Method for operating a pneumatically driven device for handling workpieces and device for handling workpieces

A pneumatic drive and equipment technology, applied in the direction of mechanical equipment, electrical components, manufacturing tools, etc., can solve problems such as assembly costs that are prone to failure, complex communication devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

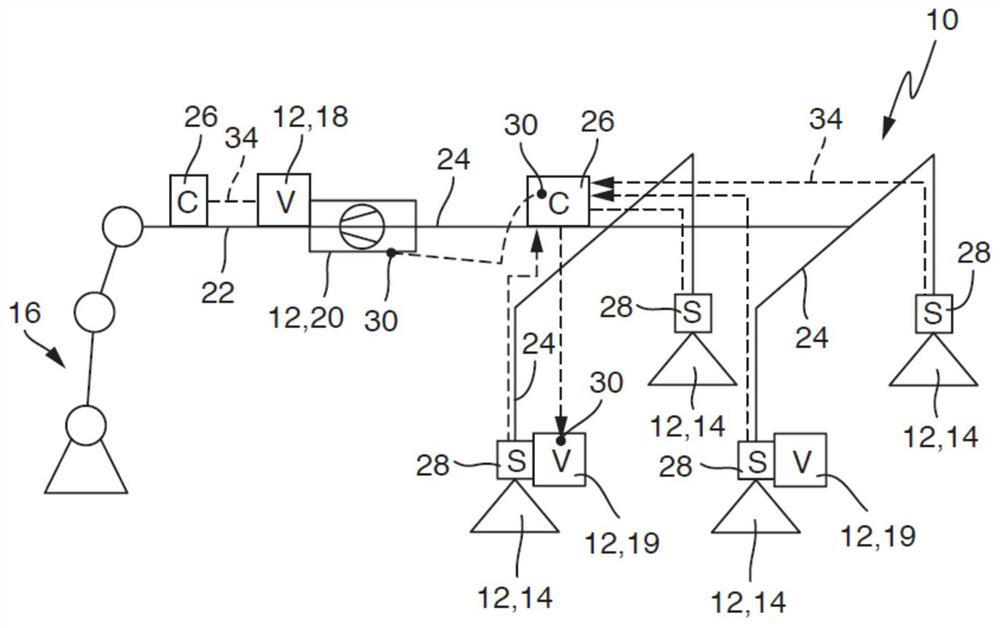

[0030] The method according to the invention and the device according to the invention are exemplarily referred to figure 1 A device 10 for manipulating workpieces is illustrated schematically in FIG. The device 10 is designed as a pneumatic device and includes a set of pneumatic units 12 .

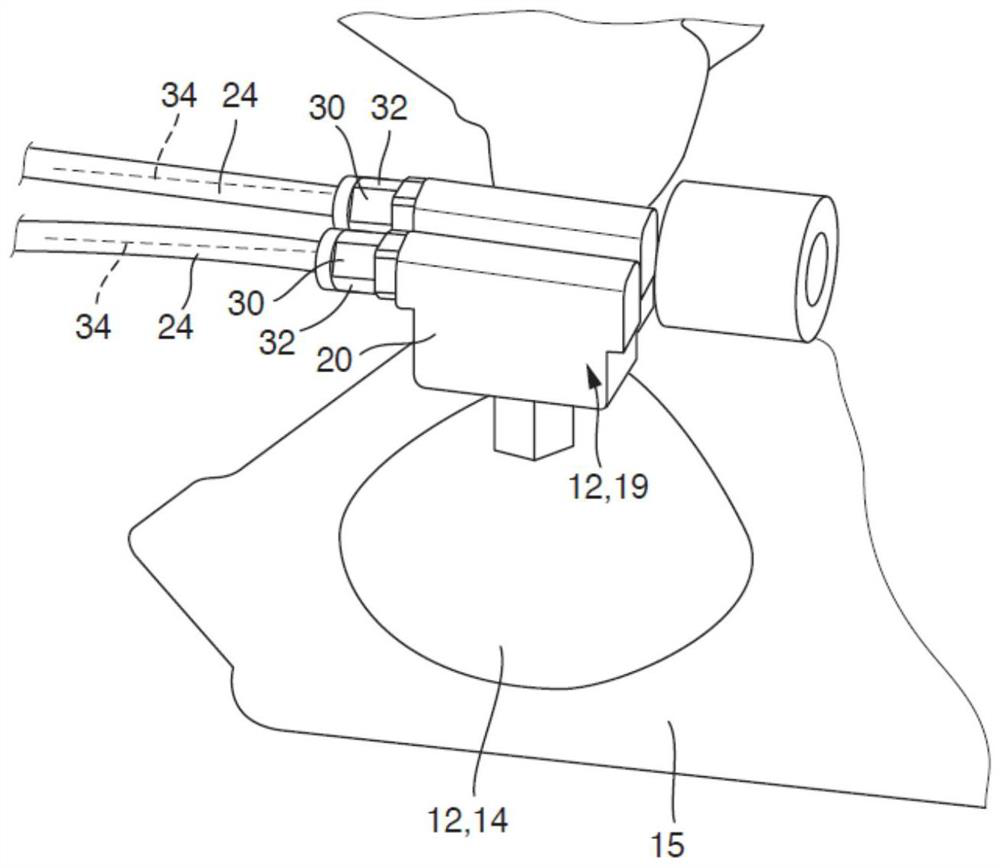

[0031] In the example shown, the pneumatic unit 12 comprises a plurality of suction grab devices 14 constituting the operating actuators 14 of the device 10 . The suction grab device 14 can be arranged on a suitable base frame (not shown in detail). Workpieces that extend spatially can also be secured with this overall arrangement. In order to move the actuator 14 spatially, an actuator 16 can be provided, for example in the form of a robot arm (in figure 1 shown only schematically).

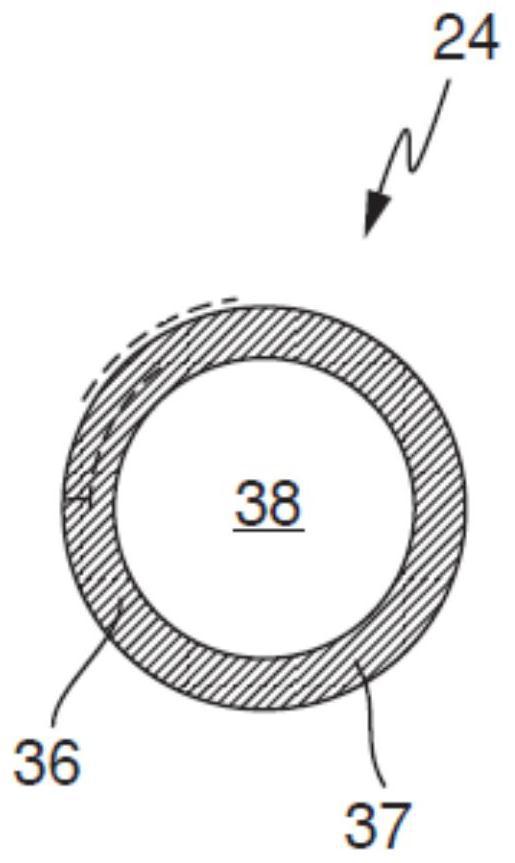

[0032] Furthermore, the device 10 includes further pneumatic units, such as a valve device 18 and a control valve 19 for actuating the actuator 14 . In order to supply the suction grab device 14 with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com