Rapid assembly type flow divider

A shunt and assembled technology, applied in the direction of branch pipelines, pipes, pipes/pipe joints/fittings, etc., can solve the problems of high installation cost, unfavorable rapid market demand, time-consuming and labor-intensive construction personnel, etc., to improve the connection strength And rigidity, to prevent the formation of water leakage space, to prevent the effect of running, emitting, dripping and leaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

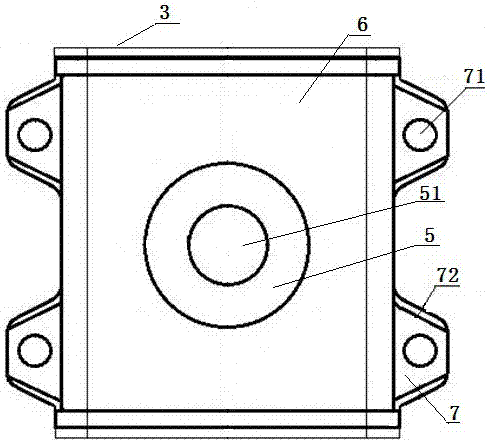

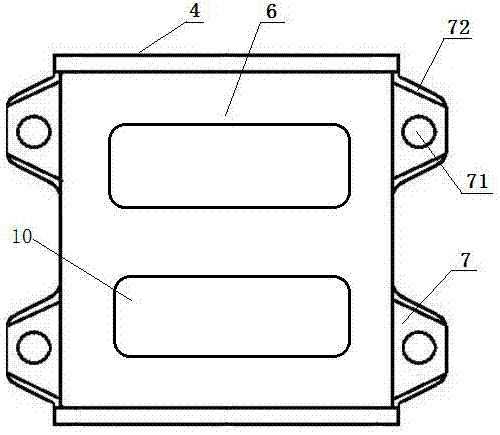

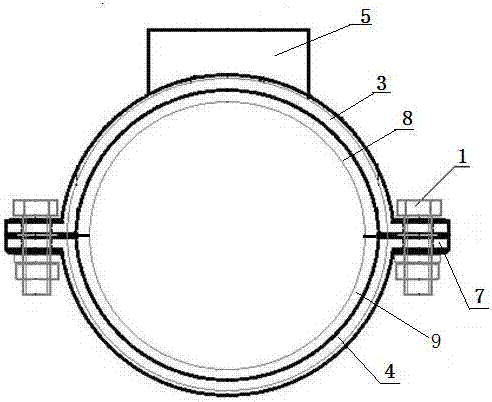

[0032] Such as Figure 1 to Figure 6 As shown, a quick-assembled diverter includes a diversion holding pipe member 3 with a diversion opening 51 with a diversion branch pipe 5 corresponding to the fluid outlet on the main pipeline 2 and connected to the outer wall of the main pipeline 2 through a connector. ; Or also include a fixed holding pipe member 4 without a shunt opening 51 that is snap-fitted and connected with the diverging pipe holding member 3 .

[0033] The present invention includes a diversion holding pipe part 3 and a fixed pipe holding part 4 to form a three-way diverter, and the flow diversion holding pipe part 3 and the fixed pipe holding part 4 are of split type.

[0034] Both the shunt pipe holding part 3 and the fixed pipe holding part 4 include a fitting part 6 which is fastened and in contact with the outer wall of the main pipe 2. On both sides of the fitting part 6, there are several connecting parts 1 to fix the shunt holding pipe part 3 and the fixed...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is that a four-way diverter is composed of two shunt pipe holding parts 3 , that is, no fixed pipe holding part 4 is provided. On both sides of the bonding part 6 of the diversion holding pipe 3, there are several connecting ears 7 that fix the two diversion holding pipes 3 on the main pipeline 2 through the connecting piece 1. The two diversion holding pipes 3 are of split type. Parts such as fastening bolts are fixed. When in use, two holes are poked on the outer wall of the main pipe 2 to correspond to the two diversion holding pipe parts 3. It is suitable for four-way diversion occasions.

Embodiment 3

[0044] The difference between this embodiment and Embodiment 1 is that: a plurality of diversion openings 51 are arranged on the diversion holding pipe member 3 to form a multi-way diverter, and the multi-way diverter includes one or more shunt holding pipe members 3, or also includes one or more fixed The holding pipe piece 4, the shunt holding pipe piece 3 and the fixed holding pipe piece 4 are connected in pieces correspondingly, and are suitable for multi-way shunting occasions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com