Material sampling device for product quality detection and using method thereof

A technology of product quality and sampling device, applied in the direction of sampling device, etc., can solve the problems of difficult detection, waste of products, excessive sampling, etc., and achieve the effect of improving sampling accuracy, avoiding excessive extraction, and avoiding insufficient extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

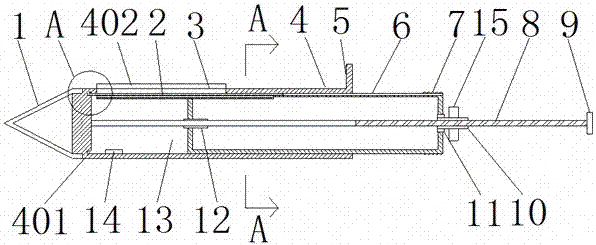

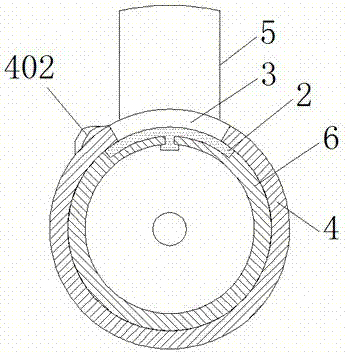

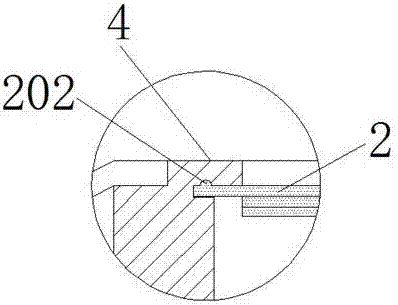

[0029] The present invention provides such as Figure 1-5 The shown material sampling device for product quality detection includes an outer sleeve 4 and an inner sleeve 6. The closed end of the outer sleeve 4 is threadedly connected to the bottom of the cone head 1, which is convenient for the removal of the cone head 1 and is beneficial to Cleaning and maintenance after use.

[0030] The other end of the outer sleeve 4 is fixedly connected with a handle 5, the outer sleeve 4 is provided with a sampling window 3 along the direction of the generatrix, the inner closed end of the outer sleeve 4 is fixedly connected to one end of the connecting rod 8, and the The connecting rod 8 is arranged along the inner centerline of the outer sleeve 4 and the inner sleeve 6, and passes through the inner sleeve 6. The other end of the connecting rod 8 is fixedly connected with a top block 9, and the top block 9 is used to restrict The stroke of the inner sleeve 6 prevents the inner threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com