Preparation method of prepreg-vacuum auxiliary liquid forming workpiece

A vacuum-assisted, liquid forming technology, used in household components, other household appliances, household appliances, etc., can solve the problem of low porosity of single-sided finish products, and achieve improved out-of-plane mechanical properties, excellent performance, and strong complementarity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

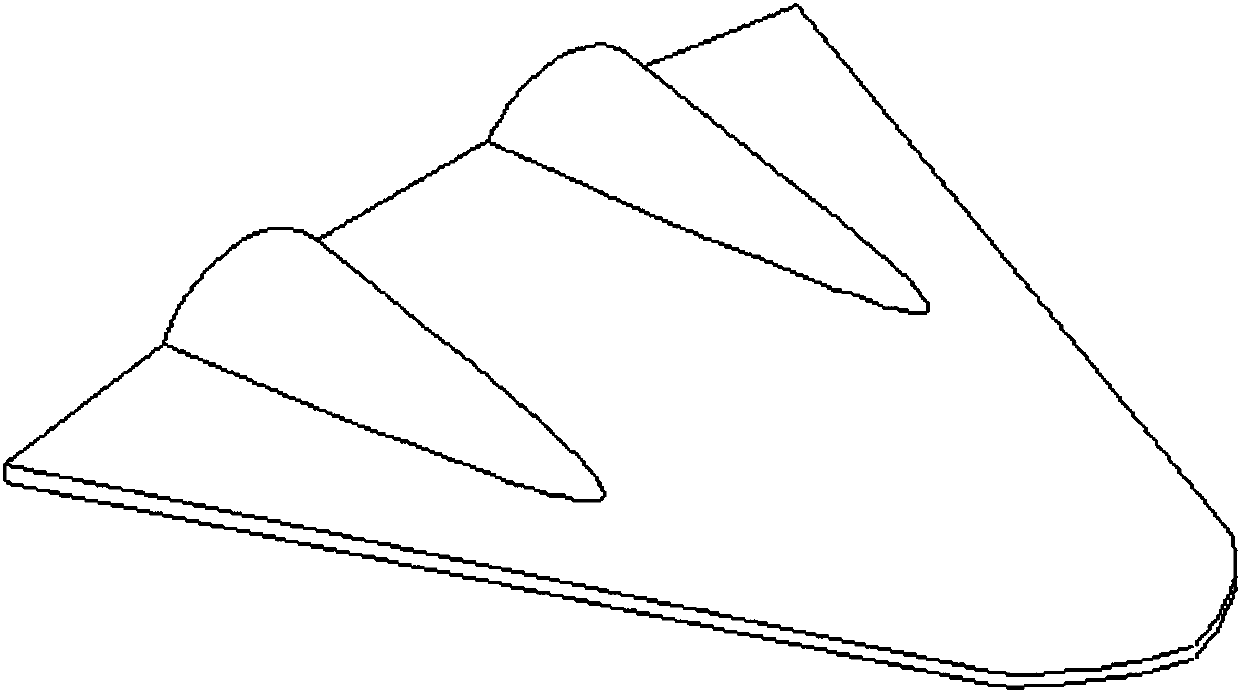

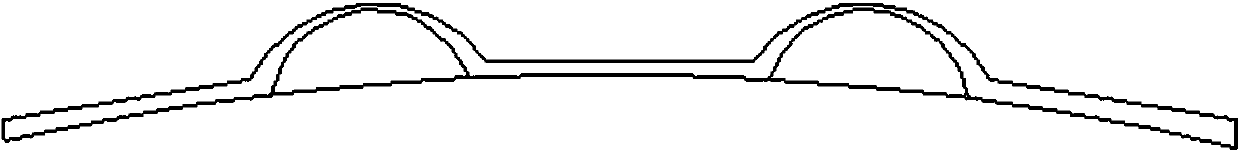

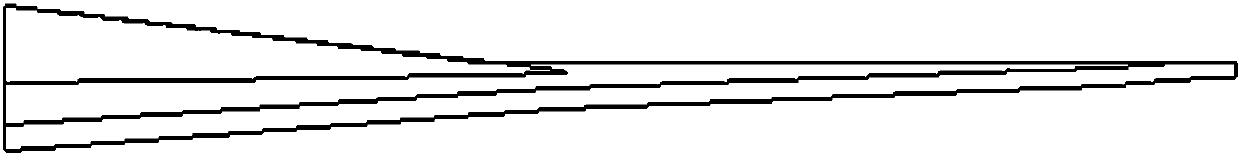

[0025] Such as Figure 1-3 Shown, the present invention is the preparation method of prepreg-vacuum assisted liquid forming article, and described preparation method comprises the following steps:

[0026] (1) Prepreg warming, cutting, and numbering: Take out the prepreg from the cold storage 6-8 hours before cutting, and return it to room temperature. After the prepreg is warmed up, import the prepreg cutting diagram into the cutting machine computer , cut the prepreg, write a sticky note according to the layer mark on the prepreg cutting diagram, and paste it on the cut prepreg, put the cut prepreg in a sealed bag and save it for later use;

[0027] (2) Heat setti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com