Thermal insulation plate

A technology of thermal insulation board and heat insulation board, which is applied in the direction of paper/cardboard layered products, layered products, metal layered products, etc., can solve the problem that the length of constant temperature time cannot be satisfied, the composite performance cannot be truly realized, and heat insulation The effective range is small and other problems, to achieve good heat insulation effect, reduce heat transfer, long constant temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

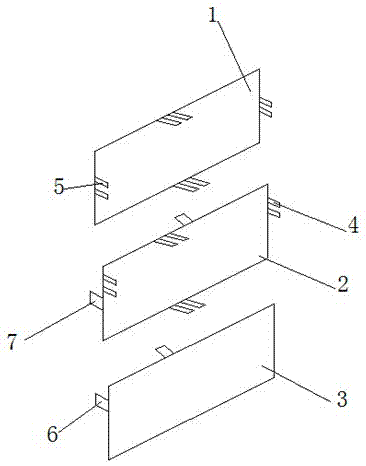

[0019] Such as figure 1 As shown, a thermal insulation board includes an aluminum film layer 1, a foam layer 2 and an isolation layer 3, the aluminum film layer 1 is located in the inner layer of the heat insulation board, the isolation layer 3 is located in the outer layer of the heat insulation board, and the foam layer 2 Located between the aluminum film layer 1 and the isolation layer 3, the outer side of the foam layer 2 is provided with a first U-shaped groove 4, the inner side of the isolation layer 3 is provided with a first extension end 6, and the first extension end 6 is snap-connected to the In the first U-shaped groove 4, a second U-shaped groove 5 is arranged on the outer side of the aluminum film layer 1, and a second protruding end 7 is arranged on the inner side of the foam layer 2, and the second protruding end 7 is connected to the second U-shaped groove. Groove 5 snaps and connects.

[0020] In order to ensure the strength of the engagement, there are four...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap