Dielectric ceramic assembly, dielectric ceramic communication electronic component and manufacturing method thereof

A technology of electronic components and dielectric ceramics, which is applied in the direction of waveguide devices, circuits, electrical components, etc., can solve the problems that the silver coating is easily corroded by solder, the silver coating is not resistant to welding heat, and it is unfavorable to withstand welding heat for many times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

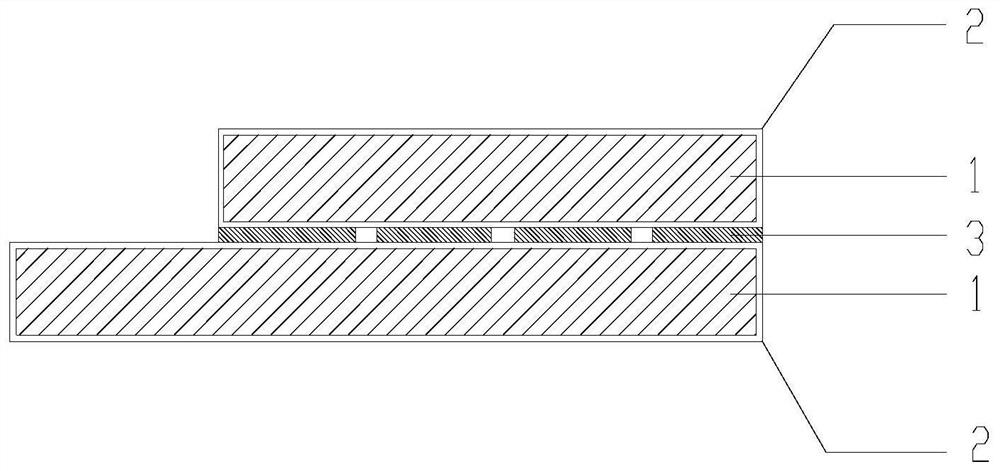

[0047] This embodiment provides a dielectric ceramic component, which is applied to dielectric ceramic communication electronic components. Specifically, refer to figure 1 , the dielectric ceramic assembly includes at least two dielectric ceramic blocks 1; at least two dielectric ceramic blocks 1 are laminated; the outer surface of each dielectric ceramic block 1 is coated with a metal conductive layer 2; two adjacent dielectric ceramic blocks 1 A viscous slurry layer 3 is printed on the opposite surfaces of the metal conductive layers 2 facing each other, the viscous slurry layer 3 includes metal powder, glass phase and organic additives, and the metal conductive layers of two adjacent dielectric ceramic blocks 1 The viscous slurry layers 3 on the layer 2 are attached to each other; the metal conductive layers 2 of two adjacent dielectric ceramic blocks 1 are welded to each other.

[0048] In this embodiment, the metal conductive layers 2 of two adjacent dielectric ceramic bl...

Embodiment 2

[0054] This embodiment provides a dielectric ceramic communication electronic component, and the dielectric ceramic communication electronic component includes the dielectric ceramic component provided in any optional implementation manner in the first embodiment.

[0055] Since the dielectric ceramic communication electronic components provided in this embodiment include the dielectric ceramic components described in Embodiment 1, the dielectric ceramic communication electronic components provided in this embodiment can achieve all the benefits that the dielectric ceramic components in Embodiment 1 can achieve. The effect, its specific structure and achievable effect can be obtained with reference to each optional or preferred implementation in Example 1.

Embodiment 3

[0057] An embodiment of the present invention provides a method for manufacturing a dielectric ceramic communication electronic component, which is used for manufacturing the dielectric ceramic communication electronic component provided in the second aspect. The method for manufacturing a dielectric ceramic communication electronic component includes manufacturing a dielectric ceramic component.

[0058] Specifically, making the dielectric ceramic assembly includes: printing a viscous paste on the metal conductive layer 2 of the dielectric ceramic block 1 covered with a metal conductive layer 2 on the outer surface to form a viscous paste layer 3. The specific printing method includes but is not limited to silk Screen printing; drying the dielectric ceramic block 1 printed with the viscous slurry layer 3 at a temperature of 120°C-250°C; drying the medium ceramic block 1 at a temperature of 120°C-250°C The ceramic block 1 is deglued at a temperature of 450°C to 650°C; the visco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com