Automatic connector jack shell nosing mechanism

A technology of a connector and a driving mechanism, which is applied in the field of the automatic closing mechanism of the connector jack, can solve the problem of unstable insertion and pulling force of the jack, and achieve the effects of quantitative control, convenient operation and quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

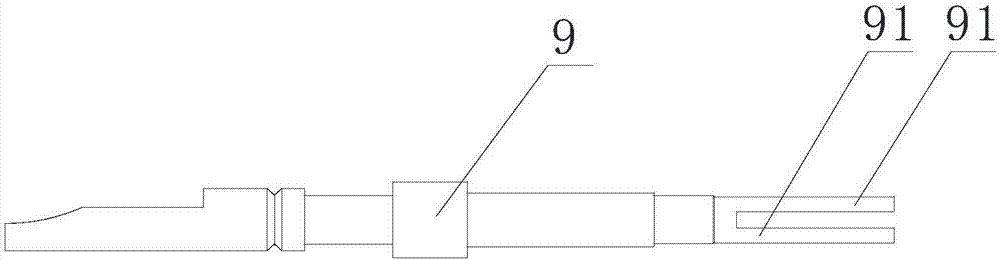

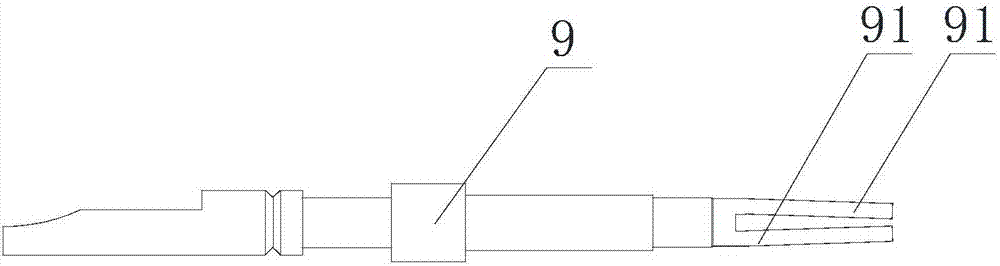

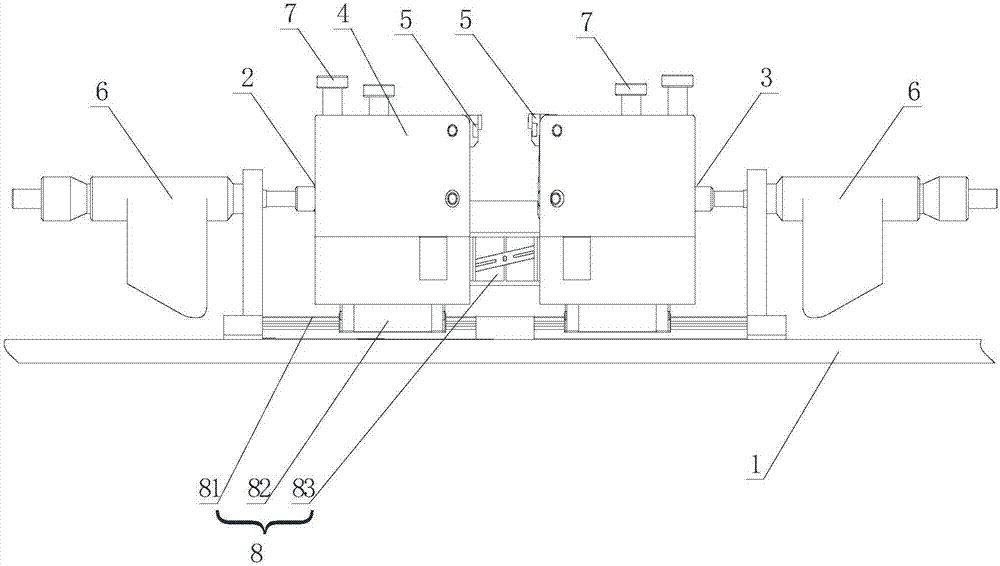

[0025] Such as image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, a connector jack automatic closing mechanism includes a bottom plate 1, a left closing component 2 and a right closing component 3. The left closing component 2 and the right closing component 3 are symmetrically arranged on the bottom plate 1. The left closing component 2 and the right closing component The closing assembly 3 includes a fixing block 4 and a closing riveting block 5. The closing riveting block 5 is arranged on the fixing block 4, the fixing block 4 is slidably connected to the bottom plate 1, and the fixing block 4 is provided with an adjustment for adjusting the inclination angle of the closing riveting block 5 Mechanism 6, the fixed block 4 is provided with a locking adjustment mechanism 6 to ensure that the inclination of the closing riveting block 5 does not change during the closing process. A locking mechanism 7 is provided on the bottom plate 1 to drive the left c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com