Process and equipment for processing wooden board surface with grid pattern

A surface processing and grid-like technology, which is applied in the field of wood surface processing technology and equipment, can solve the problems of reduced service life and achieve the effects of improving the degree of automation, improving structural performance, improving motion efficiency and accuracy of motion trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

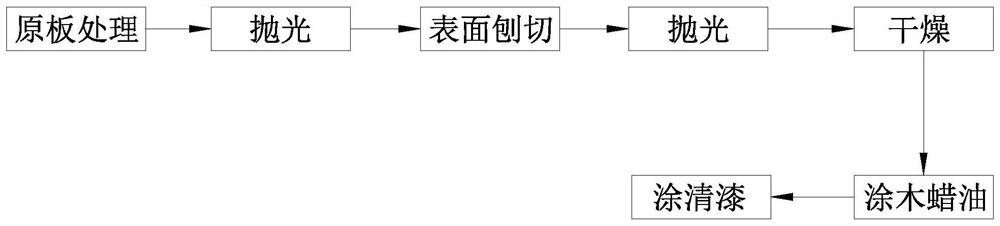

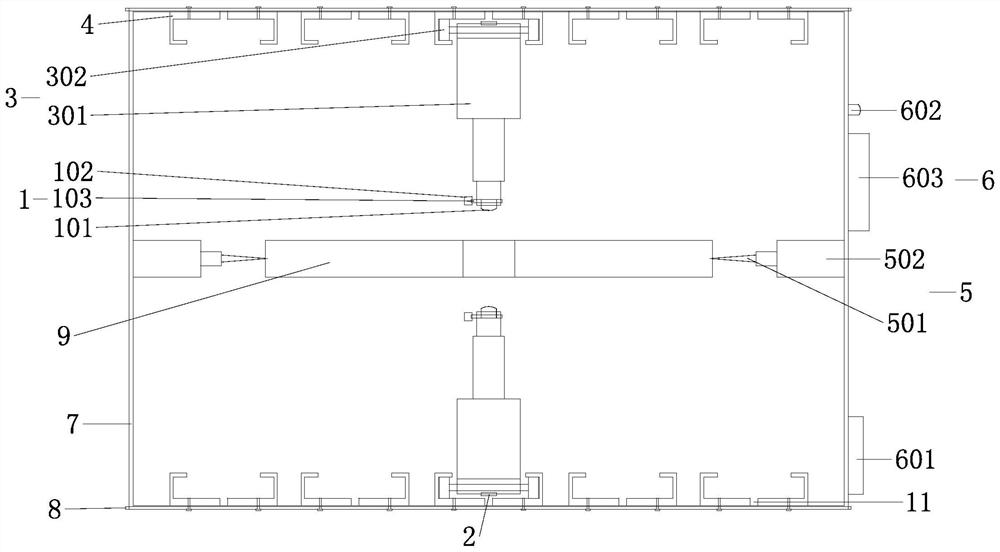

[0040] Such as figure 1 The surface processing process of a grid-like texture refers to the completion of the planing process of the grid-like texture on the surface of the solid wood board to enhance the three-dimensional effect of the surface of the solid wood board used as a decorative panel. The process mainly includes:

[0041] 1) processing of the original board: cutting the edge of the solid wood board 9 so that the cut size meets the processing size requirements;

[0042] 2) Polishing: Select 300-mesh coarse sandpaper to roughly grind the sliced solid wood board along the grain direction of its surface to reduce the roughness of the surface and remove large burrs on the surface;

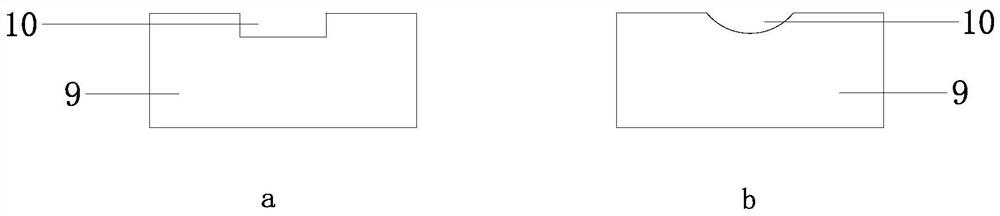

[0043] 3) surface slicing: use plank surface processing equipment to carry out slicing treatment on the surface of the solid wood board 9 after step 2), so that it forms planing marks 10;

[0044] 4) Polishing: Select 900-mesh fine sandpaper to finely polish the surface of the plank 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com