Rotary engines and cars

A rotary engine and rotor technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as uneven torque output, achieve uniform torque output, optimize temperature environment, and increase air volume and air pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

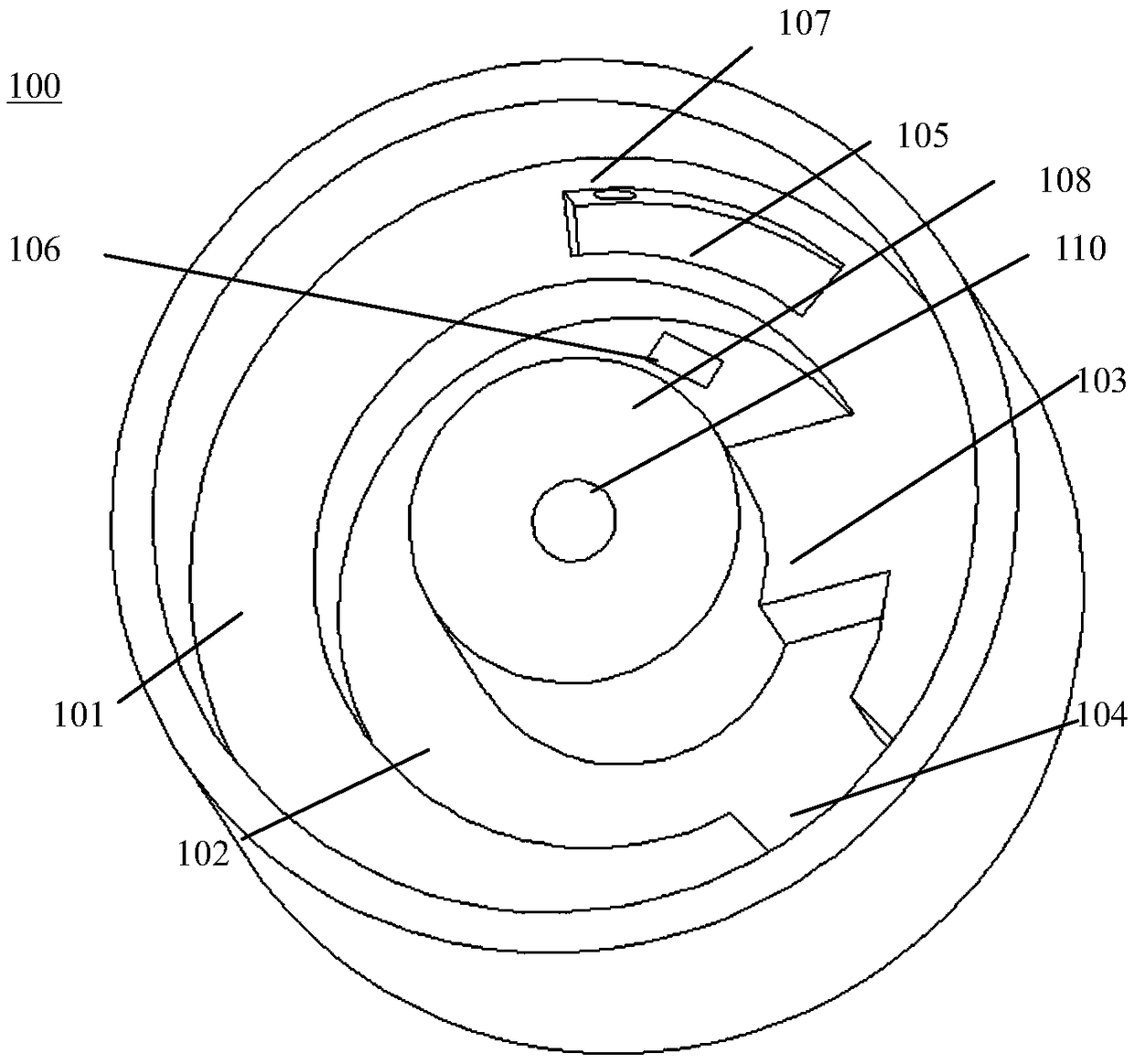

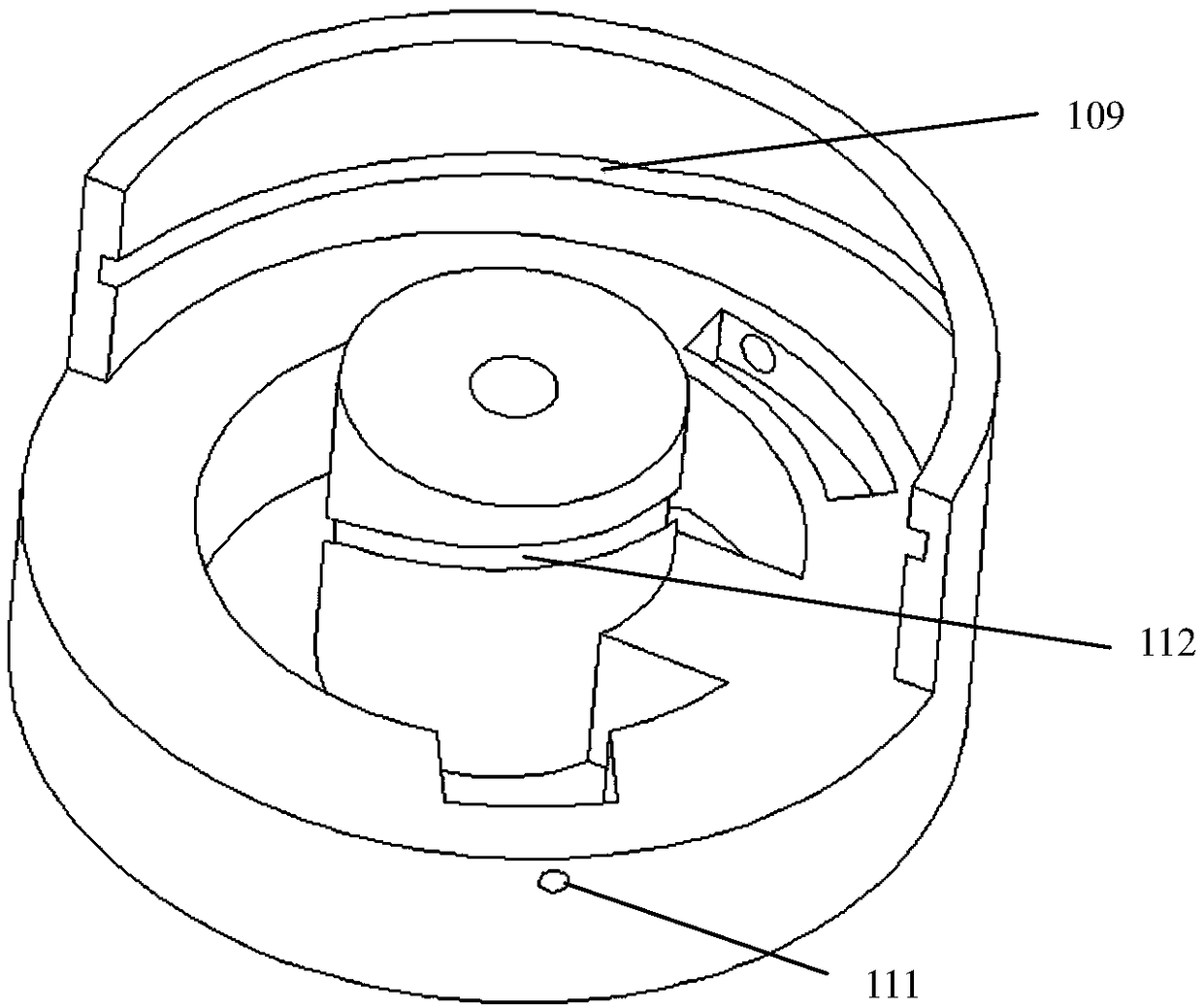

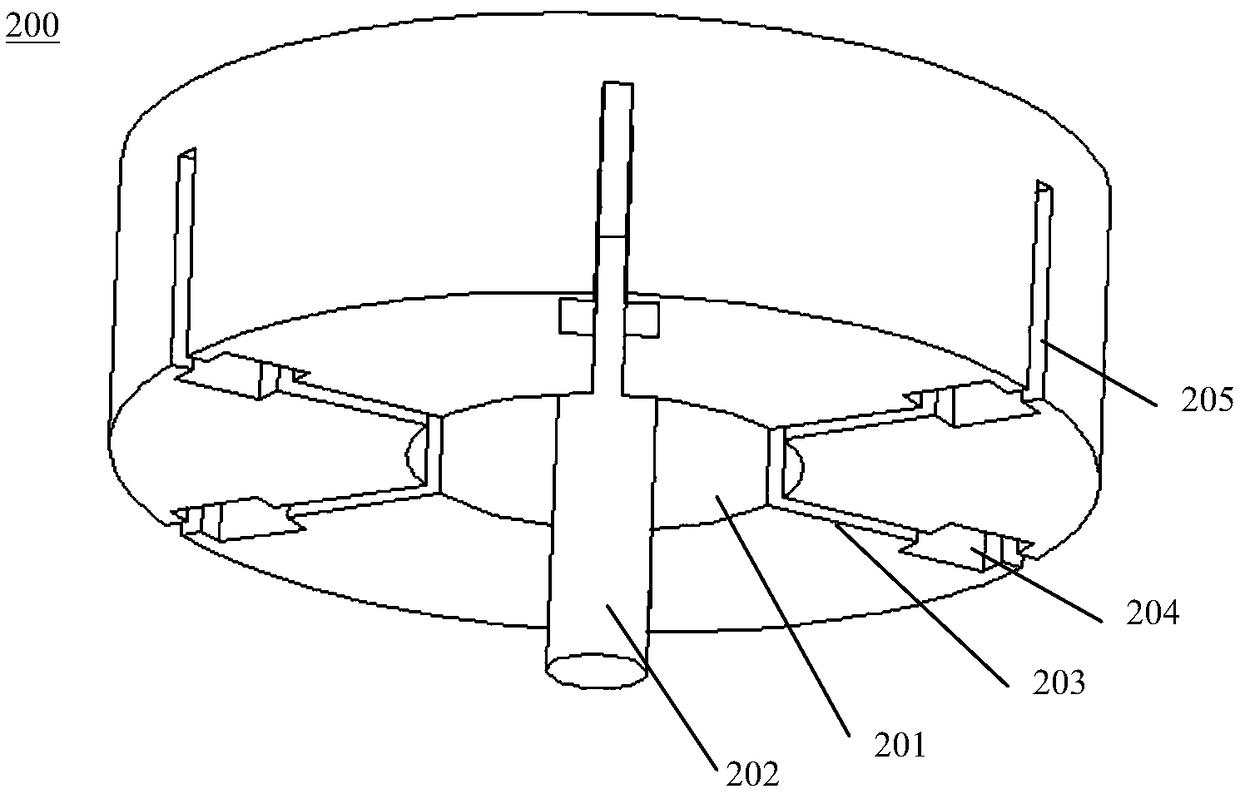

[0055] Such as figure 1 - Figure 8 As shown, a rotary engine is provided in this embodiment, the rotary engine includes a stator 100 and a rotor 200, both of the stator 100 and the rotor 200 are cylindrical, and the rotor 200 is inserted in the stator 100, the rotor 200 is rotationally connected with the stator 100;

[0056] The stator 100 is provided with a stator chamber, and the center of the stator chamber is provided with a rotating shaft seat 108, which is fixedly connected to the inner bottom surface of the stator chamber, and the rotating shaft seat 108 is provided with a power output shaft hole 110; The rotor 200 is correspondingly provided with a shaft hole 201, and the shaft seat 108 is inserted into the shaft hole 201;

[0057] The stator cavity also includes an annular boss 101, the annular boss is a boss with an annular cross section, the annular boss 101 is fixed on the inner side wall of the stator cavity, and the cross section of the annular boss 101 Paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com