A method for characterizing the pore structure of shale gas reservoirs and an evaluation method for shale gas reservoirs

A pore structure and shale gas technology, applied in the field of natural gas exploration, can solve the problems of different measurement ranges, inability to objectively characterize the pore structure characteristics, and impossible to fully characterize the micro-nano pore structure characteristics of shale reservoirs. The effect of characterizing results accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

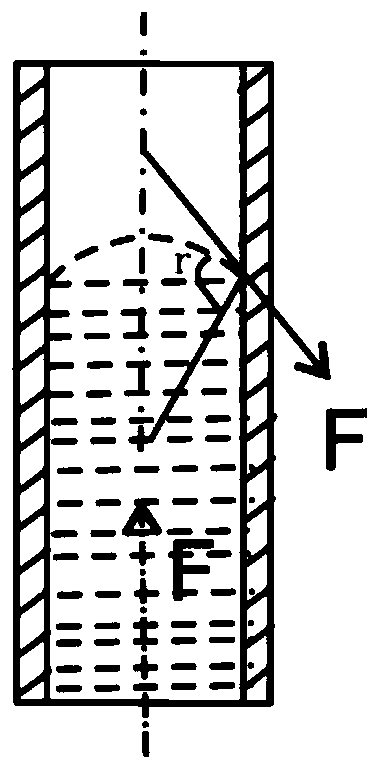

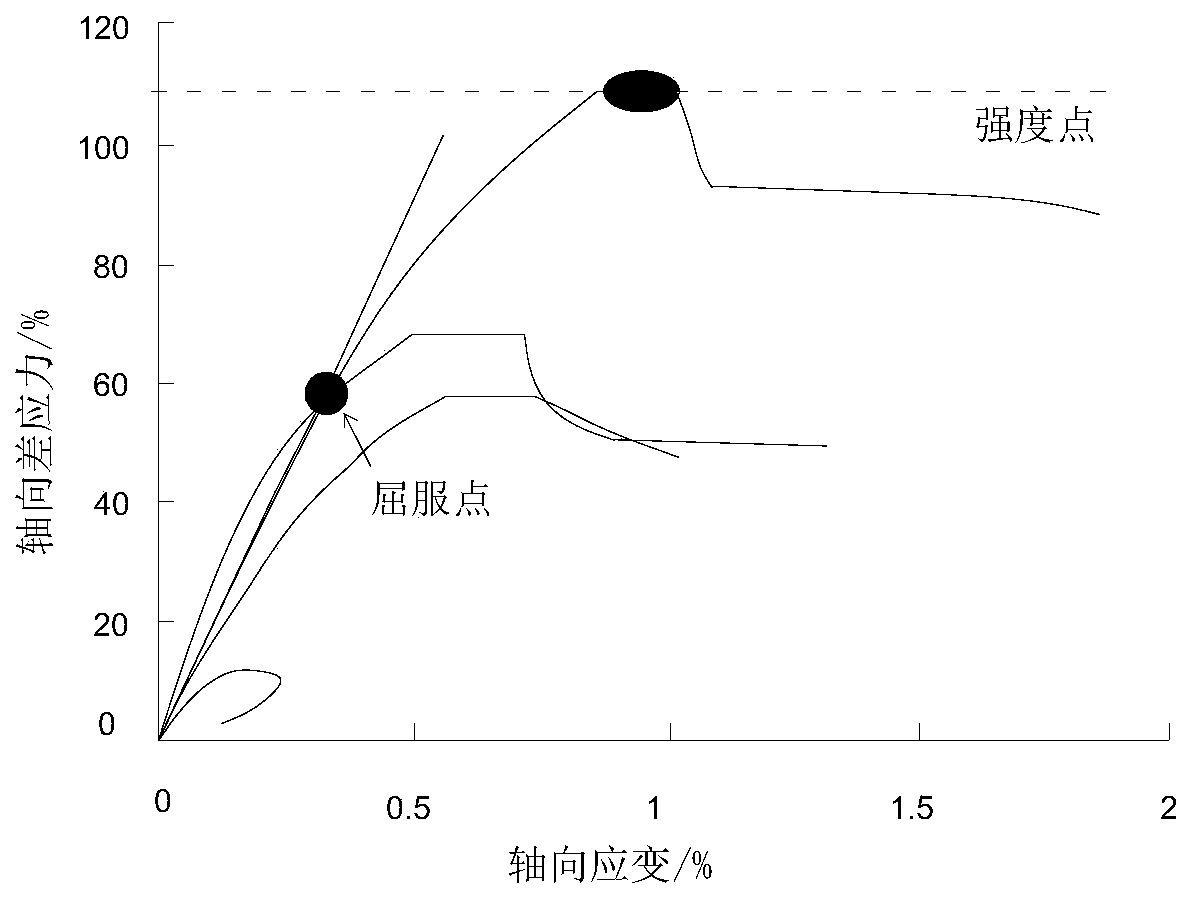

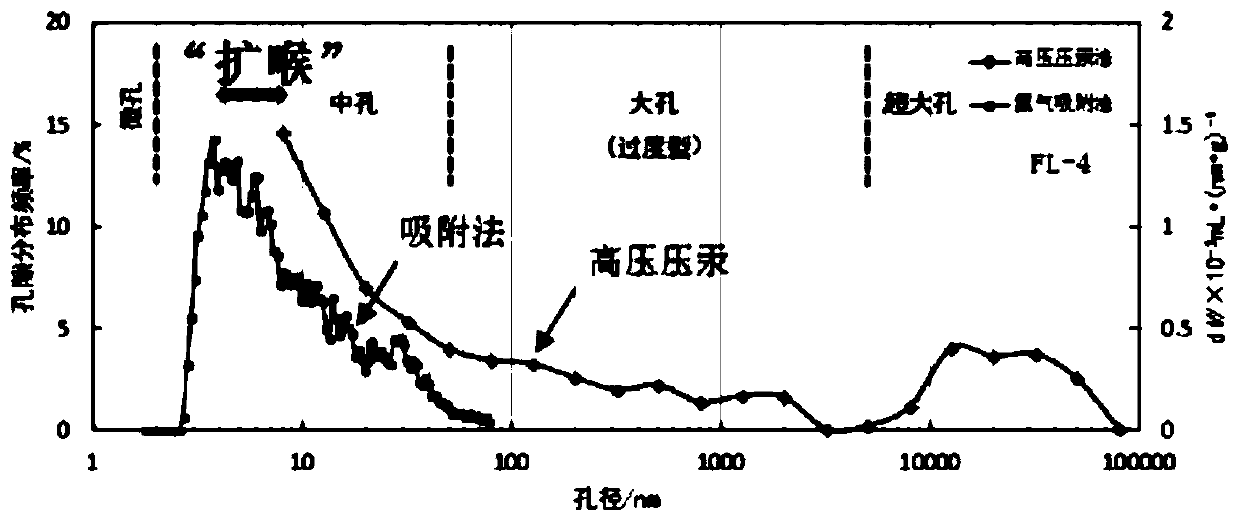

[0058] A group of mud shale samples collected at the same place were subjected to high-pressure mercury intrusion testing, and the first capillary pressure and the first pore throat radius rp were obtained 1 The relationship between. Determine the pore-throat radius that can be characterized by high-pressure mercury porosimetry. Carry out the adsorption method test on the same group of samples, the specific steps are as follows:

[0059] (1) Test the low-temperature nitrogen adsorption curve, and calculate the specific surface area and pore throat volume according to the BET equation.

[0060] Specific surface area S a The calculation formula is:

[0061] In the formula: S a is the specific surface area of shale; V m is the saturated adsorption capacity of nitrogen monomolecule; W is the weight of shale.

[0062] The calculation formula of pore throat volume is V=Vp;

[0063] In the formula: V is the nitrogen adsorption capacity; V p is the pore throat volume.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com