Air guide bar rotating shaft system for air conditioner

A technology of air guide strips and air conditioners, applied in space heating and ventilation details, applications, household heating, etc., can solve problems such as potential safety hazards, achieve the effects of preventing rotation and slipping, improving installation efficiency, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific examples.

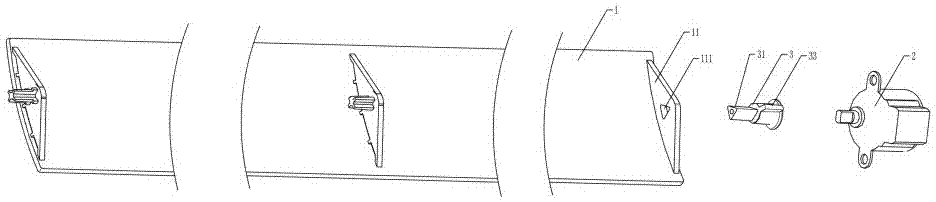

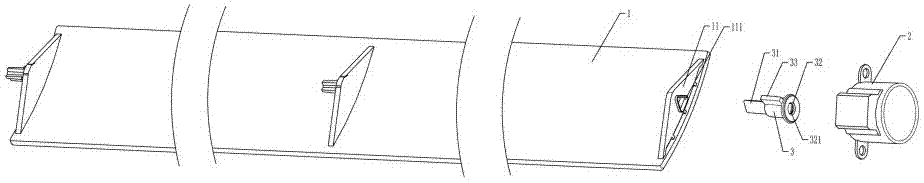

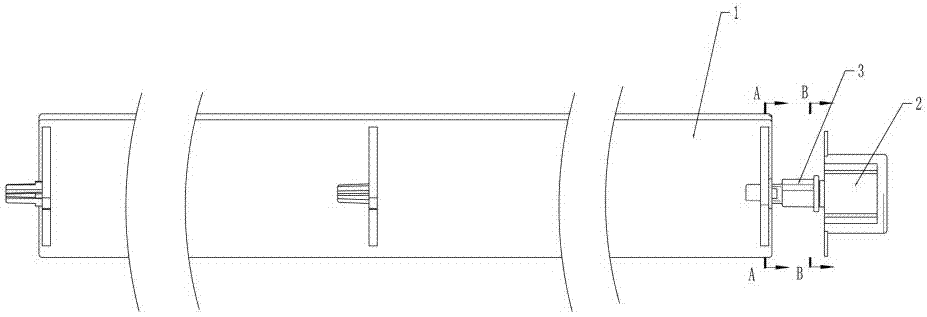

[0015] See attached figure 1 to attach Figure 5 As shown, in this embodiment, an air guide bar shaft system for an air conditioner includes an air guide bar 1, a rotating motor 2 and a shaft sleeve 3, wherein a connecting portion 11 is formed on the air guide bar 1; One end is formed with a conduction portion 31 that matches the conduction slot 111 provided on the connecting portion 11, wherein the conduction portion 31 and the conduction slot 111 are in the shape of an equilateral triangle; due to the effect of the equilateral triangle, the No slipping during the conduction process; the other end of the rotating shaft sleeve 3 is provided with a motor shaft clamping groove 32 that is matched and connected with the rotating shaft of the rotating motor 2, wherein the inner side of the motor shaft clamping groove 32 is formed with a stopper that matches the motor shaft 321, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com