A multi-arm automatic rotary sprinkler

An automatic rotating and rotating head technology, applied in the field of atomization, can solve the problem that the multi-arm nozzle cannot spray the atomized solution, and achieve the uniform effect of the atomized solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

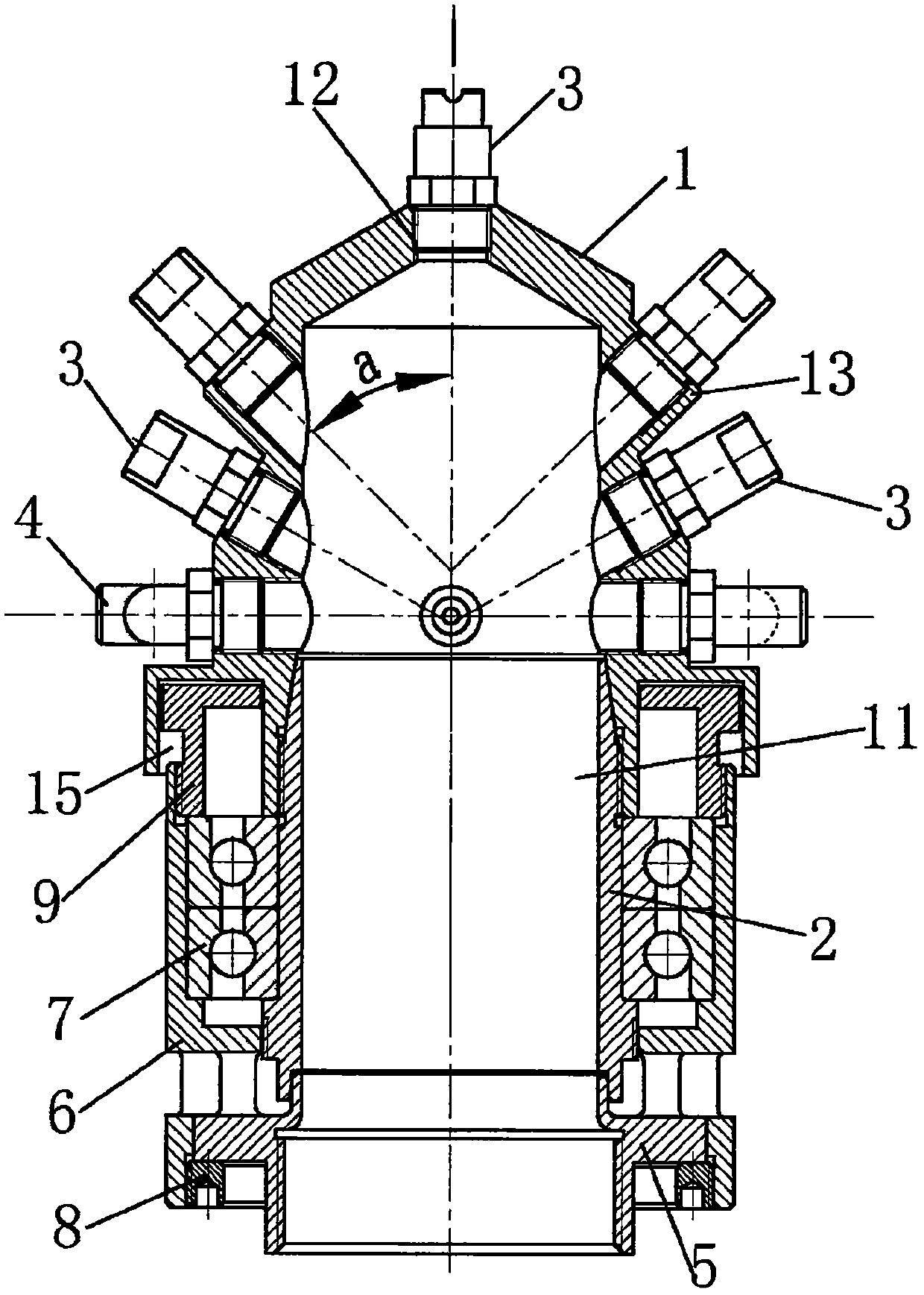

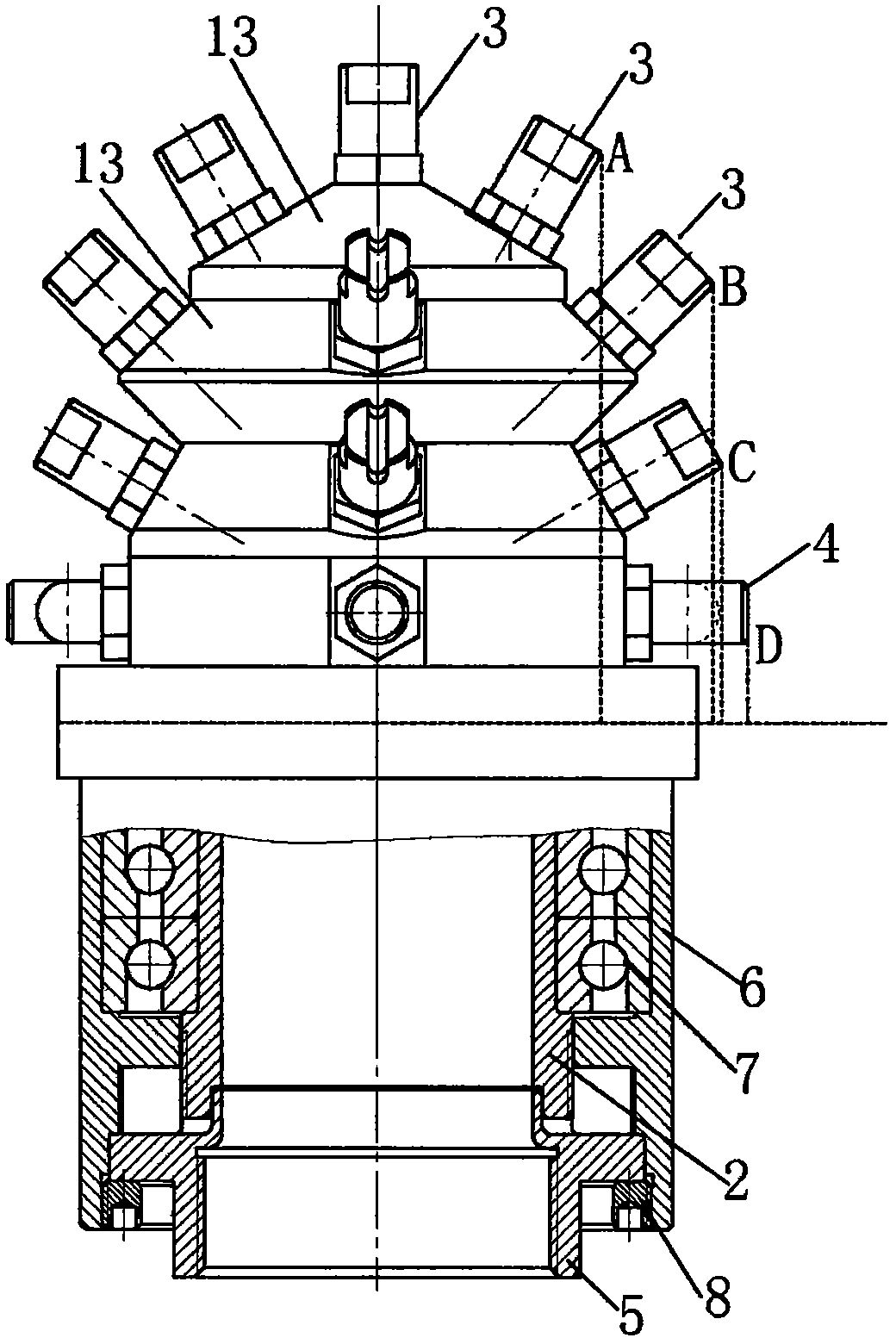

[0077] Such as figure 1 with figure 2 As shown, this embodiment provides a multi-arm type automatic rotary nozzle, including

[0078] stator;

[0079] The rotary head 1 is rotatably connected to the stator, has a fluid chamber and at least one fluid inlet 11 and several fluid outlets 12 communicated with the fluid chamber;

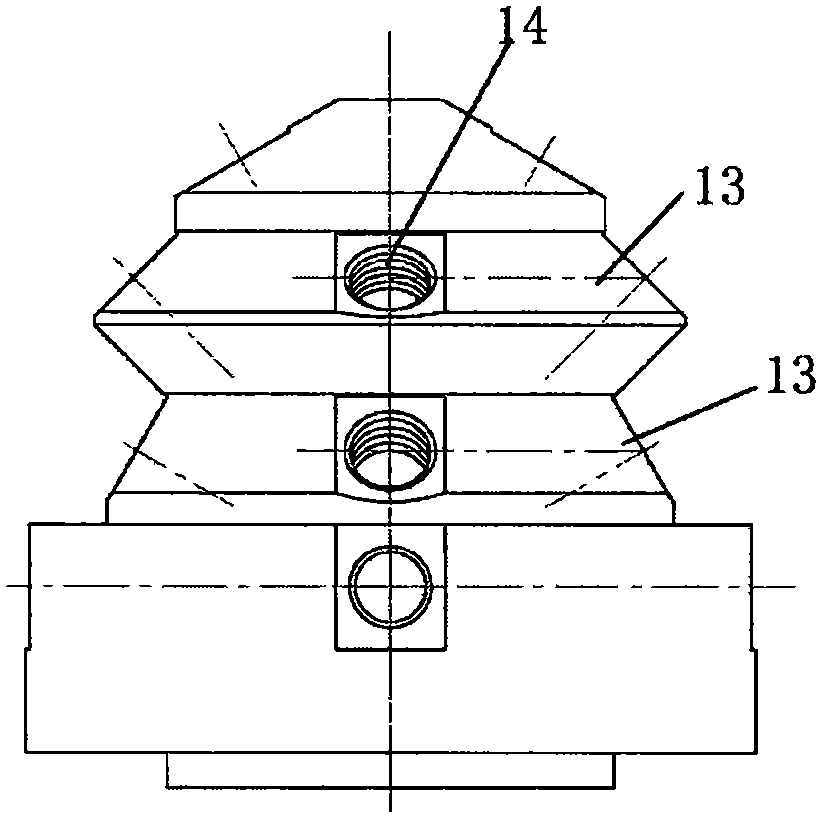

[0080] There are several nozzles 3, and each nozzle corresponds to a fluid outlet 12 installed on the swivel head 1, and its axis is inclined at a certain angle to the axis of the height direction of the swivel head 1; several nozzles 3 are formed along the height direction of the swivel head 1 There are at least two layers, and the included angle a formed by the axes of the nozzles 3 of the adjacent two layers and the axis of the height direction of the rotary head 1 is different;

[0081] There is at least one power nozzle 4, which is arranged on the rotary head 1 corresponding to the fluid outlet 12, and its axis is perpendicular to the axis of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com