Electric wire or cable threading bended protective pipe device

A wire and cable and pipe protection device technology, applied in the direction of cable laying equipment, etc., can solve the problems of increased labor intensity of operators, damage to protective sleeves, and low work efficiency, so as to prevent loose connections, reduce work intensity, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

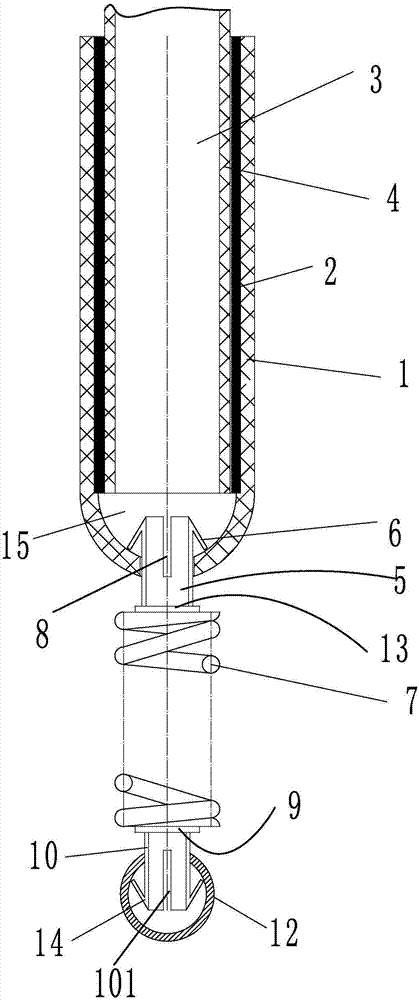

[0034] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a wire and cable bending protection tube device includes a cable holding block 1, the rear end of the cable holding block 1 is provided with an axial hole, and the cable holding block 1 passes through the axial hole and the outer protective layer 4 of the wire and cable To prevent the wire core 3 of the wire and cable from being damaged by external forces such as extrusion, the front end of the cable holding block 1 is connected to the head guide structure.

[0035] A protective layer 2 is provided between the inner surface of the axial hole and the outer protective layer 4 to protect the cables and increase friction.

[0036] The head guide structure includes a spherical or ellipsoidal guide head 12, which is connected to the front end of the cable holding block through an elastic structure with predetermined rigidity. The connection through the elastic structure can increase the bending deform...

Embodiment 2

[0042] like Image 6 As shown, the front end of the connecting body 10 is provided with a sphere 21, and the sphere 21 cooperates with the spherical inner cavity hole 1 of the guide head 12. The front end of the connecting body 8 is connected to the ball 21 through a detachable screw thread.

[0043] The rear end of the position-limiting boss one 9 is connected with the auxiliary connecting block one 23, and the spring connecting block one 22 is fixedly connected at the front end of the spring, and the auxiliary connecting block one 23 and the spring connecting block one 22 are connected by screw threads.

[0044] The front part of the cable holding block 1 is provided with a hemispherical inner cavity 15, and the middle of the rear part of the hemispherical inner cavity 15 is provided with an inner cavity opening, and the rear end of the spring is connected with the second movable connector, and the second movable connector includes Connecting body two 5; the rear end of con...

Embodiment 3

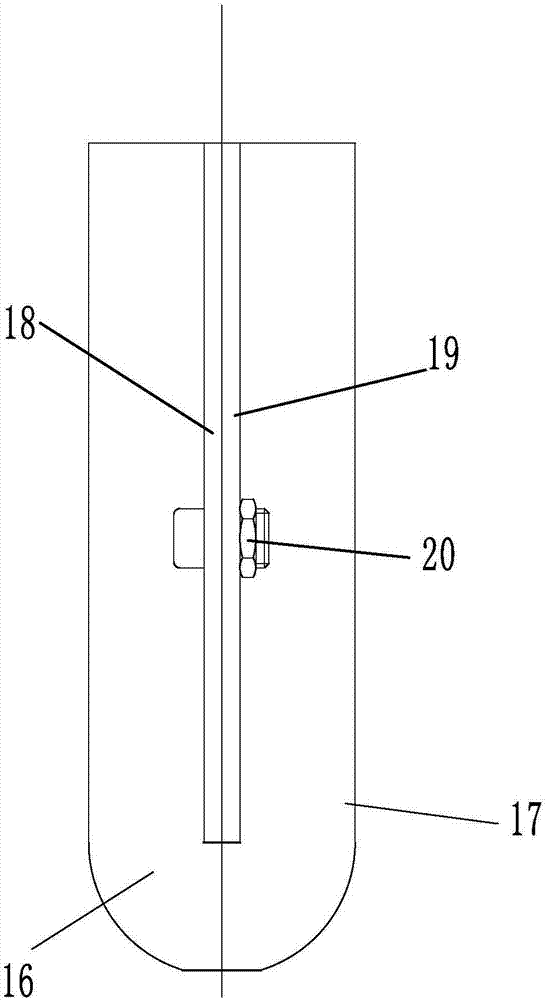

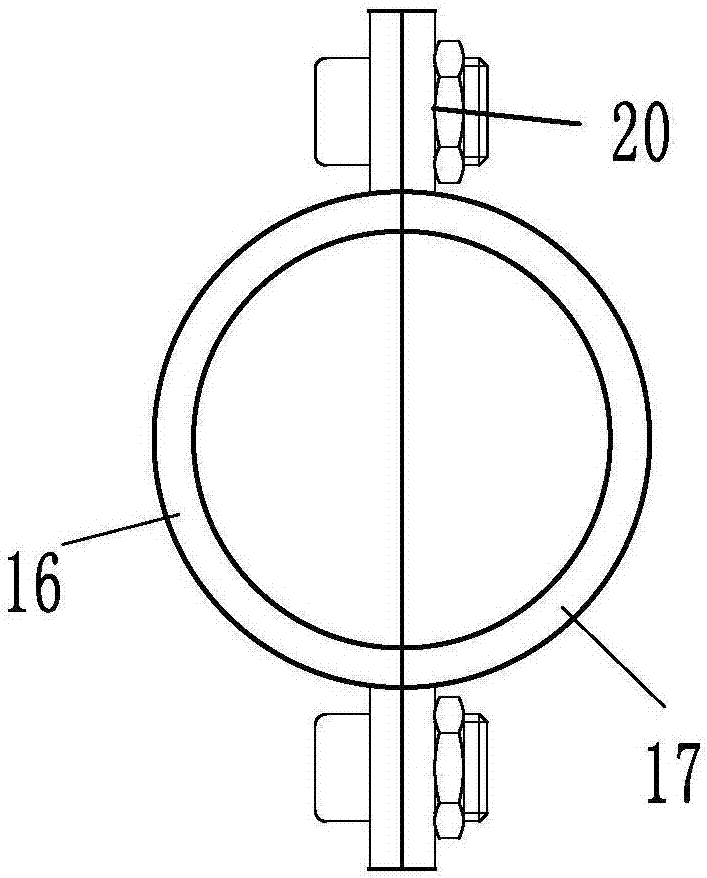

[0047] like Figure 7 As shown, on the basis of embodiment 1 or embodiment 2, a hemispherical body 24 is provided at the rear end of the connecting body two 5, and the hemispherical body 24 cooperates with the hemispherical inner cavity 15, and the hemispherical body 24 and the connecting body two 5 The rear end is connected by threads. Through the cooperation of the hemispherical body 24 and the hemispherical inner cavity 15, the hemispherical body 24 and the hemispherical inner cavity 15 can relatively swing and rotate, which increases the guiding effect of the guide head. The friction resistance of the head becomes smaller, and it can move to the side of the protective sleeve to pass through the bending position smoothly, ensuring that the wires and cables pass through the protective sleeve smoothly. The position of relative movement, or the position of swing and rotation between the hemispherical body 24 and the hemispherical inner cavity 15 can be limited by the limiting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com