Device for polishing metallographic experimental sample

A technology for samples and experiments, applied in the field of experimental devices, can solve the problems of fast rotation, flying out of samples, and danger of the surrounding environment of students, and achieves the effect of improving efficiency and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

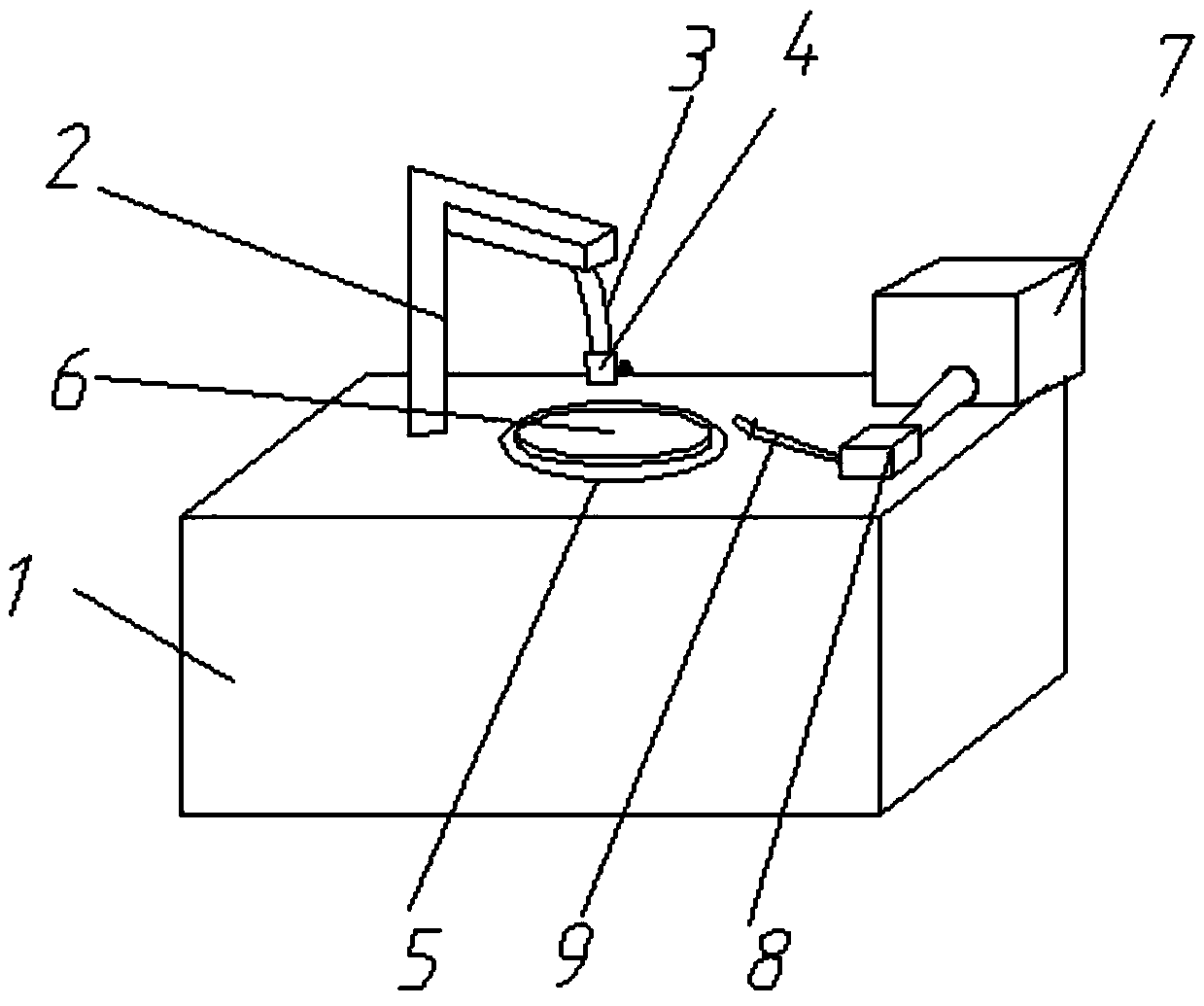

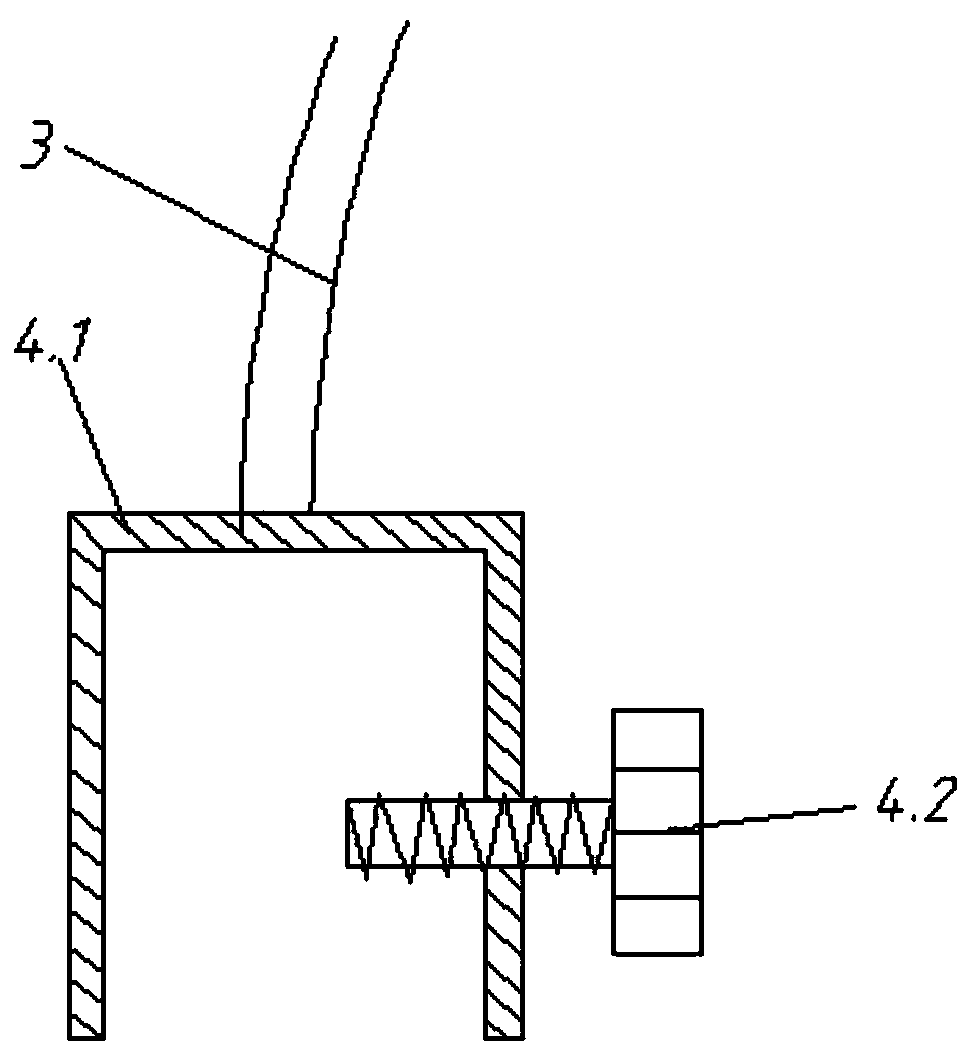

[0017] Such as figure 1 , 2 As shown, a device for grinding metallographic experimental samples includes a base 1, a grinding disc 6, a sample locking mechanism 4, and a water tank 7. A support rod 2 is arranged on the upper surface of the base 1, and the support rod 2 has two sections, which are respectively The vertical section of the vertical state, and the horizontal section of the horizontal state, the top of the vertical section is connected with the leftmost side of the horizontal section, and the elastic hard connecting rod 3 is fixedly connected to the bottom of the rightmost side of the horizontal section. The connecting rod 3 is an elastic material, which can change its shape and maintain its shape when it is not stressed;

[0018] The sample locking mechanism 4 is connected to the bottom of the elastic hard connecting rod 3. On the upper surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com