Cold-rolled strip surface burr removing mechanism

A technology for removing burrs and cold-rolling steel strips, which is applied in the directions of grinding frames, parts of grinding machine tools, and machine tools suitable for grinding workpiece edges. Uneven strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

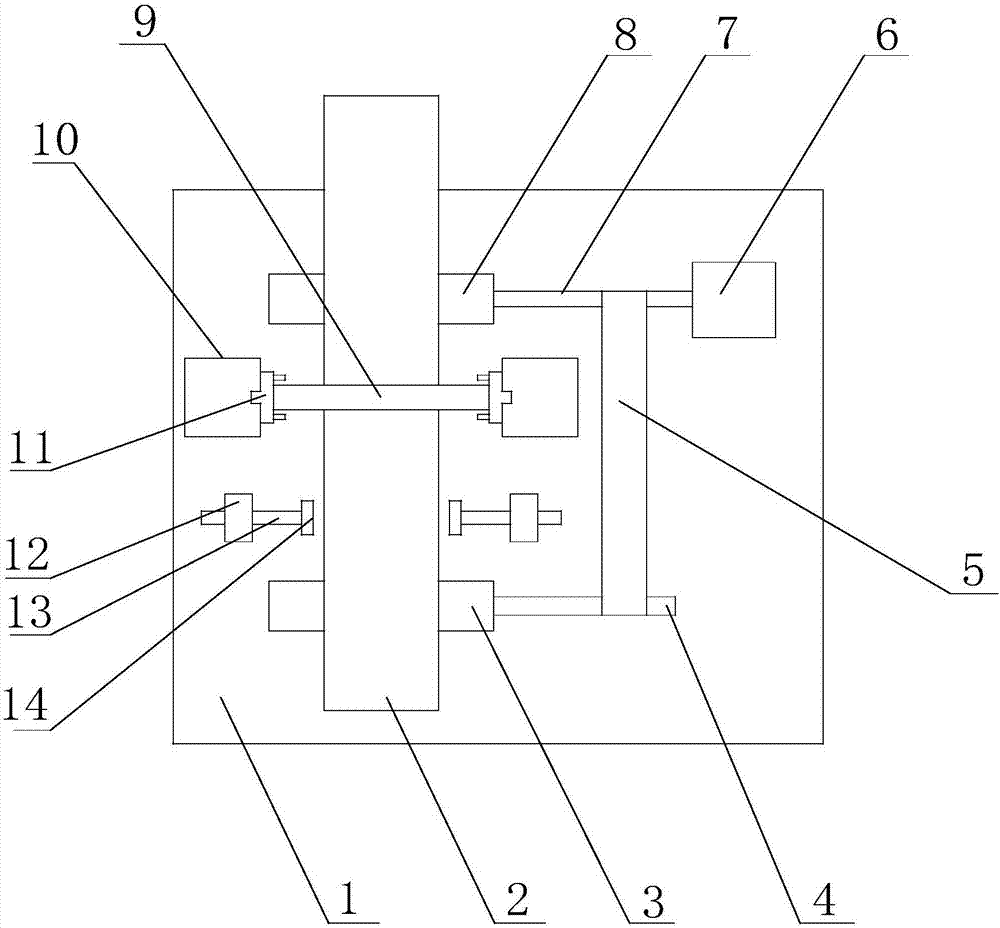

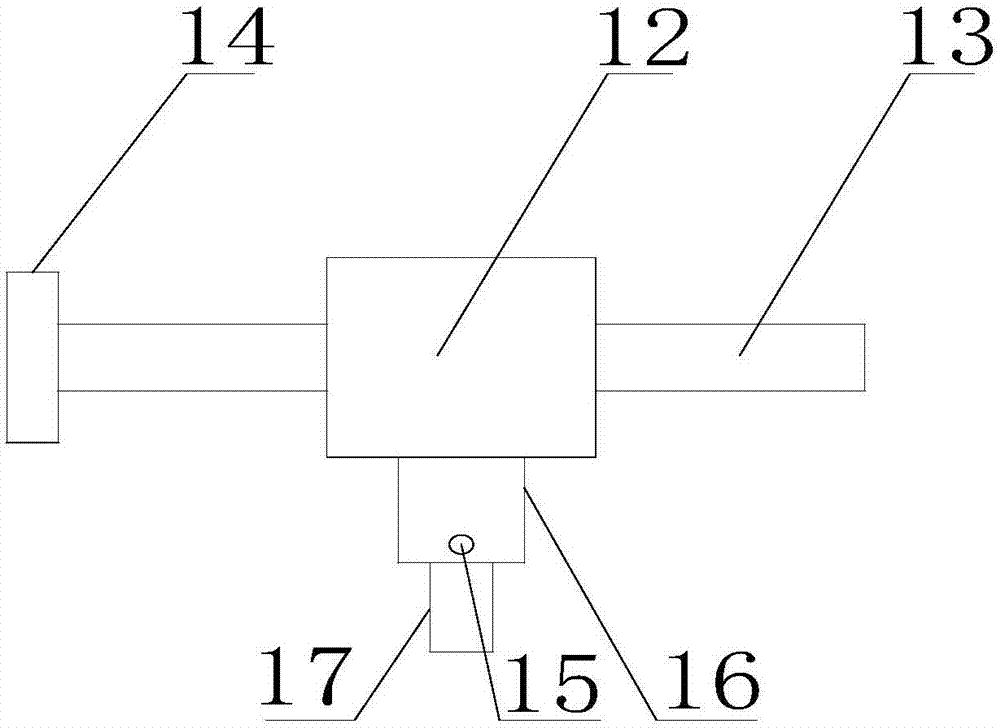

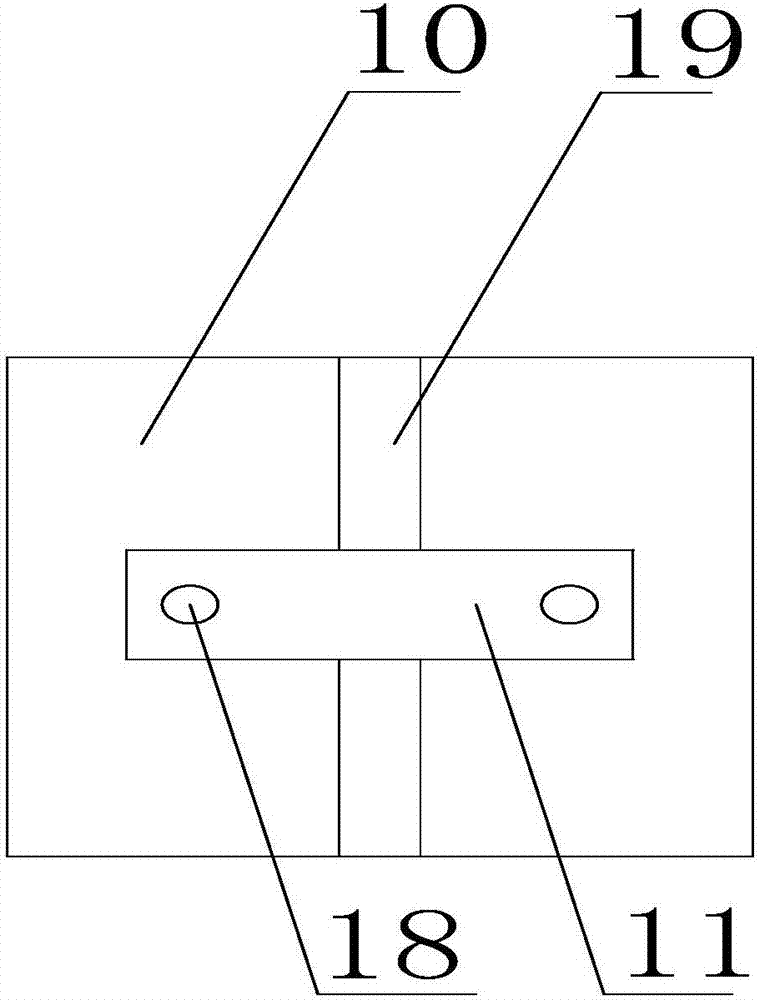

[0024] Such as Figure 1 to Figure 4 As shown, the cold-rolled strip surface deburring mechanism of the present invention comprises a base 1 and a motor 6, the motor 6 is located on the base 1, the top of the base 1 is provided with a first roller 3 and a second roller 8, the first roller The axis of 3 and the axis of the second roller 8 are on the same straight line, the first roller 3 and the second roller 8 can rotate on the base 1, the first roller 3 is provided with the first transmission rod 4, the second A transmission rod 4 is provided with a belt 5, the belt 5 is sleeved on the first transmission rod 4, the second roller 8 is provided with a second transmission rod 7, and the belt 5 is also sleeved on the second transmission rod 7, the second transmission One end of the rod 7 is connected with the second roller 8, and the other end is connected with the output end of the motor 6. When the motor 6 works, the output end of the motor 6 will drive the second transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com