An anti-suckback adjustable pressure bubbler

A pressure-adjustable, bubbler technology, applied in chemical instruments and methods, chemical/physical processes, feeding devices, etc., can solve problems such as equipment pollution damage, mercury and environmental threats, and inability to prevent back sucking, etc. The effect of preventing the entry of outside air, cleaning is convenient and quick, and the structure is compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

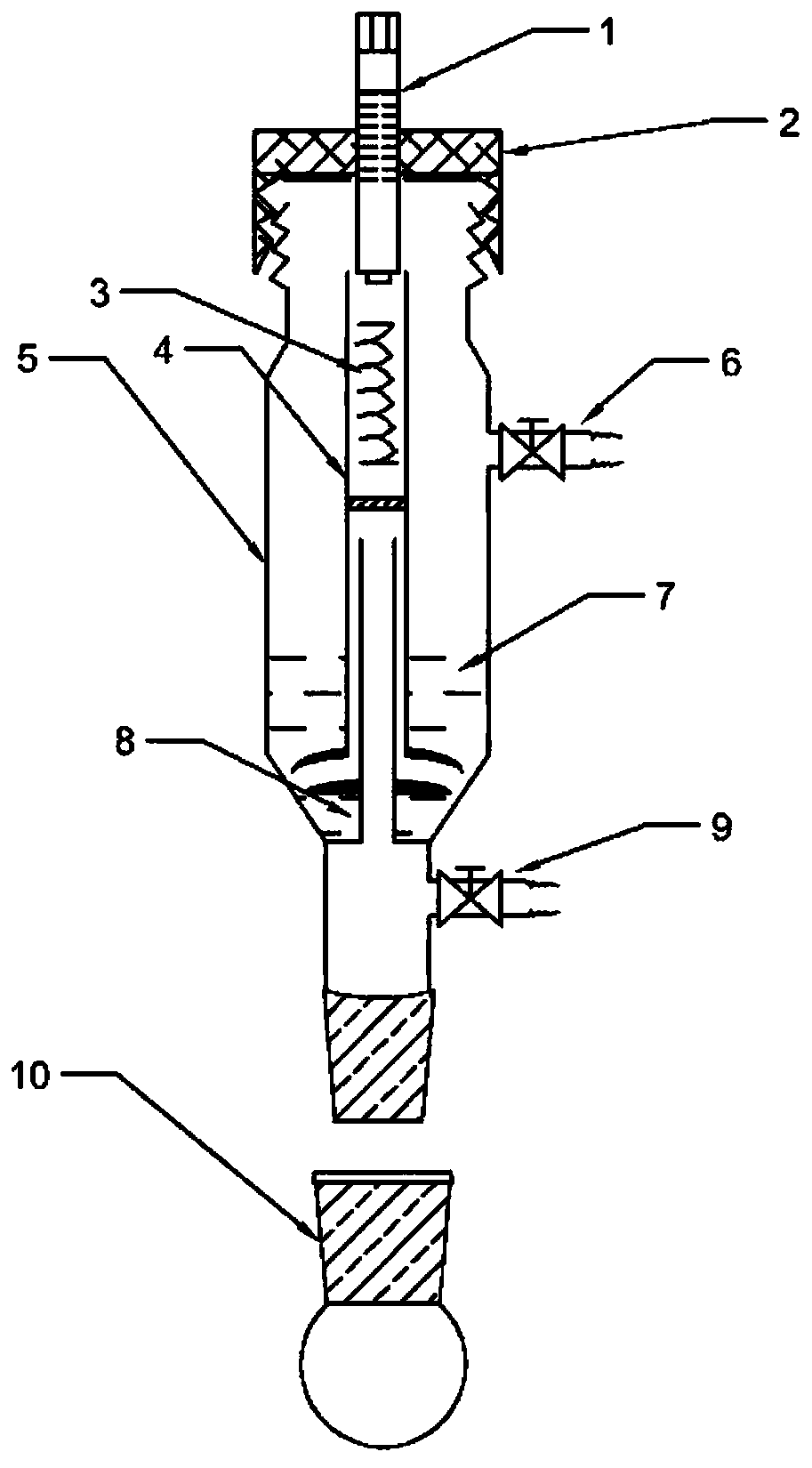

[0028] An anti-suckback adjustable pressure bubbler, its structure is as follows figure 1 As shown, it includes a cylinder 5, an air outlet vertical pipe 8 fixed in the middle of the cylinder 5, a receiving bottle 10 sealed and connected to the bottom of the cylinder 5, a drum pressure sleeve 4 composed of two upper and lower isolated cavities, and the upper cavity Built-in spring 3, the lower cavity is sleeved on the air outlet vertical pipe 8, and the pressure regulating rod 1 abutting against the spring 3, the pressure regulating rod 1 passes through the screw cap 2 arranged on the top of the cylinder body 5.

[0029] Specifically, an air inlet 9 and an air outlet 6 are provided on the side of the cylinder body 5, and the air inlet 9 is located below the air outlet 6, and switch valves are arranged at the air inlet 9 and the air outlet 6 to control them respectively. Gas in and out.

[0030] Both sides of the air outlet standpipe 8 are convex frosted walls, and the convex ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com