A camera module and defrosting method

A technology of a camera module and a drive module, which is applied in the field of photography, and can solve problems such as affecting the shooting effect, the camera module does not have a focusing function and a defrosting function, and the protection cover is easy to accumulate frost and fog, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

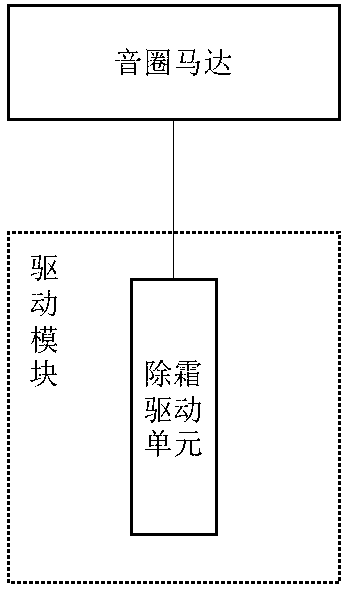

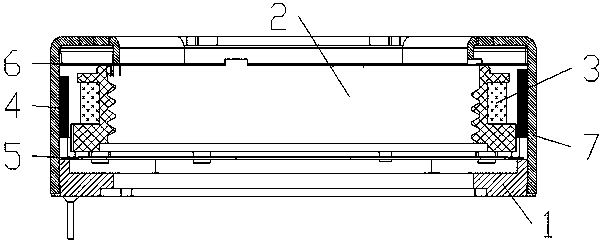

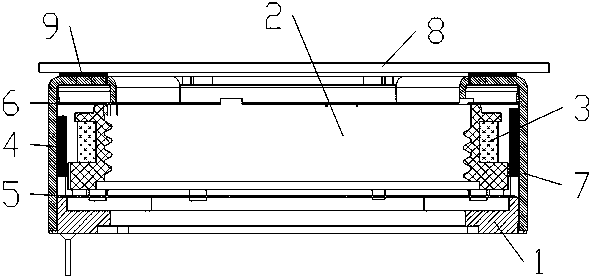

[0028] Such as figure 1 As shown, a camera module includes a driving module, a voice coil motor and a lens, the driving module is electrically connected to the voice coil motor, and the lens is arranged in the voice coil motor. Such as figure 2 As shown, the voice coil motor includes a base 1 and a yoke 7 fitted on the base 1, a magnetic mover and a permanent magnet group 4 are arranged in the accommodation cavity between the base 1 and the yoke 7, The magnetic mover includes a carrier 2 and a focusing coil 3 wound outside the carrier 2, the lower end of the carrier 2 is assembled with the base 1 through the lower elastic piece 5, and the upper end is assembled with the yoke 7 through the upper elastic piece 6 ; The lens is set in the carrier 2 .

[0029] In the existing shooting process, the drive module supplies focus current to the focus coil 3, so that the focus coil 3 generates different dynamic magnetic fields, which interact with the static magnetic field of the perm...

Embodiment 2

[0041] Such as Figure 7 As shown, a defrosting method for a camera module includes the following steps:

[0042] Step 1: Turn on the camera module to shoot;

[0043] Step 2: judging whether there is frost fog on the lens of the camera module;

[0044] Step 3: If there is frost and fog on the lens, the camera module stops shooting, then feeds the first heating current to the focusing coil in the voice coil motor for defrosting, and repeats steps 2 and 3; if there is no frost and fog on the lens , the camera module continues to shoot.

[0045] This defrosting method utilizes the existing focus coil in the voice coil motor of the camera module to heat the lens to achieve the purpose of defrosting, not only does not need to change the existing mechanical structure of the camera module, but also avoids the occurrence The electromagnetic interference caused by the voice coil motor enables the existing camera module to adapt to some harsh and humid natural environments. Since th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com