Numerically-controlled machine tool housing

A technology for CNC machine tools and housings, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., and can solve the problems of occupying the surrounding space of CNC machine tools, failing to provide a structure for cleaning waste, and inconvenient placement of facilities. , to achieve the effect of increasing the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

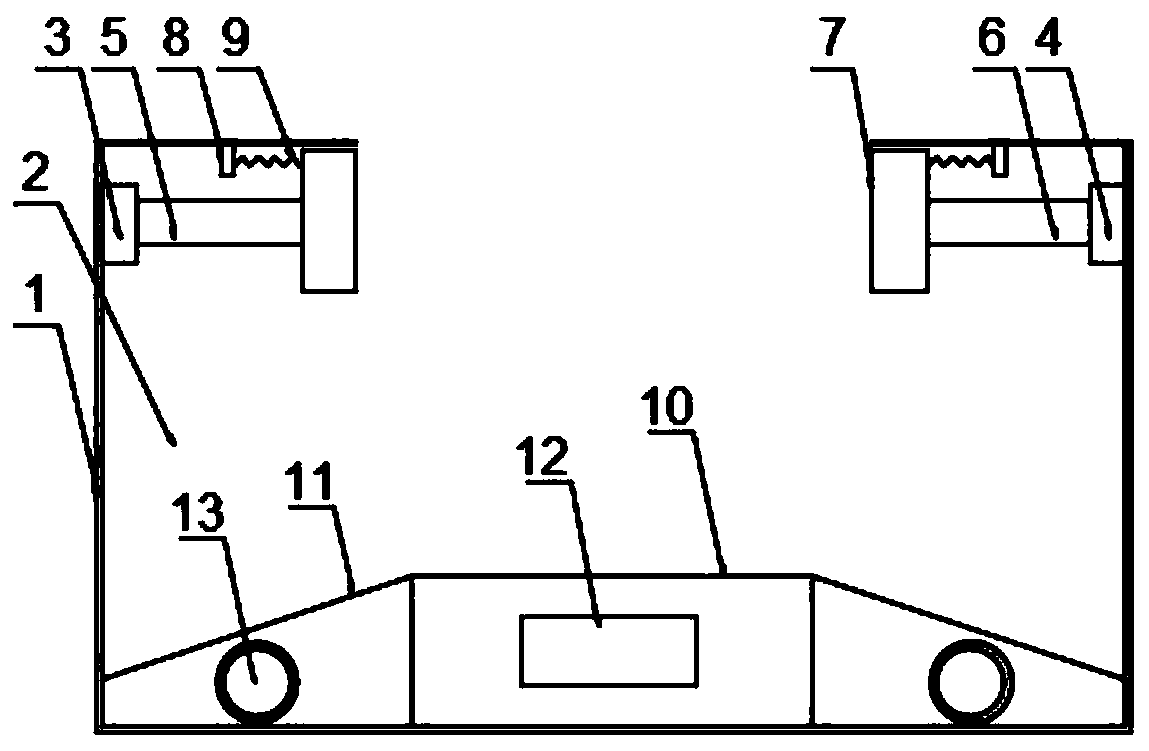

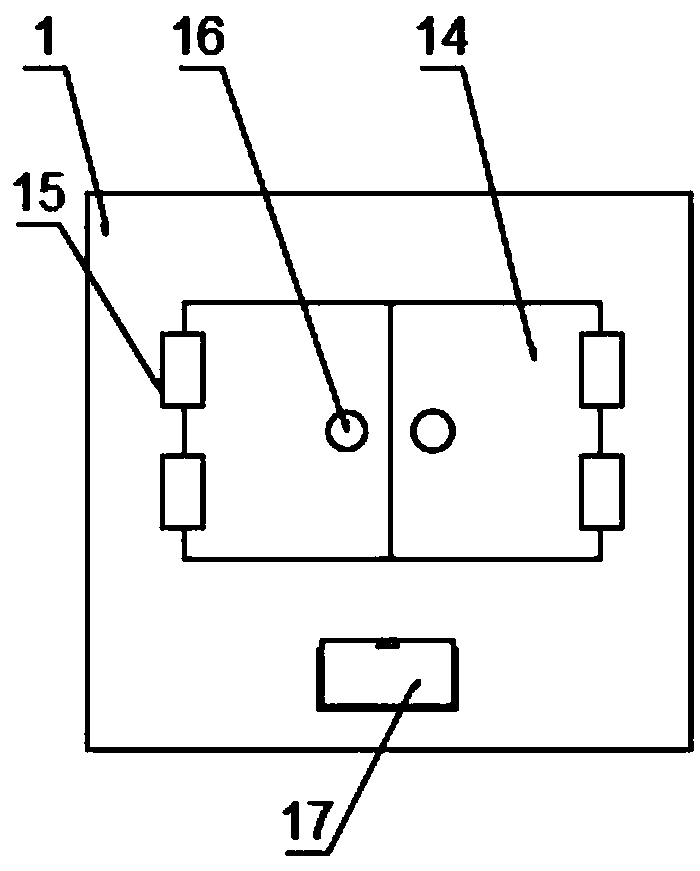

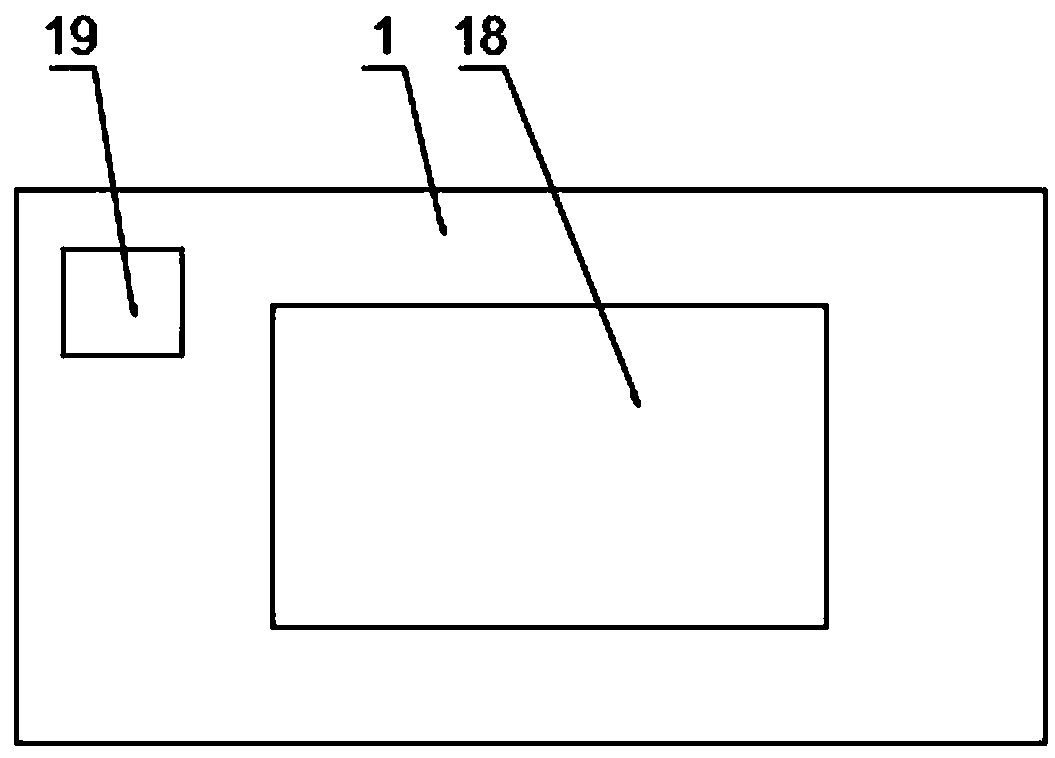

[0019] Such as Figure 1-3 As shown, the present invention provides a CNC machine tool cover, including a cover body 1, a cavity 2, a first base 3, a second base 4, a first telescopic rod 5, a second telescopic rod 6, a clamp 7, and a connecting rod 8. Protective cover 9, workbench 10, inclined plate 11, battery 12, solenoid 13, opening door 14, hinge 15, handle 16, waste collection door 17, observation window 18 and controller 19, cover body 1 The inside is provided with a cavity 2, and the inner side walls of the cavity 2 are respectively provided with a first base 3 and a second base 4, and one end of the first base 3 is provided with a first telescopic rod 5, and the second base 3 One end of the first telescopic rod 6 is provided with a second telescopic rod 6, one end of the first telescopic rod 5 and the second telescopic rod 6 are provided with a clamp 7, the bottom end of the cavity 2 is provided with a workbench 10, and both sides of the workbench 10 are provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com