Steel plate and polyvinyl alcohol cement based composite antiknock board

A polyvinyl alcohol and cement-based technology, applied in the direction of floors, buildings, building components, etc., can solve the problems of building structure damage, building collapse, and lack of anti-blast performance, so as to improve anti-blast performance and large bending deformation capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

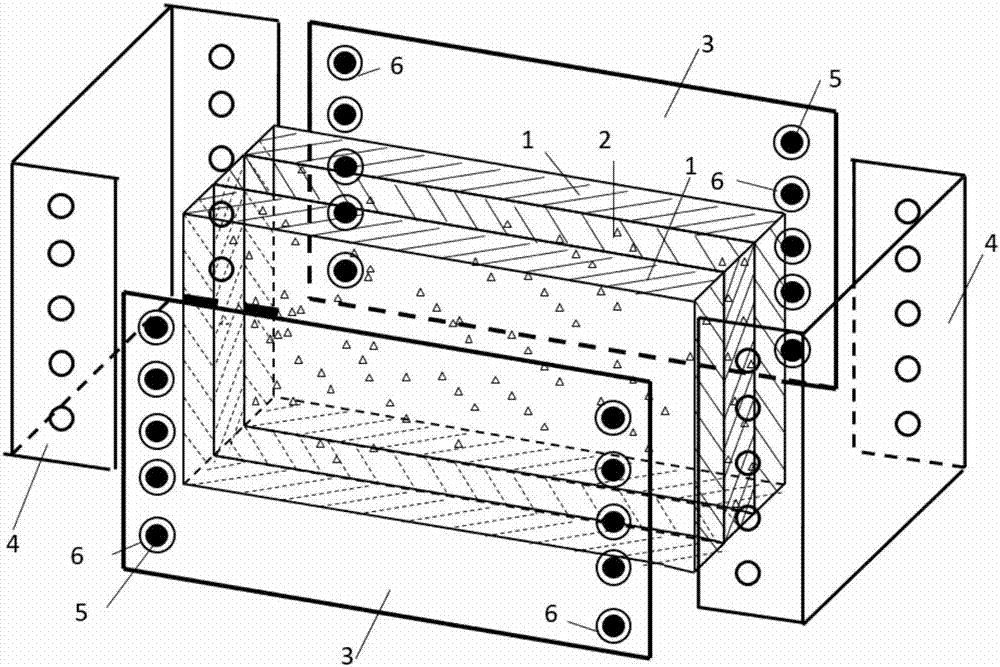

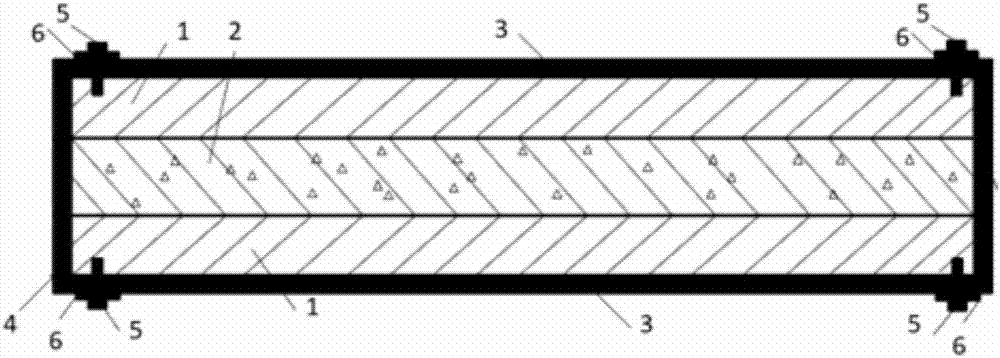

[0017] Such as Figure 1-Figure 2 Shown is a steel plate polyvinyl alcohol cement-based composite anti-explosion plate, including polyvinyl alcohol composite filler 1, foamed aluminum filler 2, support plate 3, U-shaped groove steel plate 4, high-strength bolts 5 and steel pads 6;

[0018] An aluminum foam filler 2 is arranged between the two polyvinyl alcohol composite fillers 1;

[0019] Insert the two support plates 3 into the groove of the U-shaped groove steel plate 4 to form a cavity;

[0020] The polyvinyl alcohol composite filling body 1 sandwiched with the aluminum foam filling body 2 is placed in the cavity;

[0021] The support plate 3 and the U-shaped groove steel plate 4 are provided with symmetrically installed bolt holes;

[0022] The support plate 3 and the U-shaped groove steel plate 4 are connected to the polyvinyl alcohol composite filling body through high-strength bolts 5;

[0023] A steel pad 6 is provided between the U-shaped channel steel plate 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com