Three-dimensional roughness measurement method of object surface based on zoom technology

A technology of object surface and measurement method, applied in measurement devices, instruments, optical devices, etc., can solve the problems of difficult to measure gradient surfaces with large gradients, limited lateral resolution of self-zoom microscopes, etc., to overcome the material and reflection of objects. The influence of rate, overcome locality and one-sidedness, and improve the effect of z-direction positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

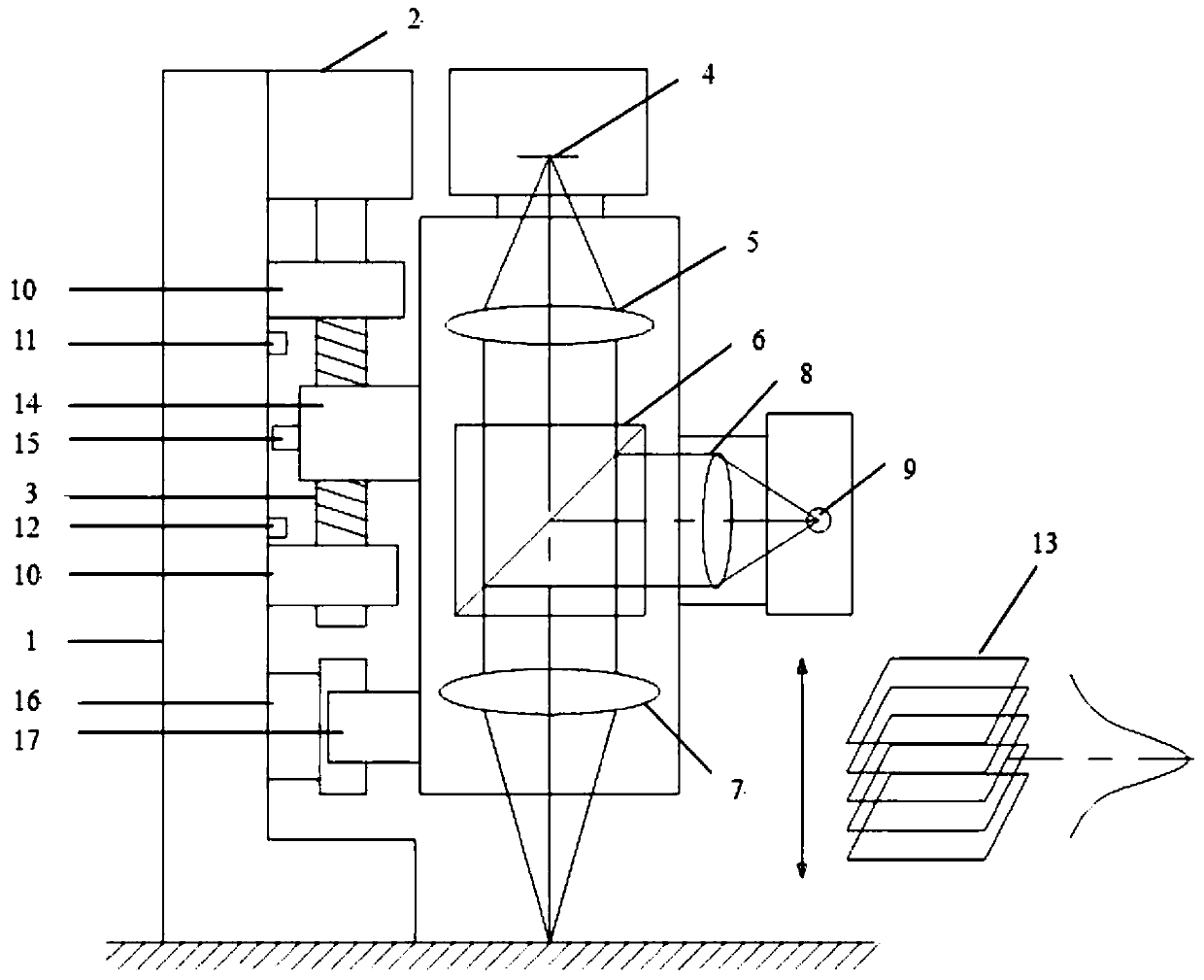

[0034] In this embodiment, a three-dimensional roughness measurement system based on zoom technology, such as figure 1 As shown, it includes: "L" type z-direction support frame 1, stepper motor 2, ball screw 3, optical probe, a pair of screw nut seats 10, upper limit switch 11, lower limit switch 12, ball nut coupling block 14. Limit switch baffle 15, scale grating 16, grating reading head 17;

[0035]A stepper motor 2 is fixed on the upper left inside the longitudinal surface of the "L" type z-direction support frame 1. The function of the stepper motor is to drive the optical probe to move up and down. The speed and steering of the stepper motor are controlled by the motion control card. Software can be used to control the stepping motor to drive the optical probe to move up or down, how far to move, and how fast to move, and the stepping motor driver can be subdivided to improve the running accuracy of the motor, realize the micro-displacement of the optical probe, and impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com