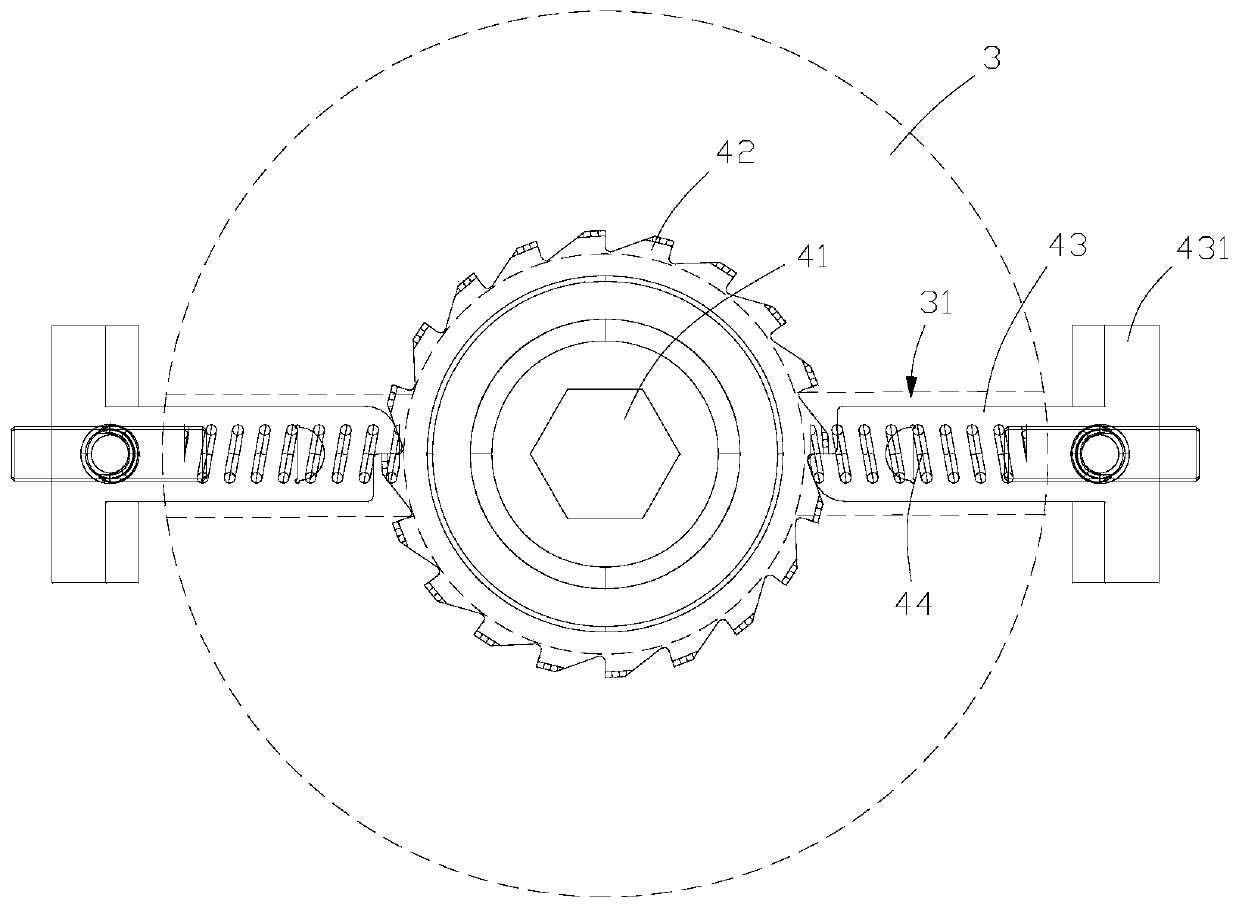

[0025] see figure 1 , figure 2 , Figure 4 and Figure 5 , the upper middle part of the cover body 2 is provided with a fixed seat 3, and the fixed seat 3 is provided with a screw rod 41 longitudinally, and the screw rod 41 can rotate around its axis relative to the cover body 2,...

Embodiment 2

[0032] Embodiment two (not shown in the figure of this embodiment):

[0033] This embodiment provides a grinding device using the grinding device of the first embodiment above, which includes the above-mentioned drum grinding device, a frame and a manipulator, the drum is rotatably arranged on the frame, and the manipulator is provided with The output end connected by the screw, preferably, the frame is driven to rotate by a driving mechanism, and there are multiple grinding devices, which are arranged on the frame at intervals in the circumferential direction. When the cover is opened each time, the The output end of the manipulator is selectively detachably connected with one of the screw rods. Of course, in order to realize the unlocking, the manipulator is also provided with a part that is movably matched with the drive part, which can press the drive part down, or release the drive part, so that the pawl is disengaged from the ratchet unlocking screw, or the pawl can be r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com