Cotton carding device for HY cellucotton

A fiber cotton and carding technology, applied in the field of HY fiber cotton carding device, can solve the problems of fiber cotton flying, inability to automatically disperse auxiliary materials, accumulation of old cotton on the surface of the licker-in roller, etc., to avoid the effect of blocking cotton.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

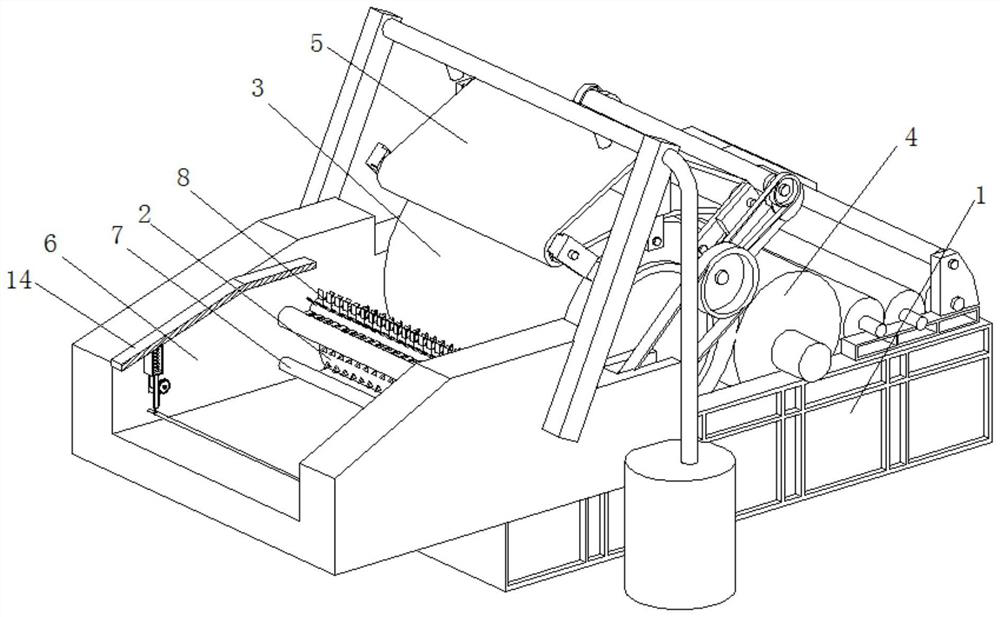

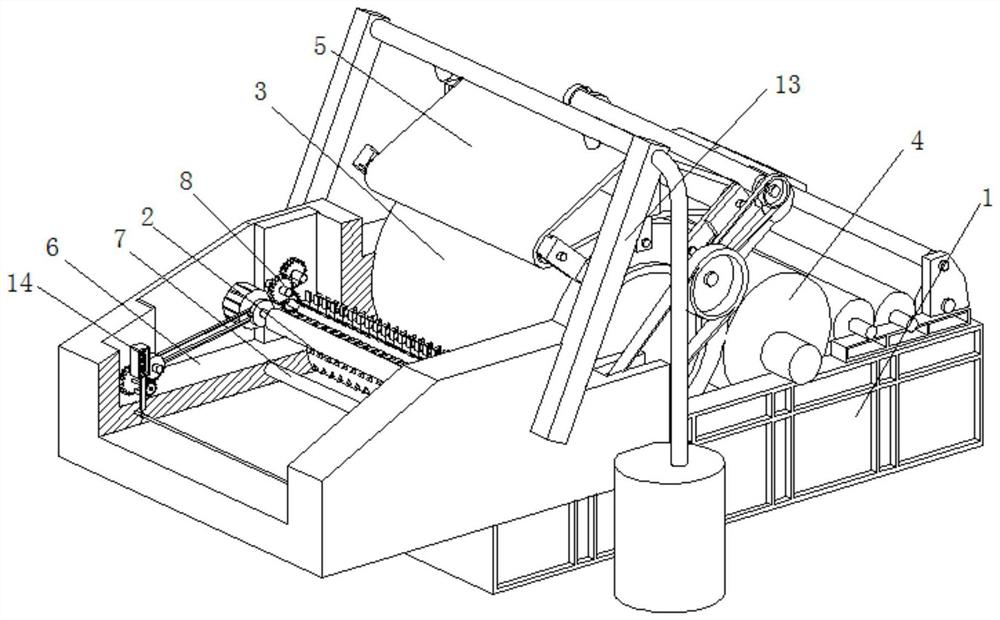

[0033] A kind of carding device of HY fiber cotton, as Figure 1-Figure 6 As shown, it includes body 1, the inside of body 1 is rotatably connected with licker-in roller 2, body 1 is located at the right side of licker-in roller 2 and is rotatably connected with cylinder 3, body 1 is rotatably connected with doffer 4 at the right side of cylinder 3, body 1 The top of the machine body 1 is connected with the cover plate group 5 by bolts, the front part of the machine body 1 is connected with the feeding platform 6 by bolts, the surface of the feeding platform 6 is connected with the pressure roller 7 in rotation, and the inside of the feeding platform 6 is provided with auxiliary carding Mechanism 8, the surface of feeding platform 6 is welded with baffle plate 14.

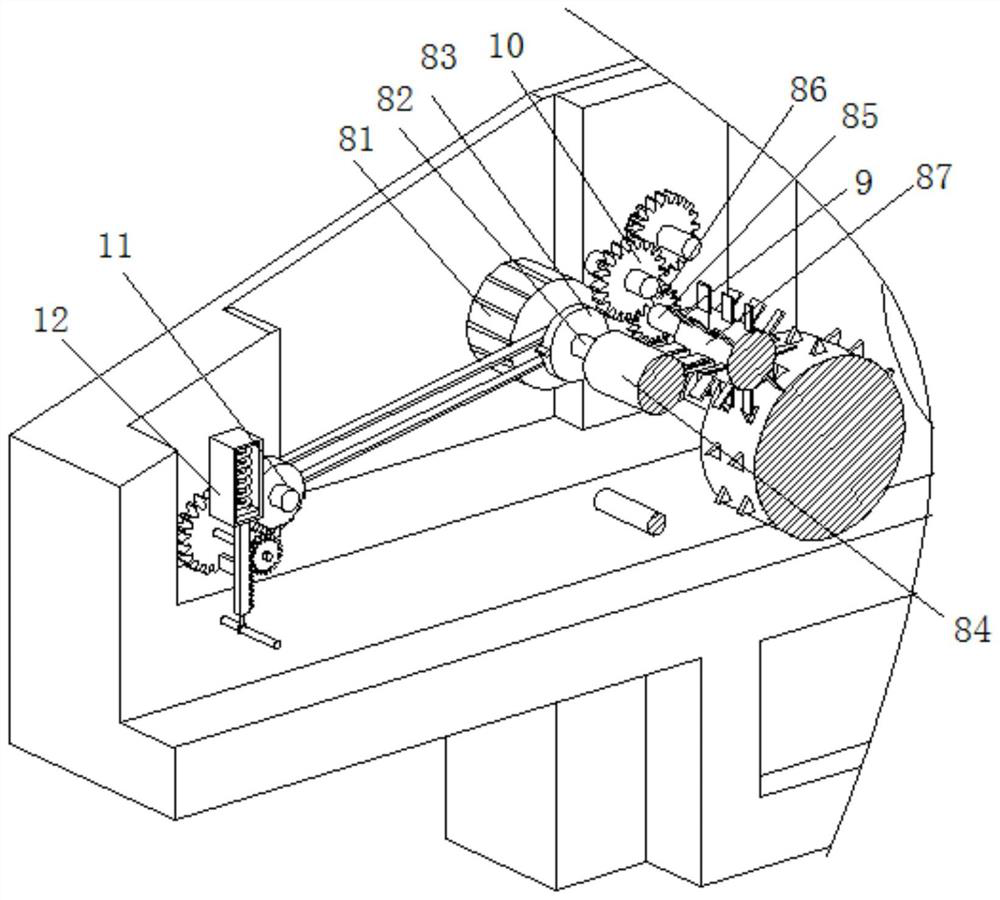

[0034] In this embodiment, the auxiliary carding mechanism 8 includes a motor 81, a rotating roller 85, a connecting device 11 and an absorbing device 13. The surface of the motor 81 is fixedly connected with the i...

Embodiment 2

[0042] Such as Figure 7-Figure 8 As shown, on the basis of Embodiment 1, in this embodiment, the connecting device 11 includes an auxiliary driving roller 111, and both ends of the auxiliary driving roller 111 are rotatably connected with the inner wall of the feeding table 6, and the surface of the auxiliary driving roller 111 Welded with a half toothed disc 112, the surface of the half toothed disc 112 is meshed with a meshing gear 113, the inside of the meshing gear 113 is welded with a connecting shaft 114, and the front end of the connecting shaft 114 is welded with an adjusting gear 115, and the surface of the connecting shaft 114 is connected to the feed table 6 internal swivel connections.

[0043] By setting the connecting device 11, one motor 81 can control the operation of multiple structures, so as to achieve the effect of improving the working efficiency and multi-functional use of the motor 81. By setting the half toothed plate 112, the half toothed plate 112 ca...

Embodiment 3

[0048] Such as Figure 9 As shown, on the basis of Embodiment 1, in this embodiment, the absorption device 13 includes a connecting arm 131, the surface of the connecting arm 131 and the surface of the feeding table 6 are fixedly connected by bolts, and the connecting arm 131 is located above the body 1 Connected with a suction pipe 132, the surface of the suction pipe 132 is welded with a suction nozzle 133, the bottom of the suction pipe 132 is connected with a bellows 134, the inside of the bellows 134 is provided with a storage chamber, the bellows 134 generates suction and the scattered fiber cotton is discharged from the suction nozzle 133 through the suction pipe 132 Internal absorption, thereby achieving the effect of preventing the scattered fiber cotton from being entangled in the body 1 or inhaled by the operator, and further achieving the effect of cleaning.

[0049] The working principle is that the output shaft of the motor 81 drives the driving roller 82 to rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com