A multi-scale design method for steel deck pavement of road-rail dual-purpose bridge

It is a technology with dual-use design method for highway and railway, which is applied in the field of bridge structure engineering, and can solve problems such as lack of consideration of the influence of railway bridges, damaged shear studs, and service life of steel mesh detail components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

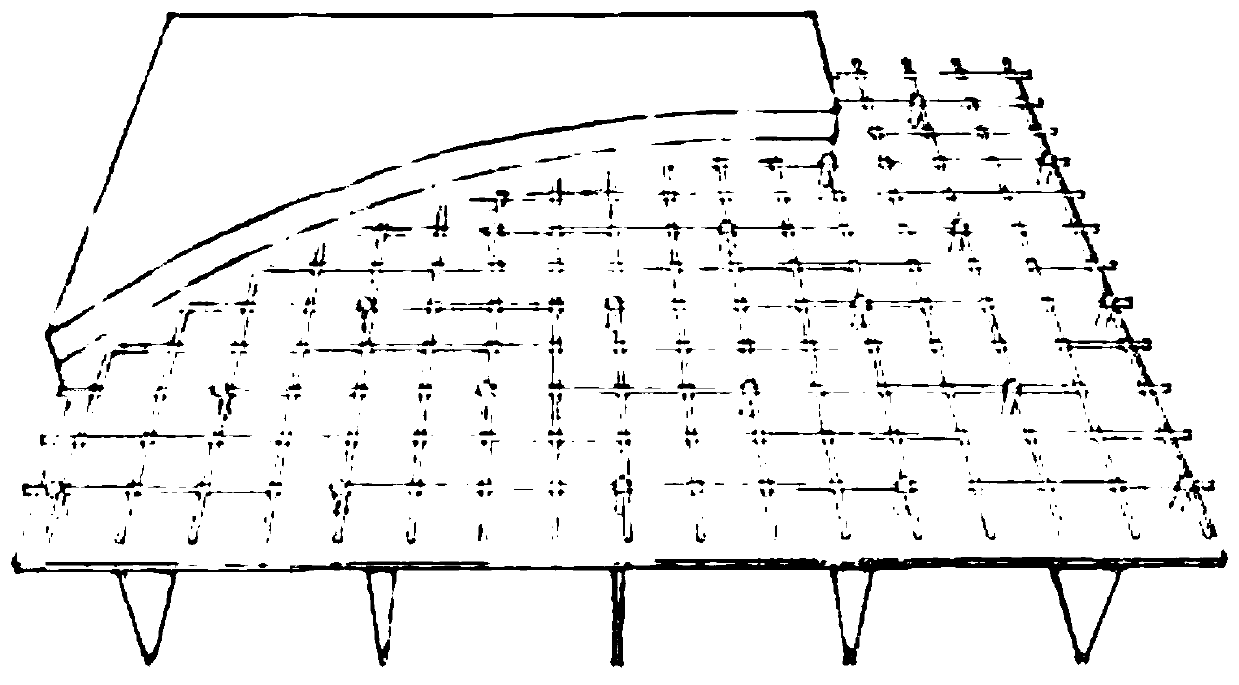

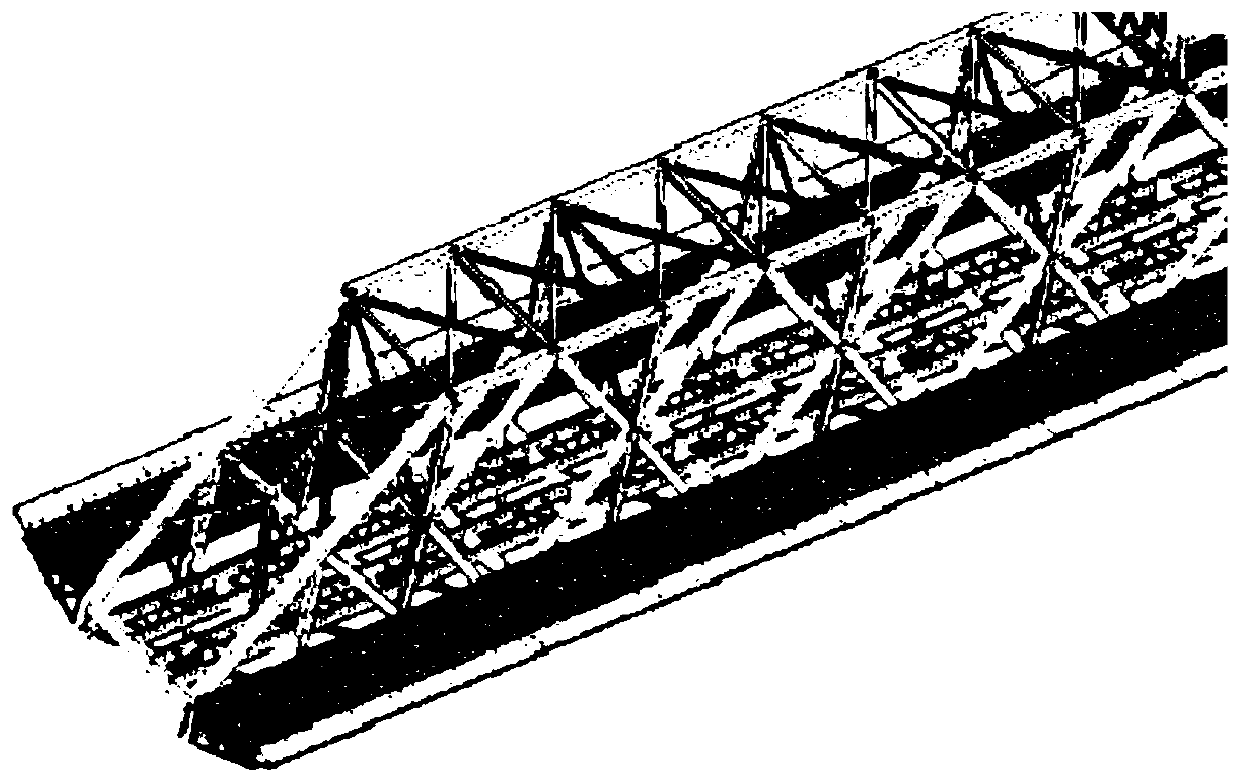

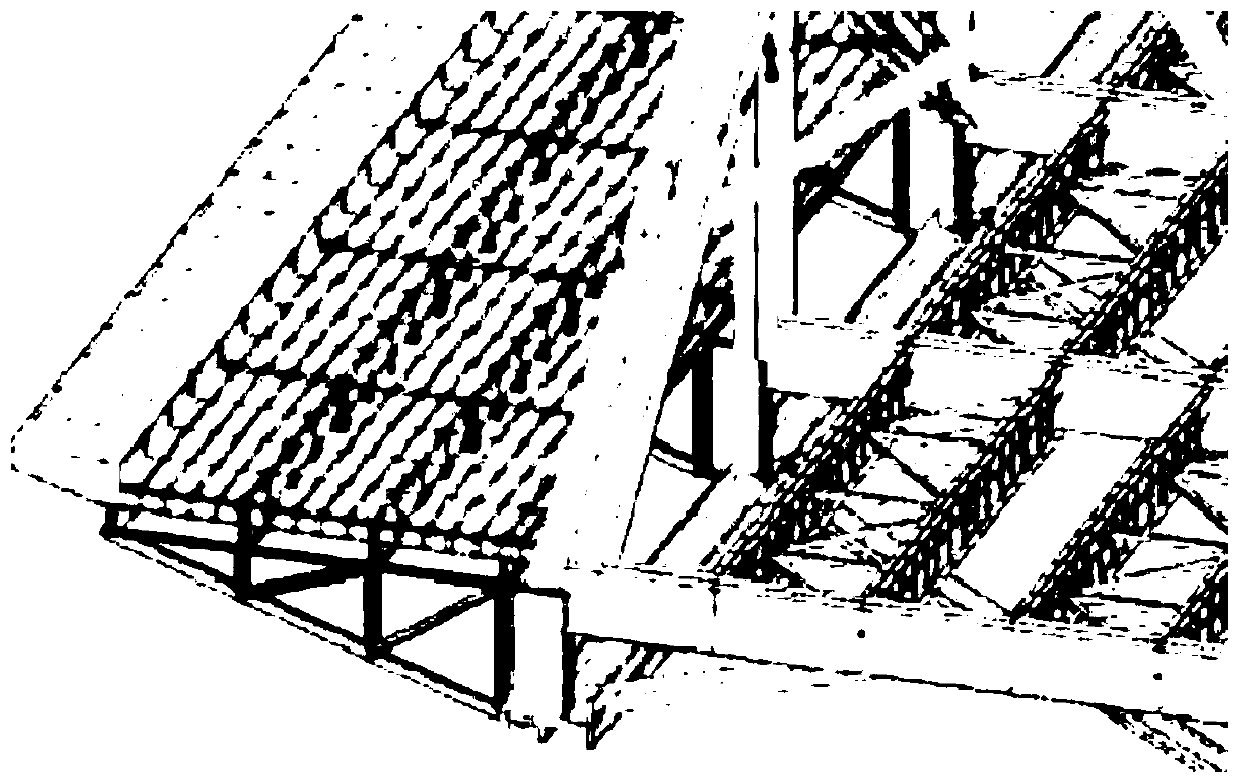

Image

Examples

Embodiment 1

[0070] This part compares the strain of the steel deck pavement under the coupling effect of the highway load and the railway load on the whole bridge model of the highway-railway bridge. For the value of road load, refer to "JTG D60-2015 General Code for Design of Highway Bridges and Culverts", and for the value of railway load, refer to "Basic Code for Design of Railway Bridges and Culverts TB10002.1 2005".

[0071] Table (1): Strain values of steel bridge deck pavement under coupled loads of road and railway (με)

[0072] project train load car load combined load Maximum longitudinal tensile strain 92.4 68.4 152 Maximum transverse tensile strain 33.9 47.8 81.7

[0073] From table (1) and Figure 8 It can be seen that the contribution rates of highway load and railway load to the maximum longitudinal tensile strain are 40% and 60%, respectively, and the contribution rates to the maximum transverse tensile strain are 58.5% and 41.5%, res...

Embodiment 2

[0075] As a shear member, shear studs are widely used in steel-concrete composite structures. Their important role is to bear the shear action between concrete and steel plates, and at the same time strengthen the integrity of steel bridge deck and pavement. This part compares and analyzes the influence of different shear stud diameters, spacing and heights on the stress of steel bridge deck pavement.

[0076] Table (2) Bearing state of steel bridge deck pavement with different shear stud spacing (MPa)

[0077] Shear stud spacing transverse tensile stress Longitudinal tensile stress transverse shear stress Longitudinal shear stress 300mm×300mm 0.58 0.542 0.356 0.902 400mm×400mm 0.6 0.563 0.387 0.987 500mm×500mm 0.679 0.684 0.499 1.176

[0078] Table (3) Bearing status of concrete pavement lower layer with different shear nail diameters (MPa)

[0079] Shear stud diameter transverse tensile stress Longitudinal tensi...

Embodiment 3

[0086] This part compares the influence of elastic modulus of different pavement materials on the stiffness of asphalt pavement.

[0087] Table (6) Influence of asphalt pavement stiffness (MPa)

[0088] Elastic modulus / MPa transverse tensile stress Longitudinal tensile stress transverse shear stress Longitudinal shear stress 400 0.03 0.032 0.131 0.128 800 0.028 0.031 0.129 0.125 1000 0.026 0.03 0.128 0.125 1200 0.025 0.029 0.127 0.124 1400 0.025 0.029 0.127 0.124

[0089] It can be seen from Table (6) that as the elastic modulus of the asphalt pavement increases, the stress indexes of the asphalt pavement decrease slightly, and after reaching 1200 MPa, the stress indexes of the asphalt pavement do not change. Considering the strength, durability and economy of asphalt pavement concrete comprehensively, choosing 1200MPa for concrete elastic modulus is a reasonable choice. When designing the steel deck pavement struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com