load cell

A technology of load cells and sensitive components, applied in the field of load cells, can solve the problems of sensor performance and life reduction, easy aging, corrosion, high impact, etc., and achieve the effects of easy miniaturization, impact resistance, and guaranteed structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the following, in conjunction with the accompanying drawings, the method provided by the present invention is used in extremely harsh working environments such as high and low temperature, severe impact, vibration, etc., and solves the problem of high-precision force measurement in special environments that require no organic matter and various adhesive structures. The optimal way of the technical solution is further explained:

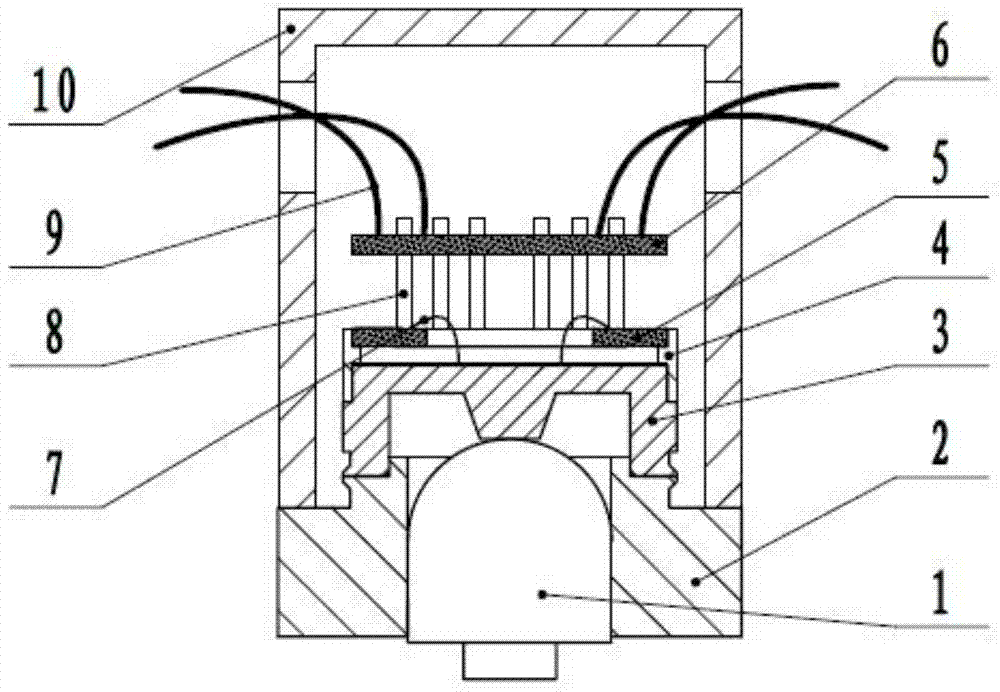

[0017] Its static structure: please refer to the accompanying drawings, the sputtering thin film force sensor of the present invention includes an indenter 1, a base 2, a sensitive element 3, a circuit board seat 4, a lead wire fixing circuit board 5, a multifunctional circuit board 6, a lead wire 7. Pin header (or other conductive column with certain strength) 8, wire 9 and shell 10. Sensitive element 3 is produced and processed by reference to the mature sputtering film pressure sensor sensitive element process. The sensitive element in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com