Assembly mechanism of grinding module of resistive moisture meter

An assembly mechanism, resistive technology, applied in the field of the assembly mechanism of the rolling module, can solve the problems of unsuitable material diameter, inability to accurately locate, and inaccurate detection, to avoid damage to the rolling wheel and improve detection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

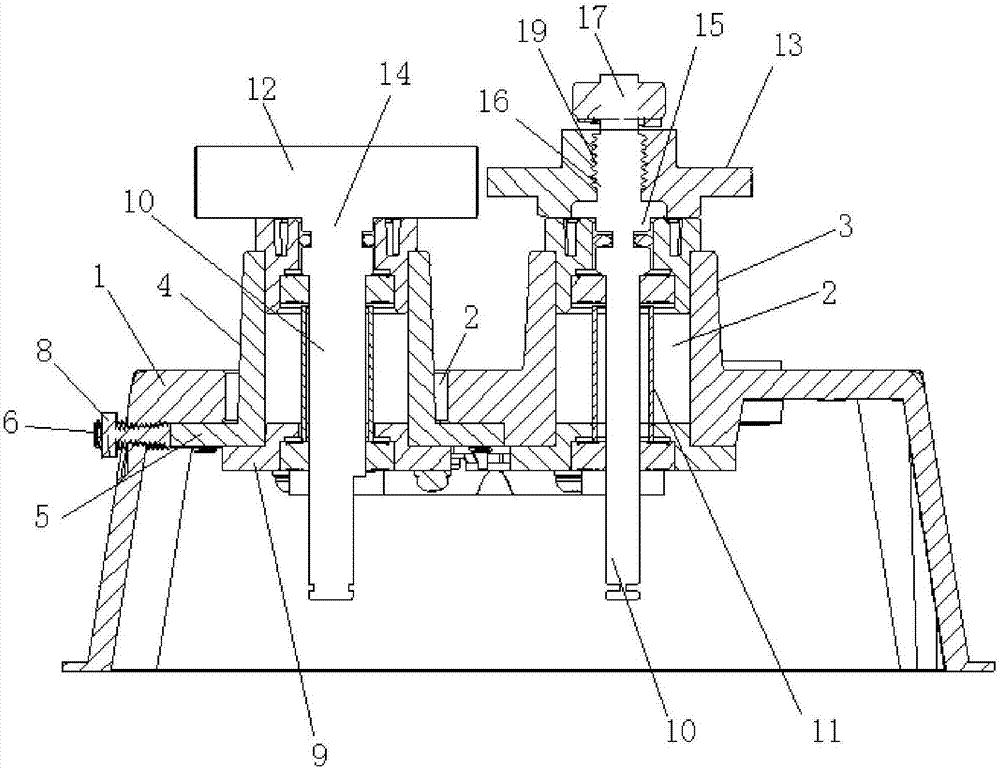

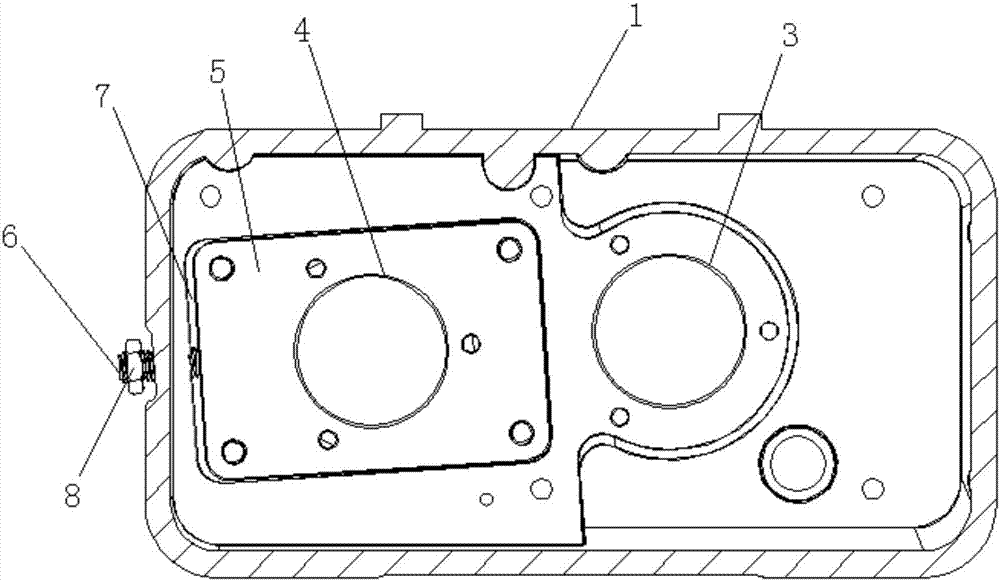

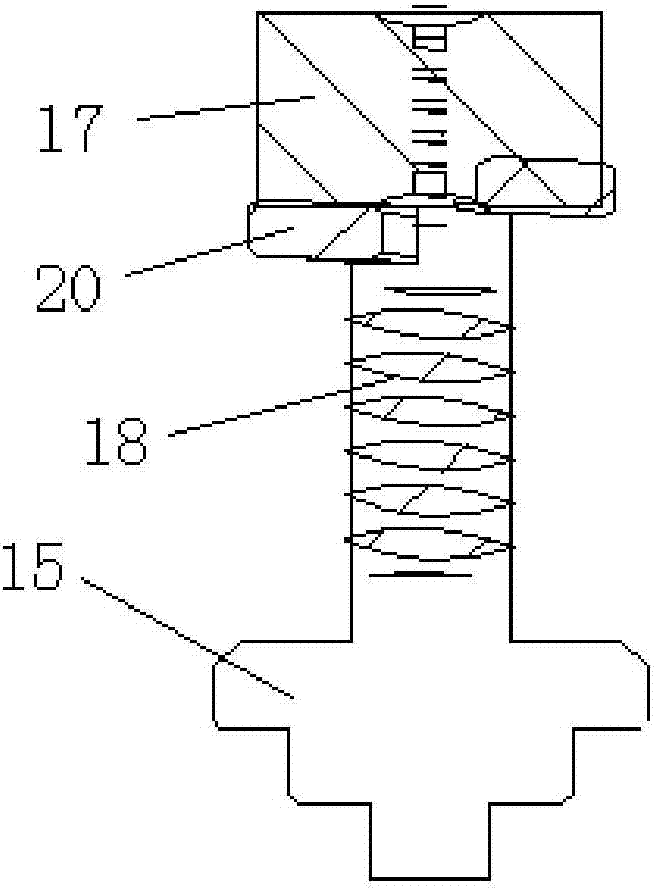

[0014] The present invention will be further described by describing the embodiments below in conjunction with the accompanying drawings.

[0015] like Figure 1~3 As shown, the present invention discloses an assembly mechanism of a rolling module of a resistance moisture meter, which includes a housing 1, and the top of the housing 1 is respectively provided with mounting holes 2 for installing a wide rolling wheel and a narrow rolling wheel , the edge of the hole 2 for installing the narrow rolling wheel is provided with a flanging 3 connected with the housing 1, and a slider 4 is installed in the installation hole for installing the wide rolling wheel, and the bottom of the slider 4 is fixed Push pedal 5 is arranged, and push pedal 5 adopts flat plate, and the bottom of push pedal 5 and slide block 4 is connected as a whole, and push pedal 5 is fixed with the adjusting screw rod 6 that is horizontally arranged on housing 1 side, and the side of housing 1 is provided with fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com